ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 14, 2025 11:03 Back to list

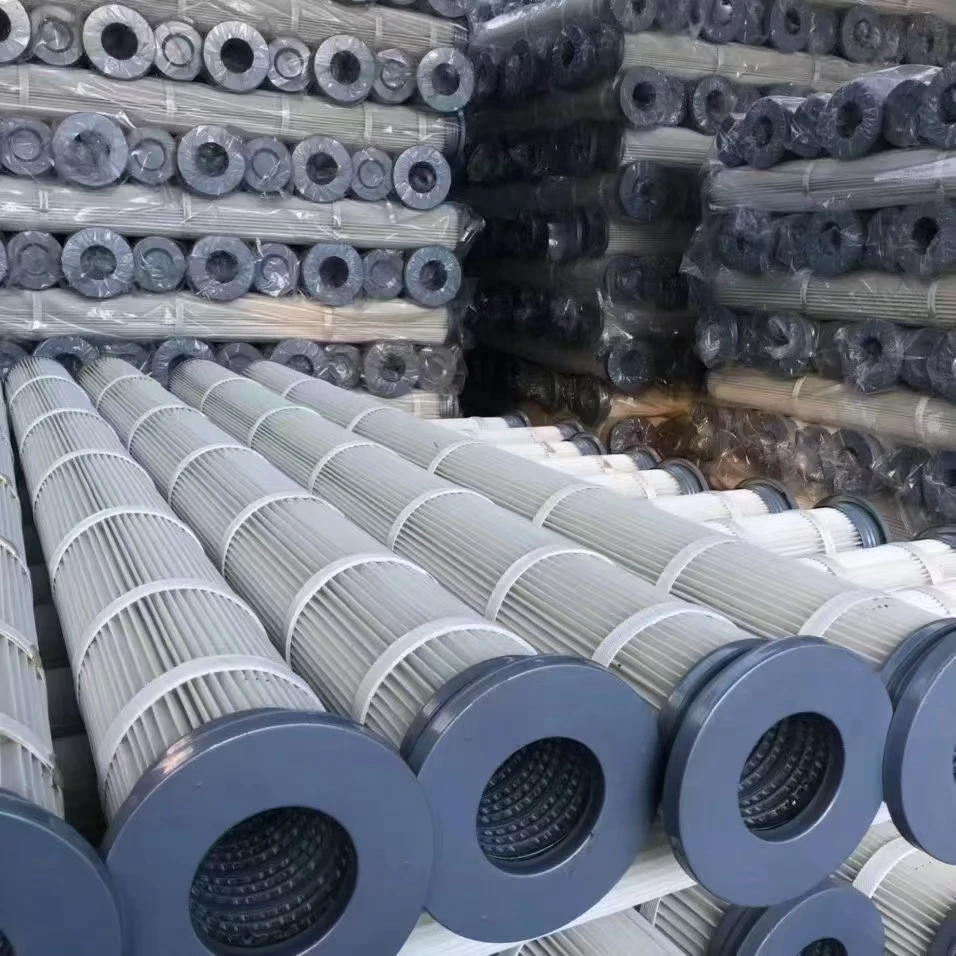

mini excavator air filter

Mini excavators have become an essential piece of equipment in the construction and landscaping industries, offering the versatility of larger machines with the compact size necessary for more confined spaces. At the heart of these machines lies the air filter, a critical component that ensures the mini excavator performs efficiently and remains reliable throughout its operational life. Maintaining a clean and functional air filter is crucial to maximizing both the performance and durability of the equipment.

Trustworthiness in maintaining mini excavator air filters also involves utilizing genuine, high-quality replacement parts. Generic or improperly sized air filters may not seal correctly, allowing unfiltered air to bypass the filter and enter the engine. It is always recommended to purchase air filters from reputable sources or directly from the equipment manufacturer to ensure they meet the necessary standards and specifications. To further enhance the air filter's efficiency, operators can consider additional protective measures, such as using a pre-cleaner. A pre-cleaner can be mounted before the air filter to remove larger particles, thereby extending the life and performance of the primary air filter. This proactive step can be particularly beneficial in high-dust environments, adding another layer of filtration and reducing the frequency of filter changes. Educating operators on the significance of regular air filter checks is essential for sustained equipment performance. Providing training on recognizing signs of filter failure and teaching the correct procedure for inspection and replacement can prevent unnecessary downtime and maintain operational efficiency. Proper documentation of filter maintenance also ensures that each piece of equipment receives consistent care over its lifespan. Ultimately, the air filter in a mini excavator is a small but mighty component with a significant impact on the machine's reliability and efficiency. Regular maintenance, utilizing the right filter type, and following manufacturer guidelines are all steps that contribute to the longevity and high performance of the construction equipment. Operators and maintenance personnel equipped with this knowledge can ensure that their mini excavators remain productive and effective, regardless of the environmental challenges they may face.

Trustworthiness in maintaining mini excavator air filters also involves utilizing genuine, high-quality replacement parts. Generic or improperly sized air filters may not seal correctly, allowing unfiltered air to bypass the filter and enter the engine. It is always recommended to purchase air filters from reputable sources or directly from the equipment manufacturer to ensure they meet the necessary standards and specifications. To further enhance the air filter's efficiency, operators can consider additional protective measures, such as using a pre-cleaner. A pre-cleaner can be mounted before the air filter to remove larger particles, thereby extending the life and performance of the primary air filter. This proactive step can be particularly beneficial in high-dust environments, adding another layer of filtration and reducing the frequency of filter changes. Educating operators on the significance of regular air filter checks is essential for sustained equipment performance. Providing training on recognizing signs of filter failure and teaching the correct procedure for inspection and replacement can prevent unnecessary downtime and maintain operational efficiency. Proper documentation of filter maintenance also ensures that each piece of equipment receives consistent care over its lifespan. Ultimately, the air filter in a mini excavator is a small but mighty component with a significant impact on the machine's reliability and efficiency. Regular maintenance, utilizing the right filter type, and following manufacturer guidelines are all steps that contribute to the longevity and high performance of the construction equipment. Operators and maintenance personnel equipped with this knowledge can ensure that their mini excavators remain productive and effective, regardless of the environmental challenges they may face.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: