ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 19, 2025 07:40 Back to list

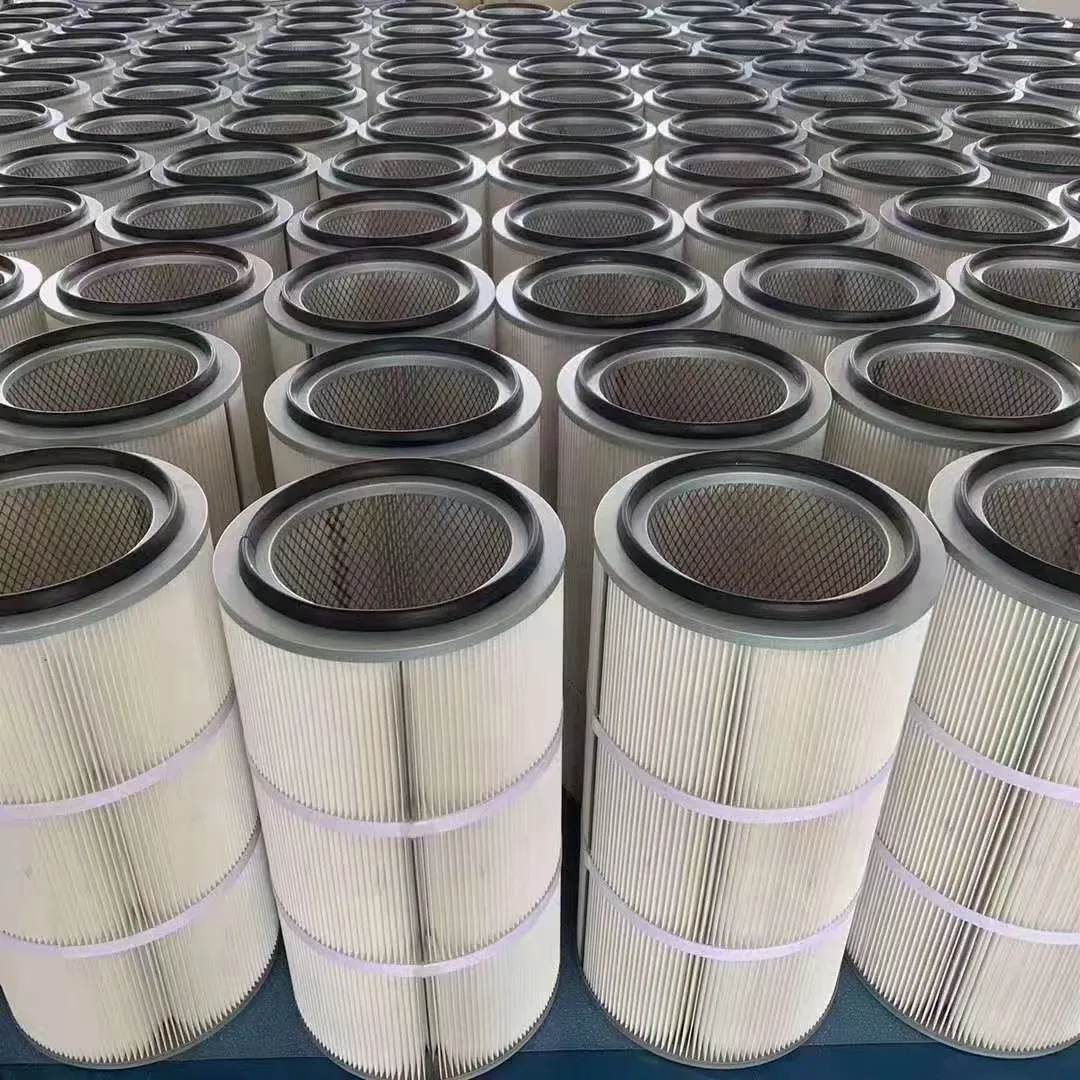

air filter for excavator

Excavator air filters play a pivotal role in maintaining the longevity and performance of your heavy machinery. Selecting the right air filter isn't just about keeping the engine safe from contaminants; it's about ensuring efficiency and cost-effectiveness in the long run. To put this into perspective, one must understand the significance, varieties, and maintenance practices involved in the realm of excavator air filters.

Educating operators on the nuances of air filter maintenance can bolster machine reliability and operational efficiency. Providing training continuously updates users on best practices, aligning with the evolving designs and technologies incorporated in modern heavy machinery. Moreover, consulting with an expert or an authorized dealer about the most fitting air filter for your specific excavator model offers peace of mind and validates every purchase decision. Trustworthiness in product quality arises from empirical data and user testimonials. Premium brands often invest in rigorous testing and third-party validation to stand by their claims of efficiency and longevity. Investment in such high-caliber air filters may come with upfront costs; however, they are justified by the savings on maintenance and enhanced engine performance over time. Ultimately, conquering the maintenance challenges posed by excavator air filters involves a blend of knowledge, practice, and product excellence. Through informed choices and rigorous upkeep, operators not only safeguard their machinery but also enhance the productivity and economic viability of their operations. Excavator air filters, albeit a small component, are indeed linchpins in the wheel of heavy-duty equipment management. By ensuring these practices are followed, companies reflect a commitment to quality and reliability, fostering a sense of authority and trust within their operational infrastructure. This, in turn, translates to enhanced client satisfaction, business growth, and a fortified reputation in the realm of heavy machinery operations.

Educating operators on the nuances of air filter maintenance can bolster machine reliability and operational efficiency. Providing training continuously updates users on best practices, aligning with the evolving designs and technologies incorporated in modern heavy machinery. Moreover, consulting with an expert or an authorized dealer about the most fitting air filter for your specific excavator model offers peace of mind and validates every purchase decision. Trustworthiness in product quality arises from empirical data and user testimonials. Premium brands often invest in rigorous testing and third-party validation to stand by their claims of efficiency and longevity. Investment in such high-caliber air filters may come with upfront costs; however, they are justified by the savings on maintenance and enhanced engine performance over time. Ultimately, conquering the maintenance challenges posed by excavator air filters involves a blend of knowledge, practice, and product excellence. Through informed choices and rigorous upkeep, operators not only safeguard their machinery but also enhance the productivity and economic viability of their operations. Excavator air filters, albeit a small component, are indeed linchpins in the wheel of heavy-duty equipment management. By ensuring these practices are followed, companies reflect a commitment to quality and reliability, fostering a sense of authority and trust within their operational infrastructure. This, in turn, translates to enhanced client satisfaction, business growth, and a fortified reputation in the realm of heavy machinery operations.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: