ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 16, 2025 07:02 Back to list

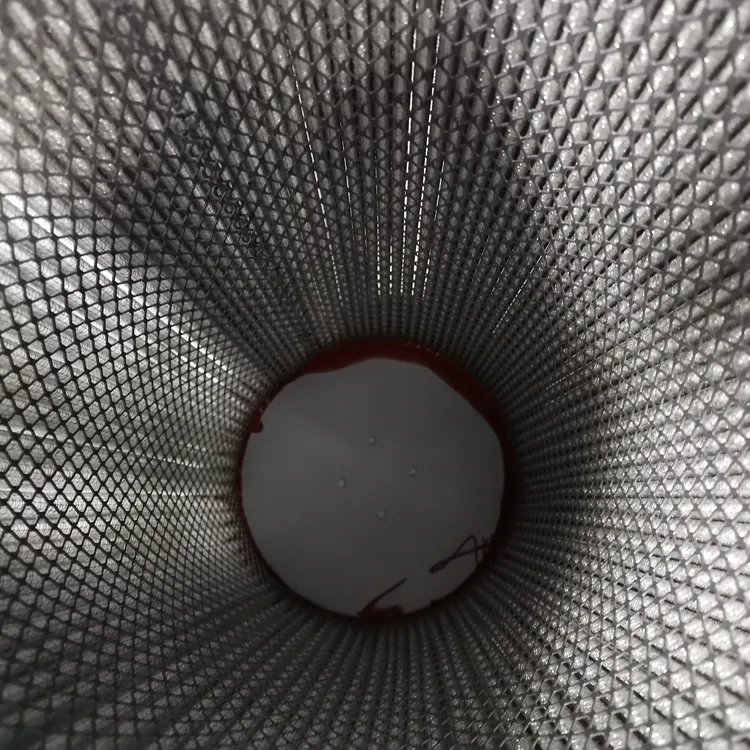

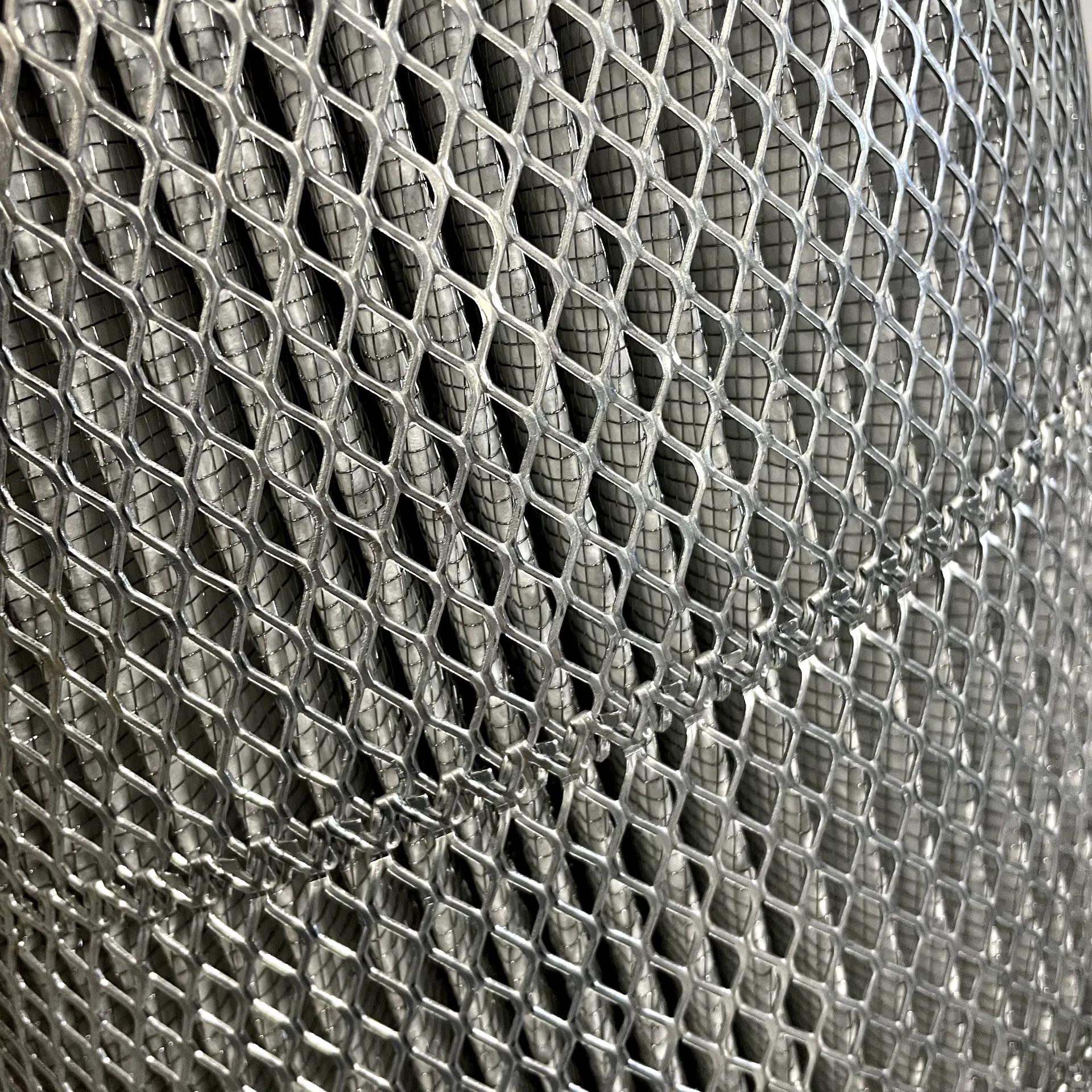

air filter for excavator

Choosing the right excavator air filter is crucial for the optimal performance of your machinery. Excavators operate in diverse conditions, from dusty construction sites to muddy terrains. The air filter plays a vital role in protecting the engine by filtering dust, debris, and contaminants that could otherwise cause serious damage and reduce efficiency.

In terms of authoritativeness, manufacturers like Caterpillar, John Deere, and Komatsu are recognized for producing reliable excavator air filters. They conduct extensive testing and quality assurance for their products, ensuring they meet industry standards and perform efficiently in severe conditions. Their reputation in the heavy machinery sector provides a layer of trust that many operators rely on. Trustworthiness also extends to the maintenance practices of replacing and cleaning air filters. Keeping a regular maintenance schedule is paramount. Operators should check filters for any blockages or damage, cleaning or replacing them every 250 hours of operation or as recommended by the manufacturer. Properly maintaining filters not only enhances the excavator’s efficiency but also prevents costly engine repairs, aligning with best practices observed by many industry professionals. In conclusion, investing in a high-quality excavator air filter supports the machine's performance, reduces maintenance costs, and prolongs engine life. Experienced operators consistently emphasize the value of using only reputable brands and following expert maintenance advice. Trustworthiness in this context is defined by the adherence to proven maintenance standards and reliance on authoritative sources for filter selection. Therefore, selecting the appropriate excavator air filter is not just about upfront costs but ensuring consistent operational efficiency and longevity of the equipment.

In terms of authoritativeness, manufacturers like Caterpillar, John Deere, and Komatsu are recognized for producing reliable excavator air filters. They conduct extensive testing and quality assurance for their products, ensuring they meet industry standards and perform efficiently in severe conditions. Their reputation in the heavy machinery sector provides a layer of trust that many operators rely on. Trustworthiness also extends to the maintenance practices of replacing and cleaning air filters. Keeping a regular maintenance schedule is paramount. Operators should check filters for any blockages or damage, cleaning or replacing them every 250 hours of operation or as recommended by the manufacturer. Properly maintaining filters not only enhances the excavator’s efficiency but also prevents costly engine repairs, aligning with best practices observed by many industry professionals. In conclusion, investing in a high-quality excavator air filter supports the machine's performance, reduces maintenance costs, and prolongs engine life. Experienced operators consistently emphasize the value of using only reputable brands and following expert maintenance advice. Trustworthiness in this context is defined by the adherence to proven maintenance standards and reliance on authoritative sources for filter selection. Therefore, selecting the appropriate excavator air filter is not just about upfront costs but ensuring consistent operational efficiency and longevity of the equipment.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: