ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

3 月 . 05, 2025 04:29 Back to list

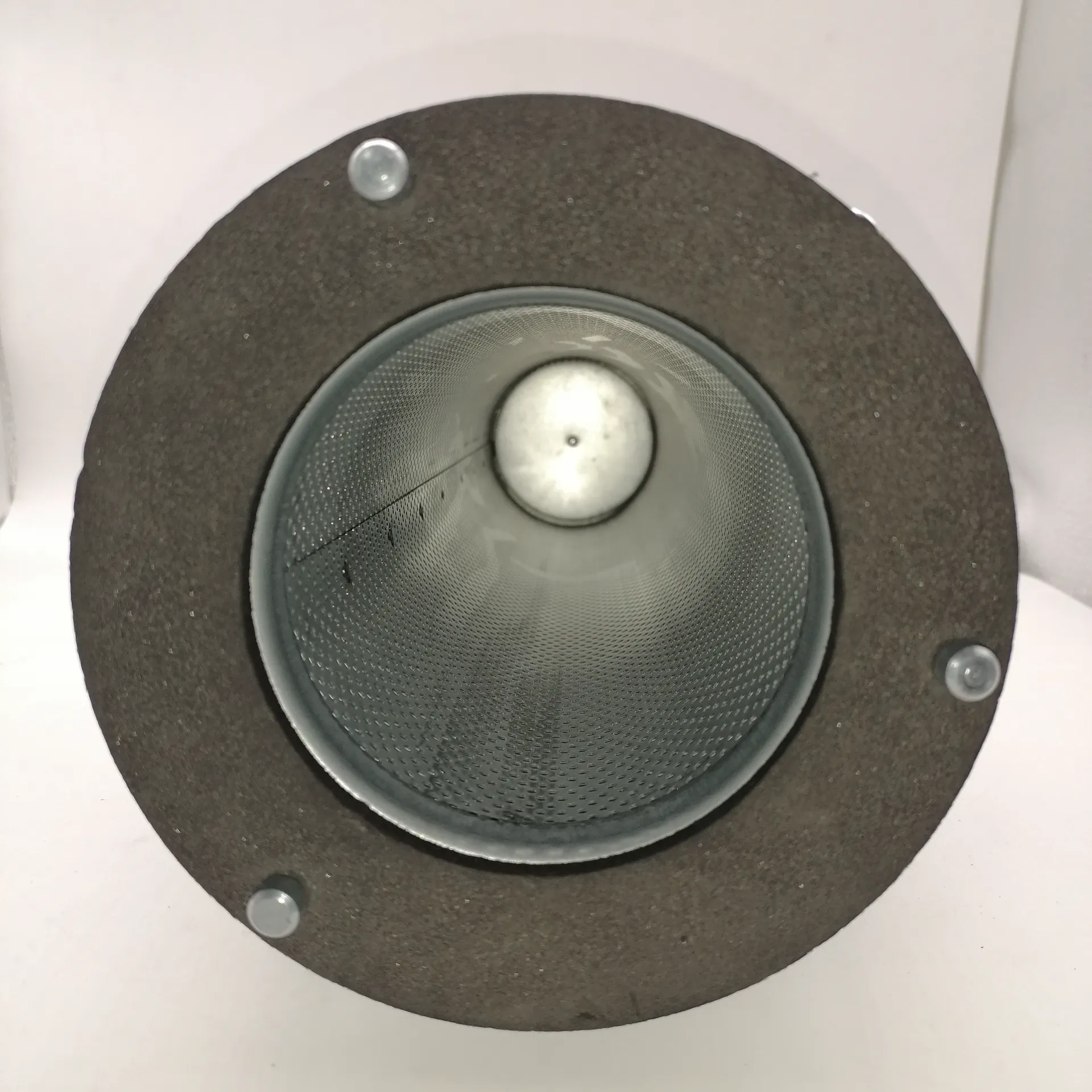

gas turbine air intake filter

Turbine air intake filters play an essential role in ensuring the optimal performance and longevity of gas turbines used in various industries. The importance of high-quality filters cannot be emphasized enough, especially given the critical nature of turbine operations in power generation, aviation, and other applications. These filters are designed to protect the turbine components from harmful particles, moisture, and other contaminants that could otherwise lead to wear and tear or even significant damage.

Expertise in conducting airflow analyses is integral in the design and selection of air intake filters. Advanced computational fluid dynamics (CFD) modeling allows engineers to simulate airflow through filters and predict performance under various environmental conditions. Such analyses contribute to the development of tailored filtration solutions that enhance airflow management and improve the overall energy efficiency of the turbine systems. The advancement of smart technology in filtration systems is progressively transforming industrial standards. Next-generation turbine air intake filters incorporate IoT sensors that provide real-time data on air quality, pressure differentials, and filter status. This data is essential for predictive maintenance, allowing operators to pre-emptively address potential issues before they escalate into operational disruptions. The integration of smart systems underpins the reliability and longevity of turbine operations, ultimately reinforcing trust in advanced filtration solutions. The credibility of turbine air intake filter manufacturers is often measured by their adherence to industry standards and certifications, including ISO 9001 and other relevant standards that benchmark quality and performance. Reputable manufacturers invest in rigorous product testing and continuous innovation to ensure their filters meet the diverse needs of global markets. Collaboration with industry leaders, ongoing research, and the development of proprietary technologies establish a foundation of trust and reinforce the authority of these manufacturers in the competitive landscape. In conclusion, turbine air intake filters are indispensable to maintaining robust and efficient turbine operations. By selecting the right filters and implementing comprehensive maintenance strategies, industries can enhance performance, reduce operational costs, and extend the lifespan of their valuable turbine assets. The continuous evolution in filter technology and the integration of smart systems mark a promising direction for mitigating risks and maximizing the return on investment in turbine systems.

Expertise in conducting airflow analyses is integral in the design and selection of air intake filters. Advanced computational fluid dynamics (CFD) modeling allows engineers to simulate airflow through filters and predict performance under various environmental conditions. Such analyses contribute to the development of tailored filtration solutions that enhance airflow management and improve the overall energy efficiency of the turbine systems. The advancement of smart technology in filtration systems is progressively transforming industrial standards. Next-generation turbine air intake filters incorporate IoT sensors that provide real-time data on air quality, pressure differentials, and filter status. This data is essential for predictive maintenance, allowing operators to pre-emptively address potential issues before they escalate into operational disruptions. The integration of smart systems underpins the reliability and longevity of turbine operations, ultimately reinforcing trust in advanced filtration solutions. The credibility of turbine air intake filter manufacturers is often measured by their adherence to industry standards and certifications, including ISO 9001 and other relevant standards that benchmark quality and performance. Reputable manufacturers invest in rigorous product testing and continuous innovation to ensure their filters meet the diverse needs of global markets. Collaboration with industry leaders, ongoing research, and the development of proprietary technologies establish a foundation of trust and reinforce the authority of these manufacturers in the competitive landscape. In conclusion, turbine air intake filters are indispensable to maintaining robust and efficient turbine operations. By selecting the right filters and implementing comprehensive maintenance strategies, industries can enhance performance, reduce operational costs, and extend the lifespan of their valuable turbine assets. The continuous evolution in filter technology and the integration of smart systems mark a promising direction for mitigating risks and maximizing the return on investment in turbine systems.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: