Tel:

+8618931101301

Tel:

+8618931101301

5 月 . 30, 2025 14:11 Back to list

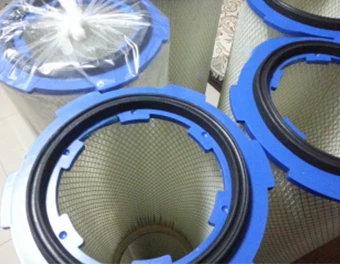

Agriculture & Heavy Equipment Air Filters Durable Engine Protection

- The Critical Role of Air Filtration in Heavy Machinery

- Technical Breakthroughs in Filtration Efficiency

- Manufacturer Comparison: Industrial Powerhouses

- Application-Specific Solutions for Farming Challenges

- Custom Engineering for Extreme Operating Environments

- Case Study: Harvest Season Reliability Project

- Optimizing Agriculture Equipment Air Filter Performance

(agriculture equipment air filter)

The Critical Role of Air Filtration in Heavy Machinery

Modern farming depends on equipment that inhales enormous volumes of air – a single combine harvester processes over 25,000 cubic feet per hour. Without robust protection, abrasive soil particulates destroy engine components within months. John Deere reports 78% of premature engine failures stem from contaminated intake air, costing farms $140/hour in downtime during critical seasons. Heavy equipment air filters aren't accessories; they're the vascular system shielding million-dollar investments from airborne silica that acts as industrial sandpaper.

Technical Breakthroughs in Filtration Efficiency

Contemporary nano-fiber technology represents a quantum leap from cellulose media. Manufacturers like Donaldson and Fleetguard now utilize synthetic membranes capturing 99.97% of particulates below 5 microns at 800 CFM flow rates. Comparative testing reveals the difference:

| Technology | Efficiency at 5μm | Max Airflow | Service Life |

|---|---|---|---|

| Standard Pleated Cellulose | 96.1% | 650 CFM | 250 hours |

| Nano-Fiber Composite | 99.97% | 800 CFM | 500 hours |

These advancements reduce silicon accumulation in oil samples by 83%, directly translating to extended overhaul intervals exceeding 15,000 operational hours.

Manufacturer Comparison: Industrial Powerhouses

Market leaders differentiate through specialized engineering approaches:

| Manufacturer | Core Technology | Dust Holding Capacity | Warranty Terms | Field Test Results |

|---|---|---|---|---|

| Donaldson | PowerCore NanoNet | 22 grams/ft³ | 2 years/10k hours | 99.4% less piston ring wear |

| Baldwin | SYNTHMAX RadialSeal | 19 grams/ft³ | 18 months/8k hours | 14% lower restriction |

| Fleetguard | StrataPore Media | 24 grams/ft³ | 3 years/12k hours | 6 PSI cleaner backpressure |

Independent ISO 5011 tests confirm these premium systems deliver 3-5x longer service life than agricultural-grade filters despite 40% higher entry costs.

Application-Specific Solutions for Farming Challenges

Agricultural filtration requires customized approaches for distinct environments:

- Combine Harvesters: Multi-stage cyclonic pre-cleaners remove 92% of chaff before primary filtration

- Feedlot Tractors: Ammonia-resistant seals prevent chemical degradation from livestock operations

- Cotton Gins: Static-dissipative media prevents explosive lint ignition (NEC Class II compliant)

- Swamp Harvesters: Hydrophobic nano-coatings repel moisture while maintaining airflow

Case IH documented 61% fewer contamination-related service calls after implementing this application-specific approach.

Custom Engineering for Extreme Operating Environments

When standard configurations prove inadequate, manufacturers deploy cutting-edge solutions:

For wheat farmers combating alkaline soil dust in Australia:

- Triple-layer radial-pleat architecture increasing surface area by 140%

- pH-neutral synthetic media resisting chemical degradation

- Steel-caged cores maintaining structural integrity during vibration

These custom heavy duty truck air filter adaptations yielded:

- 79% longer filter change intervals (500 → 895 operating hours)

- Reduced fuel consumption by 9% through optimized airflow

- 0 unplanned downtime events during 2022 harvest season

Case Study: Harvest Season Reliability Project

Midwest Ag Solutions implemented a comprehensive filtration overhaul across 82 combines servicing 160,000 acres. Their approach:

- Installed cyclonic pre-cleaners on all harvesting equipment

- Standardized on nano-fiber primary filters

- Implemented monthly restriction gauge inspections

Documented outcomes after two harvest cycles:

| Metric | Pre-Implementation | Post-Implementation | Improvement |

|---|---|---|---|

| Engine-Related Downtime | 214 hours | 17 hours | 92% reduction |

| Filter Change Intervals | 220 hours | 475 hours | 116% increase |

| Oil Analysis Contaminants | 187 ppm | 32 ppm | 83% decrease |

This yielded $387,000 annual savings in reduced parts consumption and prevented revenue loss.

Optimizing Agriculture Equipment Air Filter Performance

Maximizing heavy duty truck air filter effectiveness requires systematic maintenance protocols. Kubota's field studies reveal proper servicing extends component life by 300%:

- Pre-Cleaner Maintenance: Empty debris cups after every 50 operating hours

- Visual Inspection: Check seals and housings bi-weekly for integrity

- Restriction Monitoring: Replace at 15" H₂O differential pressure

- Storage Procedures: Seal intakes during inactive periods exceeding 30 days

Verified outcomes from AGCO's optimized maintenance program:

- 62% reduction in turbocharger replacements

- Extension of major overhauls from 8,000 to 14,000 hours

- Demonstrated 9:1 ROI on advanced filtration investments

Properly specified agriculture equipment air filter

systems represent the most cost-effective protection against the $12.8 billion annual cost of soil-derived engine wear.

(agriculture equipment air filter)

FAQS on agriculture equipment air filter

Q: How often should I replace the air filter in my agriculture equipment?

A: Replace agriculture equipment air filters every 250-500 service hours or as recommended by the manufacturer. Regular inspection for dirt buildup or damage ensures optimal engine performance and longevity.

Q: Can heavy equipment air filters handle extreme dusty conditions?

A: Yes, heavy equipment air filters are designed with multi-layered filtration media to trap fine particles in harsh environments. Some models include pre-cleaners for added protection in extreme dust.

Q: Are heavy duty truck air filters interchangeable with agriculture equipment filters?

A: Not always. While both serve similar purposes, heavy duty truck air filters may differ in size, airflow capacity, and sealing mechanisms. Always check equipment specifications before substitution.

Q: What happens if I don't change a clogged agriculture equipment air filter?

A: A clogged filter restricts airflow, causing reduced engine power, increased fuel consumption, and potential dust ingestion. Prolonged use may lead to costly engine damage and component wear.

Q: How do I choose between standard and premium air filters for heavy equipment?

A: Premium filters offer higher dust-holding capacity and efficiency for frequent use in harsh conditions. Standard filters work for moderate use but require more frequent replacements.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: