ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 19, 2025 08:11 Back to list

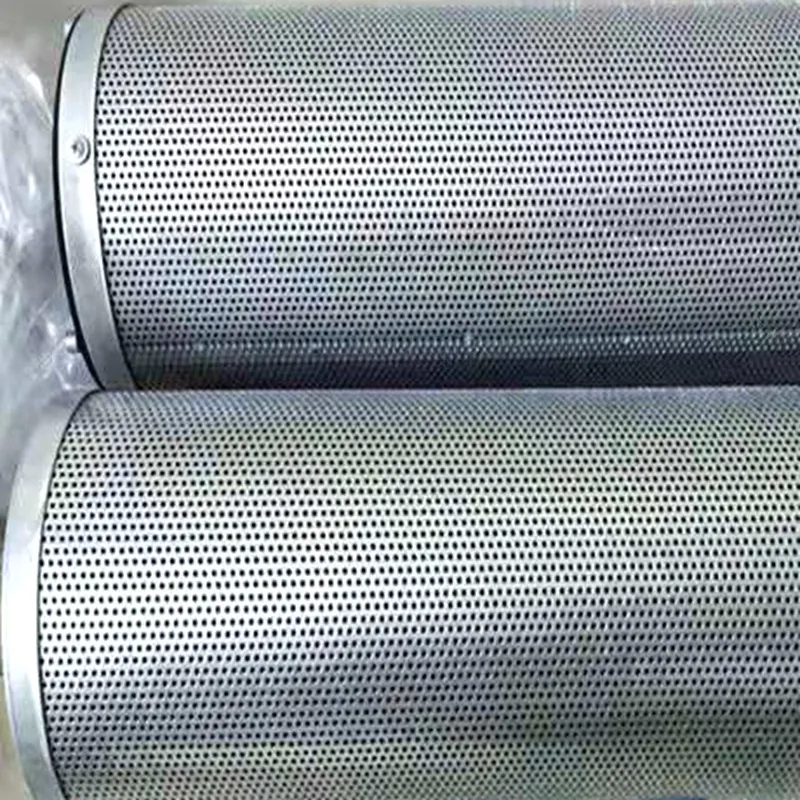

air filter for excavator

Excavators are widely recognized as the workhorses of the construction industry, playing a crucial role in diverse applications, from urban construction projects to large-scale mining operations. However, their efficiency and longevity greatly depend on the condition of their components, and excavator air filters stand out as one of the key elements requiring diligent attention.

Authoritative sources within the construction equipment industry underscore the importance of regular filter inspections and replacements. While the general guideline suggests replacing air filters every 500 operational hours, this can vary significantly based on environmental conditions. Trusted suppliers recommend a more frequent inspection routine, allowing operators to adjust maintenance schedules to match the actual wear and tear experienced by the equipment. This proactive approach not only maximizes the lifespan of the air filters but also ensures optimal engine performance. Trust in the quality and reliability of air filters is enhanced by selecting reputable brands known for their rigorous testing and adherence to industry standards. Brands that invest in high-grade materials and innovative designs often provide superior filtration performance, ensuring the excavator engine remains safeguarded even in the most challenging environments. Furthermore, engaging with supplier partners who offer technical support and guidance in selecting the appropriate filter type can further strengthen this trust, ensuring operators make informed decisions tailored to their operational needs. In conclusion, the role of air filters in an excavator's performance cannot be overstated. A well-maintained air filter system is crucial for minimizing operational disruptions and protecting the engine from potentially adverse conditions. For construction companies and equipment operators aiming to enhance performance, minimize fuel expenditure, and extend the life of their machinery, the selection and upkeep of air filters demand careful attention. By focusing on quality, appropriate selection, and regular maintenance, the challenges posed by demanding operational environments can be effectively countered, ensuring the excavator continues to perform at its peak efficiency.

Authoritative sources within the construction equipment industry underscore the importance of regular filter inspections and replacements. While the general guideline suggests replacing air filters every 500 operational hours, this can vary significantly based on environmental conditions. Trusted suppliers recommend a more frequent inspection routine, allowing operators to adjust maintenance schedules to match the actual wear and tear experienced by the equipment. This proactive approach not only maximizes the lifespan of the air filters but also ensures optimal engine performance. Trust in the quality and reliability of air filters is enhanced by selecting reputable brands known for their rigorous testing and adherence to industry standards. Brands that invest in high-grade materials and innovative designs often provide superior filtration performance, ensuring the excavator engine remains safeguarded even in the most challenging environments. Furthermore, engaging with supplier partners who offer technical support and guidance in selecting the appropriate filter type can further strengthen this trust, ensuring operators make informed decisions tailored to their operational needs. In conclusion, the role of air filters in an excavator's performance cannot be overstated. A well-maintained air filter system is crucial for minimizing operational disruptions and protecting the engine from potentially adverse conditions. For construction companies and equipment operators aiming to enhance performance, minimize fuel expenditure, and extend the life of their machinery, the selection and upkeep of air filters demand careful attention. By focusing on quality, appropriate selection, and regular maintenance, the challenges posed by demanding operational environments can be effectively countered, ensuring the excavator continues to perform at its peak efficiency.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: