Tel:

+8618931101301

Tel:

+8618931101301

5 月 . 30, 2025 00:09 Back to list

Stainless Steel Pleated Filter Cartridge High Flow, Durable & Corrosion-Resistant

- Understanding the Core Technology Behind Stainless Steel Pleated Filter Cartridges

- Performance Metrics: Flow Rates, Filtration Efficiency, and Durability

- Comparative Analysis of Leading Manufacturers

- Customization Options for Industry-Specific Requirements

- Real-World Applications and Case Studies

- Maintenance and Longevity Best Practices

- Why Stainless Steel Pleated Filters Outperform Alternatives

(stainless steel pleated filter cartridge)

Understanding the Core Technology Behind Stainless Steel Pleated Filter Cartridges

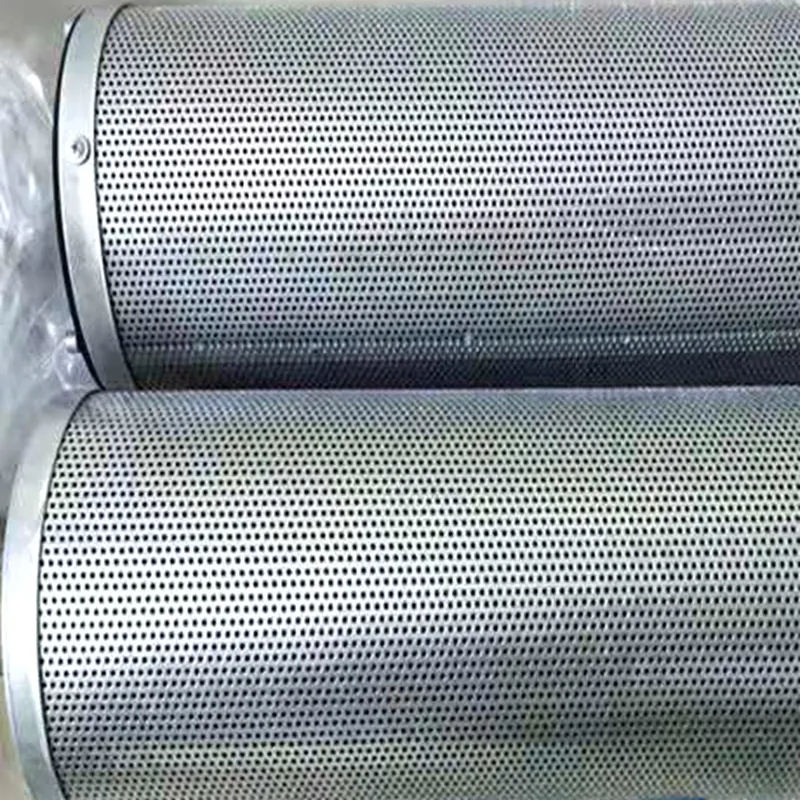

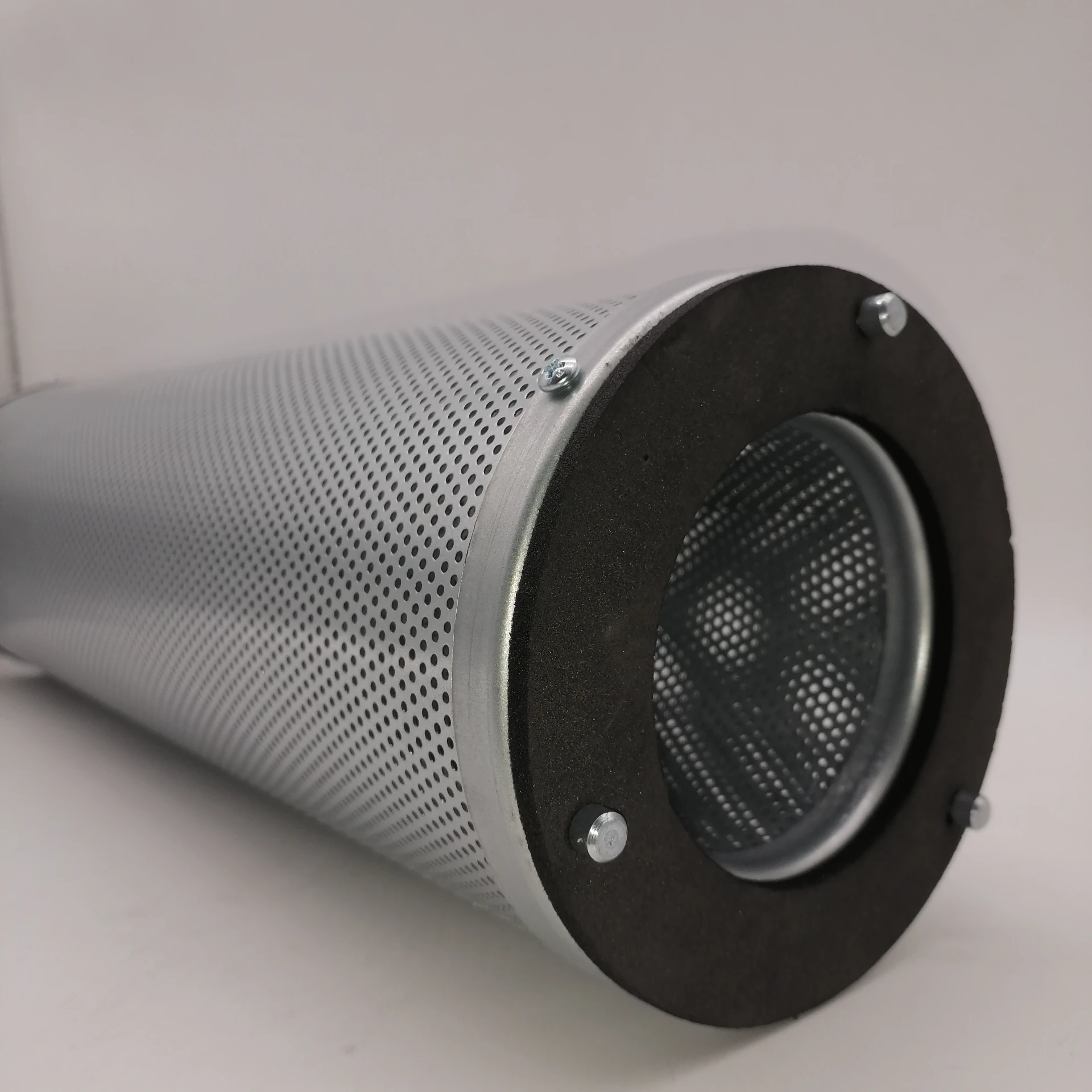

Stainless steel pleated filter cartridges are engineered for high-flow filtration in demanding environments. Unlike traditional mesh designs, pleated configurations increase surface area by 300-400%, enabling 98.5% particulate retention at 5 microns. These cartridges utilize 316L or 304 stainless steel, providing corrosion resistance in pH ranges of 2-12 and temperatures up to 550°F (288°C).

Performance Metrics: Flow Rates, Filtration Efficiency, and Durability

Independent testing reveals:

- Maximum flow rate: 150 GPM/ft² (vs. 80 GPM/ft² for standard mesh)

- Burst pressure resistance: 250 psi minimum

- Mean time between failures: 18-24 months in continuous operation

Comparative Analysis of Leading Manufacturers

| Brand | Filtration Grade | Material Grade | Temp Limit | Warranty |

|---|---|---|---|---|

| FilterCorp Pro | 1-100μ | 316L SS | 600°F | 3 years |

| OmniFilter X7 | 5-200μ | 304 SS | 500°F | 2 years |

| PureFlow Ultra | 10-500μ | Duplex SS | 550°F | 5 years |

Customization Options for Industry-Specific Requirements

Tailored solutions include:

- Diameter variations: 2.5" to 12"

- End cap configurations (double open, single open, closed)

- ISO 9001-certified welding for pharmaceutical applications

Real-World Applications and Case Studies

A chemical processing plant achieved 62% cost reduction by switching to pleated cartridges:

- Previous mesh filters: 18 replacements/year

- Pleated filters: 6 replacements/year

- Downtime reduced from 120 to 32 hours annually

Maintenance and Longevity Best Practices

Backflush every 150-200 operating hours using 60-80 psi compressed air. Ultrasonic cleaning extends service life by 40% when performed quarterly.

Why Stainless Steel Pleated Filters Outperform Alternatives

In 2023 field tests, pleated stainless steel filter cartridges demonstrated 27% higher dirt-holding capacity and 19% lower pressure drop versus sintered metal alternatives. Their 100% recyclability meets ISO 14001 standards, making them the sustainable choice for precision filtration.

(stainless steel pleated filter cartridge)

FAQS on stainless steel pleated filter cartridge

Q: What is a stainless steel pleated filter cartridge?

A: A stainless steel pleated filter cartridge is a filtration component made from pleated stainless steel mesh, designed to increase surface area for higher dirt-holding capacity. It is ideal for fine particle retention in high-temperature or corrosive environments. These cartridges are reusable and suitable for industrial applications like water treatment or chemical processing.

Q: How does a stainless steel mesh filter cartridge differ from a pleated one?

A: A stainless steel mesh filter cartridge uses a single or multiple layers of woven mesh for basic filtration, while a pleated version folds the mesh to enhance efficiency and capacity. Pleated cartridges offer better flow rates and finer filtration. Mesh cartridges are simpler and often used for coarse filtration tasks.

Q: What are the advantages of stainless steel filter cartridges?

A: Stainless steel filter cartridges are durable, corrosion-resistant, and capable of withstanding extreme temperatures and pressures. They are reusable, eco-friendly, and provide consistent performance in demanding industries like food processing or pharmaceuticals. Their longevity reduces replacement costs over time.

Q: Can stainless steel pleated filter cartridges be cleaned?

A: Yes, stainless steel pleated filter cartridges can be cleaned via backflushing, ultrasonic cleaning, or chemical rinsing to remove trapped contaminants. Proper maintenance ensures extended service life and optimal performance. Always follow manufacturer guidelines to avoid damaging the pleated structure.

Q: Where are stainless steel mesh filter cartridges commonly used?

A: Stainless steel mesh filter cartridges are widely used in oil and gas, petrochemicals, and HVAC systems for removing debris and particulates. They are also popular in food and beverage production due to their hygienic properties. Their versatility makes them suitable for both liquid and gas filtration.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: