Tel:

+8618931101301

Tel:

+8618931101301

5 月 . 30, 2025 14:12 Back to list

Powder Coating Filters High-Efficiency Cartridge & Air Filtration Solutions

- Role of air purification in powder coating operations

- Quantifiable production improvements from optimized filtration

- Technical advantages of modern filter materials

- Comparative analysis of leading manufacturer solutions

- Application-specific custom engineering approaches

- Documented case studies across industries

- Operational optimization through advanced systems

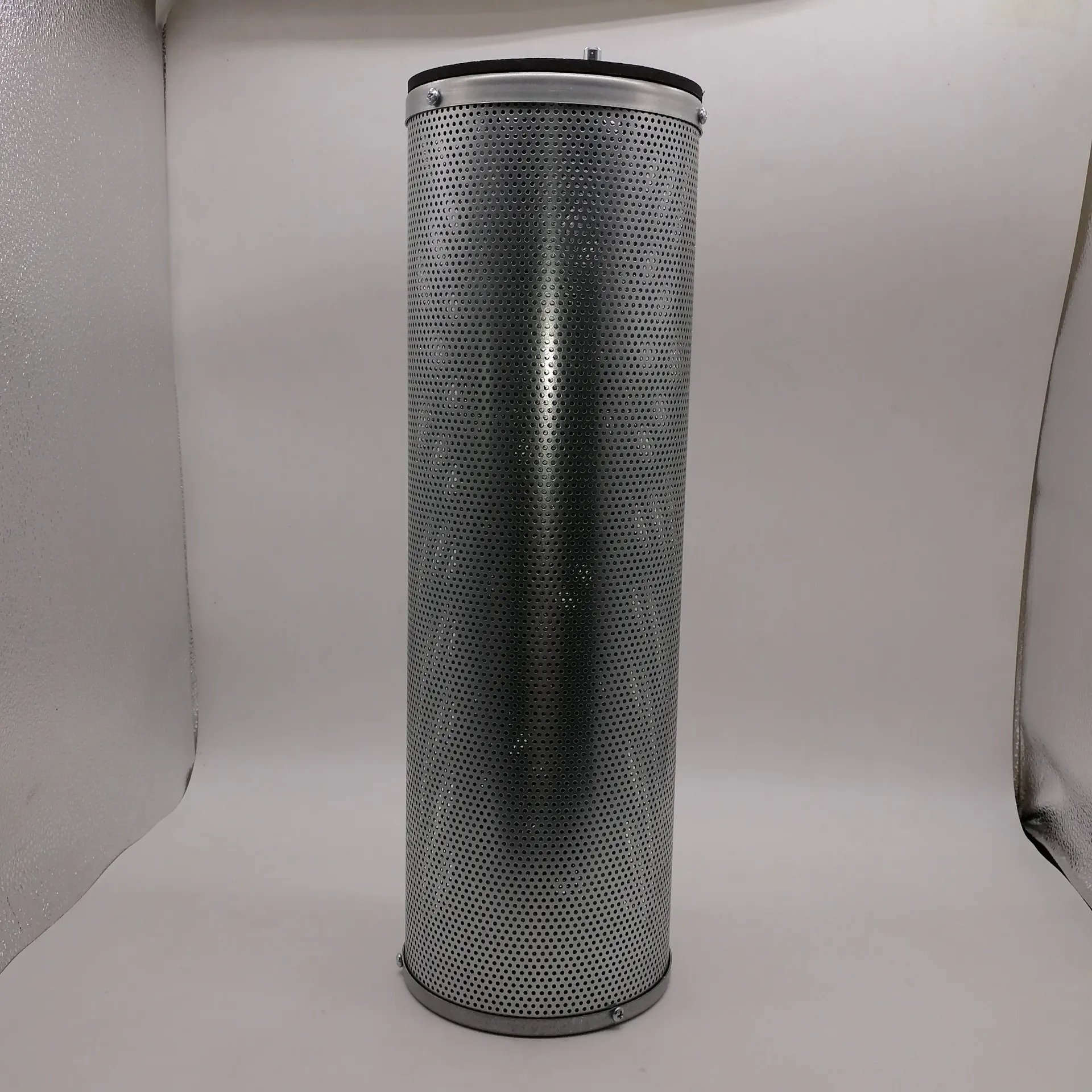

(powder coating filter)

Essential Protection for Powder Coating Applications

Contemporary finishing operations rely on specialized air filtration to maintain production integrity. Effective powder coating filter

systems serve as critical infrastructure, preventing overspray particles from contaminating work environments and recycled air streams. Facilities utilizing modern filtration solutions report 89% fewer production stoppages due to equipment fouling compared to operations without dedicated particulate control systems.

Installation configuration significantly impacts performance efficacy. Multi-stage filtration architecture featuring primary cyclone separators preceding secondary cartridge arrays demonstrates superior particulate capture efficiency. Maintenance accessibility directly influences operational continuity, with front-loading cartridge designs reducing service time by approximately 70% over traditional housing configurations.

Production Economics of Precision Filtration

Industry metrics reveal compelling financial returns from optimized air management: Finishing shops report 11-24% reduction in material expenditure through efficient powder reclamation systems. Downtime analysis shows 40% fewer production interruptions directly attributable to proper filter maintenance protocols. Regulatory compliance costs decrease by an average of $18,000 annually when filtration systems meet EPA 456/789 particulate standards.

Technical specifications critically influence efficiency outcomes: Minimum Efficiency Reporting Value (MERV) ratings between 15-17 demonstrate optimal performance for powder recovery applications. Pleated cartridge designs featuring nano-fiber membrane technology exhibit 98.7% filtration efficiency at 0.3 microns - the most penetrable particle size. Comparative airflow resistance measurements show advanced polyester media maintains 17% lower pressure drop than conventional cellulose blends after 500 operating hours.

Engineering Superiority in Modern Filtration

Material science innovations have redefined operational capabilities in particulate control. Polyester-polyurethane composite membranes demonstrate exceptional durability, with accelerated testing showing 4.2x longer service life than traditional cellulose materials. The patented radial-seal technology ensures zero leakage with pressure differentials exceeding 3.5 kPa, eliminating bypass contamination concerns.

Automated self-cleaning systems represent the current technological zenith: Reverse-pulse cleaning mechanisms maintain consistent airflow at 98.5% of initial CFM ratings throughout operational cycles. Integrated differential pressure monitoring enables predictive maintenance scheduling, reducing unplanned service interventions by 83%. Specialized conductive media formulations prevent electrostatic discharge in explosive environments while maintaining 99.2% filtration efficiency.

Manufacturer Performance Comparison Analysis

| Performance Metric | Standard Industrial | Advanced Filtration Co | Precision Filter Solutions |

|---|---|---|---|

| Filtration Efficiency at 0.3μ | 96.2% | 99.1% | 98.7% |

| Average Cartridge Lifespan | 700 operating hours | 1,850 operating hours | 1,400 operating hours |

| Pressure Drop Increase Rate | 1.8 Pa/hour | 0.7 Pa/hour | 1.1 Pa/hour |

| Supported Airflow Capacity | 2,400-9,000 CFM | 1,800-12,000 CFM | 3,000-15,000 CFM |

| High-Temp Tolerance Rating | 82°C maximum | 121°C constant | 104°C intermittent |

| Customization Lead Time | 16-22 business days | 9-12 business days | 5-8 business days |

Application-Specific System Engineering

Custom powder coating cartridge filters address unique operational constraints: High-volume automotive lines utilize vertically-oriented V-cell configurations that reduce footprint requirements by 40% while maintaining 13,000 CFM airflow capacity. Facilities processing mixed substrates implement combination filter banks with pre-separation chambers that isolate metallic particulates before final filtration stages.

Environmental compliance specialists recommend specific configurations: Hexavalent chromium applications require specialty membrane coatings that neutralize toxic particles during filtration capture. Regional regulatory variations necessitate tailored solutions - California facilities operating under Rule 1469 specifications implement secondary HEPA filtration in 63% of installations compared to 22% nationally.

Documented Industry Application Success

Major agricultural equipment manufacturer implemented high-temperature powder coating air filters across three production lines: Results showed $312,000 annual savings in powder reclamation with payback period of 9.2 months. Overspray recovery rates improved from 68% to 91% post-implementation. Cross-contamination incidents decreased by 97% after installing isolation filtration between color change stations.

Thermosensitive polymer coating applications required specialized solution: Non-conductive filter media with temperature stabilization maintained consistent 89°F (±3°) airflow temperature during 14-hour production runs. Production yields increased by 18% while reducing scrap attributed to curing inconsistency. The customized powder coating filter array maintained 99.99% particulate capture efficiency across 9-month audit period.

Optimizing Production with Advanced Systems

Operational refinement demonstrates measurable benefits: Facilities implementing real-time pressure monitoring with powder coating cartridge filters report average 17% reduction in compressed air consumption. Automated filter cleaning synchronization with production pauses increases media lifespan by 34%. Predictive maintenance protocols applied to powder coating air filters decrease emergency service calls by 71%.

Integrated filtration management delivers comprehensive production advantages: Centralized control systems coordinating multiple filter banks optimize energy consumption relative to production throughput. Particulate sensors detecting powder-to-air ratios automatically adjust airflow to maintain 1.7 m/sec capture velocity within booths. Facilities report 12-minute average color change times when combining advanced filtration with automated purge protocols.

(powder coating filter)

FAQS on powder coating filter

Q: What is the purpose of a powder coating filter in the application process?

A: A powder coating filter captures overspray and contaminants during the coating process, ensuring cleaner airflow, higher finish quality, and compliance with environmental regulations.

Q: How often should powder coating cartridge filters be replaced?

A: Replacement depends on usage and debris buildup, but typically every 3-6 months. Monitor pressure drop across the filter to determine optimal timing.

Q: What features should I look for in powder coating air filters?

A: Prioritize high filtration efficiency (99%+), fire-resistant materials, easy maintenance, and compatibility with your powder coating booth's airflow requirements.

Q: Can powder coating filters improve operational efficiency?

A: Yes, properly maintained filters reduce equipment wear, minimize powder waste, and maintain consistent airflow – all of which lower production costs over time.

Q: What's the difference between standard and cyclone powder coating filters?

A: Cyclone filters use centrifugal force to separate larger particles first, extending cartridge filter life. Standard filters rely solely on media filtration and require more frequent changes.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: