ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 14, 2025 10:41 Back to list

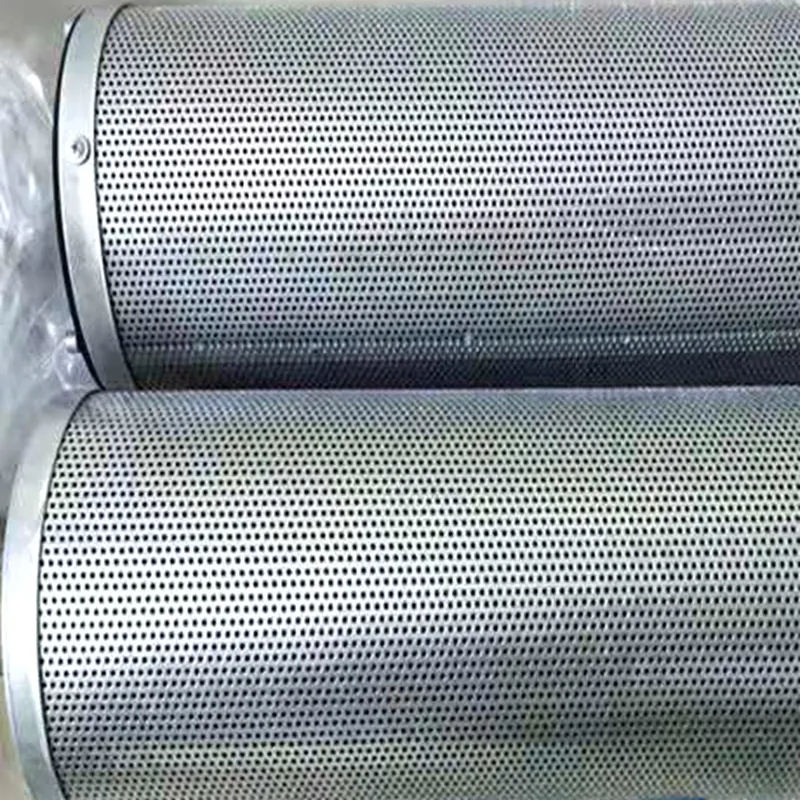

loader air filter

Loader air filters are a crucial component in maintaining the optimal performance and longevity of heavy machinery. Anyone involved in the construction, agricultural, or industrial sectors understands the necessity of keeping equipment in peak condition. The air filter plays a pivotal role in this, preventing dust, dirt, and other contaminants from entering the engine and causing damage. Choosing the right loader air filter involves understanding its importance, recognizing the signs of a failing filter, and knowing how to select the best one for your specific equipment.

Additionally, trust in a brand or supplier is paramount. In a market where many options are available, choosing a supplier with a proven track record of reliability and quality can make all the difference. Read reviews and customer testimonials, and look for certifications that vouch for the product's credibility. A trustworthy supplier will often offer guidance and support, ensuring their products deliver optimal performance. In essence, the experience of many seasoned professionals reinforces the importance of not taking shortcuts with loader air filters. A correlation between consistent, top-notch performance, and regular maintenance includes investing time and perhaps more resources upfront to ensure you have the best components for your equipment. The long-term benefits not only reflect in savings on repairs and fuel costs but also in the extended life and reliability of the loaders, crucial in industries where time and efficiency are invaluable. Loader air filters, while small and sometimes overlooked, play an undeniable role in the productivity and efficiency of heavy machinery. Getting the right filter means fewer worries about unexpected breakdowns and more confidence in handling the demanding tasks characteristic of loader operations. Investing in a high-quality air filter is not just a maintenance step; it’s a commitment to excellence and sustainability in professional practices.

Additionally, trust in a brand or supplier is paramount. In a market where many options are available, choosing a supplier with a proven track record of reliability and quality can make all the difference. Read reviews and customer testimonials, and look for certifications that vouch for the product's credibility. A trustworthy supplier will often offer guidance and support, ensuring their products deliver optimal performance. In essence, the experience of many seasoned professionals reinforces the importance of not taking shortcuts with loader air filters. A correlation between consistent, top-notch performance, and regular maintenance includes investing time and perhaps more resources upfront to ensure you have the best components for your equipment. The long-term benefits not only reflect in savings on repairs and fuel costs but also in the extended life and reliability of the loaders, crucial in industries where time and efficiency are invaluable. Loader air filters, while small and sometimes overlooked, play an undeniable role in the productivity and efficiency of heavy machinery. Getting the right filter means fewer worries about unexpected breakdowns and more confidence in handling the demanding tasks characteristic of loader operations. Investing in a high-quality air filter is not just a maintenance step; it’s a commitment to excellence and sustainability in professional practices.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: