ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 16, 2025 07:21 Back to list

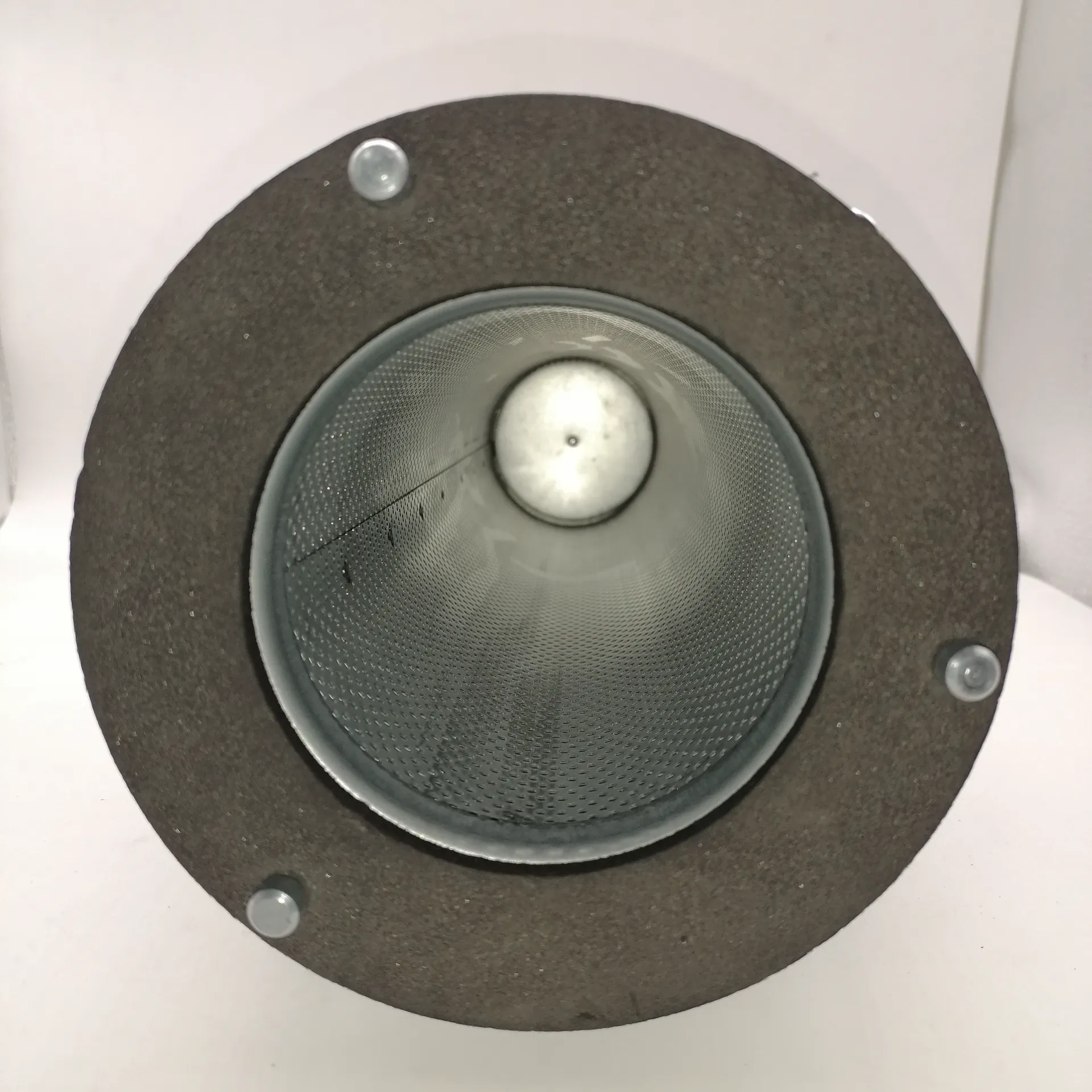

air filter for excavator

Choosing the right air filter for your excavator can significantly impact the performance and longevity of this heavy-duty equipment. Excavators, being an integral part of the construction industry, face extreme environmental conditions such as dust, debris, and other particulates. Therefore, understanding the nuances of selecting an appropriate air filter not only enhances the efficiency of the machine but also optimizes its operational costs and life-span.

The materials used in filter construction also play a vital role in efficiency. High-quality materials ensure durability and enhanced filtering capacity. Advances in technology have led to the development of synthetic air filters, which combine the benefits of both traditional and modern designs. These filters are engineered to provide superior filtration and longevity, making them suitable for the arduous demands placed on excavators. While selecting the appropriate filter it is essential to consider several factors the working environment, maintenance practices, and the manufacturer's recommendations. Heavy dust and particulate environments may necessitate more frequent filter changes or the use of a more robust filtering solution. It is advantageous to keep track of the operational hours and conditions to assess the need for filter maintenance or replacement. Regular maintenance and timely replacement of filters can prevent costly downtime and extend the operational life of the excavator. Furthermore, the reputation of the filter manufacturer also adds to the credibility of the filter choice. Trusted brands with established track records in producing reliable, high-quality filters are generally preferred. They often offer warranties or guarantees, reassuring users about product performance and reliability. Lastly, always rely on a professional to handle and replace air filters. Improper installation or handling can negate the benefits of even the highest quality filter. Training models or repair and maintenance personnel in filter management ensures that the equipment operates with optimal efficiency and safety. One cannot undervalue the role of a good air filter in maintaining the excavator's performance. By selecting the right filter, adhering to regular maintenance schedules, and choosing a reputable brand, the efficiency and lifespan of an excavator can be enhanced, saving time and money in the long run. As the construction industry continues to grow and evolve, integrating advanced filter technologies will be pivotal in meeting the demands for sustainability and efficiency.

The materials used in filter construction also play a vital role in efficiency. High-quality materials ensure durability and enhanced filtering capacity. Advances in technology have led to the development of synthetic air filters, which combine the benefits of both traditional and modern designs. These filters are engineered to provide superior filtration and longevity, making them suitable for the arduous demands placed on excavators. While selecting the appropriate filter it is essential to consider several factors the working environment, maintenance practices, and the manufacturer's recommendations. Heavy dust and particulate environments may necessitate more frequent filter changes or the use of a more robust filtering solution. It is advantageous to keep track of the operational hours and conditions to assess the need for filter maintenance or replacement. Regular maintenance and timely replacement of filters can prevent costly downtime and extend the operational life of the excavator. Furthermore, the reputation of the filter manufacturer also adds to the credibility of the filter choice. Trusted brands with established track records in producing reliable, high-quality filters are generally preferred. They often offer warranties or guarantees, reassuring users about product performance and reliability. Lastly, always rely on a professional to handle and replace air filters. Improper installation or handling can negate the benefits of even the highest quality filter. Training models or repair and maintenance personnel in filter management ensures that the equipment operates with optimal efficiency and safety. One cannot undervalue the role of a good air filter in maintaining the excavator's performance. By selecting the right filter, adhering to regular maintenance schedules, and choosing a reputable brand, the efficiency and lifespan of an excavator can be enhanced, saving time and money in the long run. As the construction industry continues to grow and evolve, integrating advanced filter technologies will be pivotal in meeting the demands for sustainability and efficiency.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: