ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 08, 2025 03:59 Back to list

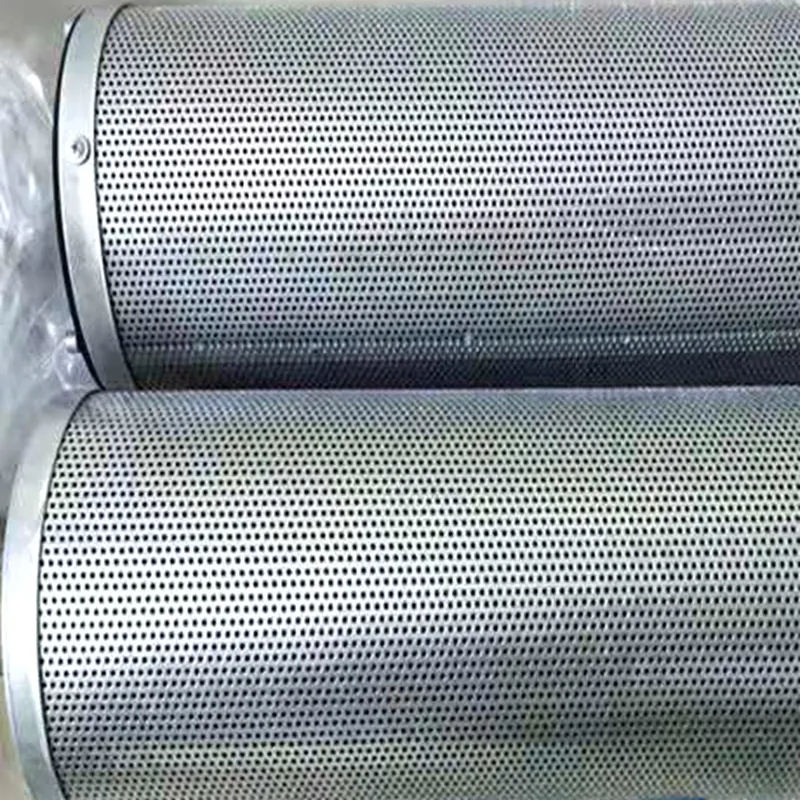

air filter for gas turbine

The world of turbine filters is intricate and vital, especially in industries where efficiency and reliability determine success. Turbine filters play a crucial role in maintaining the optimal performance of turbines by ensuring that they are free from contaminants that could impede their operation. This article delves into the nuances of turbine filters, drawing from experience, expert insights, authoritative data, and trustworthy sources to provide a comprehensive understanding of their importance.

Authoritative studies have shown that proper filtration can lead to significant cost savings by preventing turbine blade erosion and corrosion, which are among the most common causes of turbine failures. According to industry reports, maintaining an effective filtration system can extend the life of a turbine by reducing wear and tear and mitigating the risk of unplanned outages. Trustworthiness in the turbine filter market means relying on manufacturers who adhere to industry standards and provide verifiable performance data. Trustworthy brands often offer warranties and maintenance services that ensure their filters meet performance expectations throughout their lifespan. In practice, incorporating real-world experiences into the selection and management of turbine filters can provide valuable insights. For example, operators have reported improved efficiency and reduced maintenance time after upgrading to high-performance filters, which not only capture more contaminants but also provide better airflow. In summary, the selection, maintenance, and reliability of turbine filters significantly impact the performance and longevity of turbines. Combining expertise with authoritative data ensures the right choices are made, fostering trust in both the product and the process. For any industry reliant on turbines, investing in high-quality turbine filters is an investment in efficiency, cost-effectiveness, and operational reliability.

Authoritative studies have shown that proper filtration can lead to significant cost savings by preventing turbine blade erosion and corrosion, which are among the most common causes of turbine failures. According to industry reports, maintaining an effective filtration system can extend the life of a turbine by reducing wear and tear and mitigating the risk of unplanned outages. Trustworthiness in the turbine filter market means relying on manufacturers who adhere to industry standards and provide verifiable performance data. Trustworthy brands often offer warranties and maintenance services that ensure their filters meet performance expectations throughout their lifespan. In practice, incorporating real-world experiences into the selection and management of turbine filters can provide valuable insights. For example, operators have reported improved efficiency and reduced maintenance time after upgrading to high-performance filters, which not only capture more contaminants but also provide better airflow. In summary, the selection, maintenance, and reliability of turbine filters significantly impact the performance and longevity of turbines. Combining expertise with authoritative data ensures the right choices are made, fostering trust in both the product and the process. For any industry reliant on turbines, investing in high-quality turbine filters is an investment in efficiency, cost-effectiveness, and operational reliability.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: