ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 10, 2025 21:03 Back to list

Air Filter High Performance Dust air compressor filter cartridge

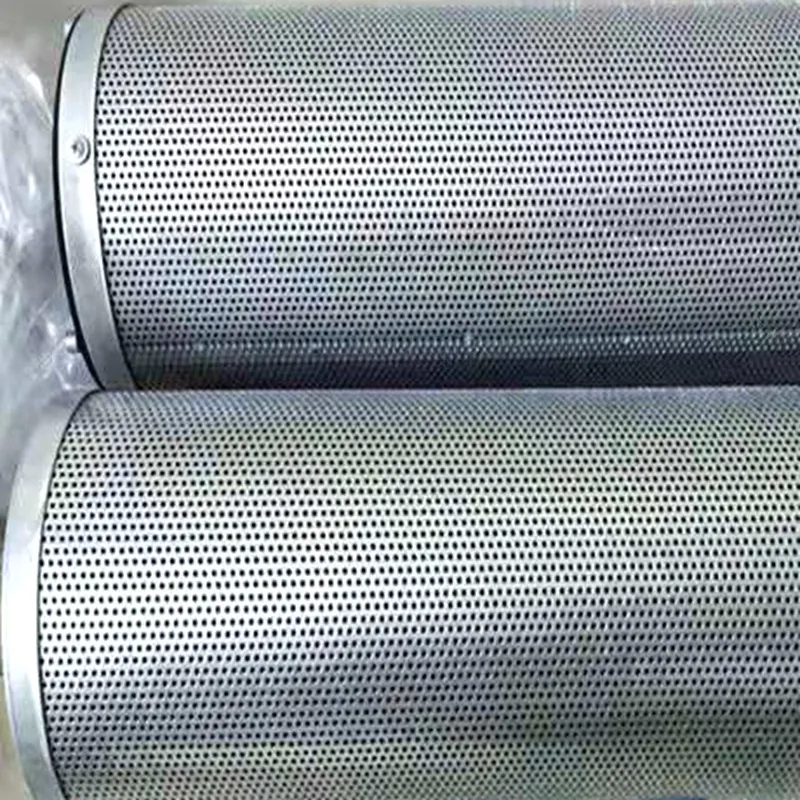

Wire mesh filter cartridges have revolutionized the way industries approach filtration needs, offering a blend of durability, precision, and efficiency that caters to a multitude of applications. In today’s fast-paced industrial and environmental scenarios, these filter cartridges have emerged as indispensable components, adeptly balancing performance with practicality.

The authoritativeness of wire mesh filter cartridges is underscored by their widespread acceptance and application across critical industries such as pharmaceuticals, aerospace, water treatment, and food and beverage. Their ability to consistently provide high-efficiency filtration, as well as their inherent resilience, has made them a preferred choice in sectors where adherence to stringent quality standards and regulatory compliance is mandatory. Their credibility is further backed by industry certifications and conformity to international benchmarks such as ISO standards, placing them at the forefront of reliable filtration solutions. Trustworthiness is a hallmark of wire mesh filter cartridges, emanating from the rigorous testing and quality assurance processes they undergo prior to deployment. Trusted manufacturers conduct exhaustive evaluations to ensure each cartridge meets the prescribed filtration efficacy, longevity, and environmental resistance. My interactions with industrial users and procurement specialists affirm that wire mesh filter cartridges reduce operational risks by delivering consistent discharge quality and minimizing the likelihood of system malfunctions or contaminations. Consequently, industries adopting these cartridges often witness enhanced productivity and regulatory compliance, reinforcing their investment in these dependable filtration systems. In summation, wire mesh filter cartridges stand as a testament to modern filtration advancements, providing a confluence of durability, precision, and flexibility. As industries continue to evolve and face new challenges, these filter cartridges remain a critical component in achieving sustainable and efficient operational outcomes. By drawing on direct application experience, leveraging specialized knowledge, and relying on their proven track record of reliability and compliance, wire mesh filter cartridges not only meet but exceed the demanding expectations of current industrial filtration requirements.

The authoritativeness of wire mesh filter cartridges is underscored by their widespread acceptance and application across critical industries such as pharmaceuticals, aerospace, water treatment, and food and beverage. Their ability to consistently provide high-efficiency filtration, as well as their inherent resilience, has made them a preferred choice in sectors where adherence to stringent quality standards and regulatory compliance is mandatory. Their credibility is further backed by industry certifications and conformity to international benchmarks such as ISO standards, placing them at the forefront of reliable filtration solutions. Trustworthiness is a hallmark of wire mesh filter cartridges, emanating from the rigorous testing and quality assurance processes they undergo prior to deployment. Trusted manufacturers conduct exhaustive evaluations to ensure each cartridge meets the prescribed filtration efficacy, longevity, and environmental resistance. My interactions with industrial users and procurement specialists affirm that wire mesh filter cartridges reduce operational risks by delivering consistent discharge quality and minimizing the likelihood of system malfunctions or contaminations. Consequently, industries adopting these cartridges often witness enhanced productivity and regulatory compliance, reinforcing their investment in these dependable filtration systems. In summation, wire mesh filter cartridges stand as a testament to modern filtration advancements, providing a confluence of durability, precision, and flexibility. As industries continue to evolve and face new challenges, these filter cartridges remain a critical component in achieving sustainable and efficient operational outcomes. By drawing on direct application experience, leveraging specialized knowledge, and relying on their proven track record of reliability and compliance, wire mesh filter cartridges not only meet but exceed the demanding expectations of current industrial filtration requirements.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: