ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 15, 2025 08:40 Back to list

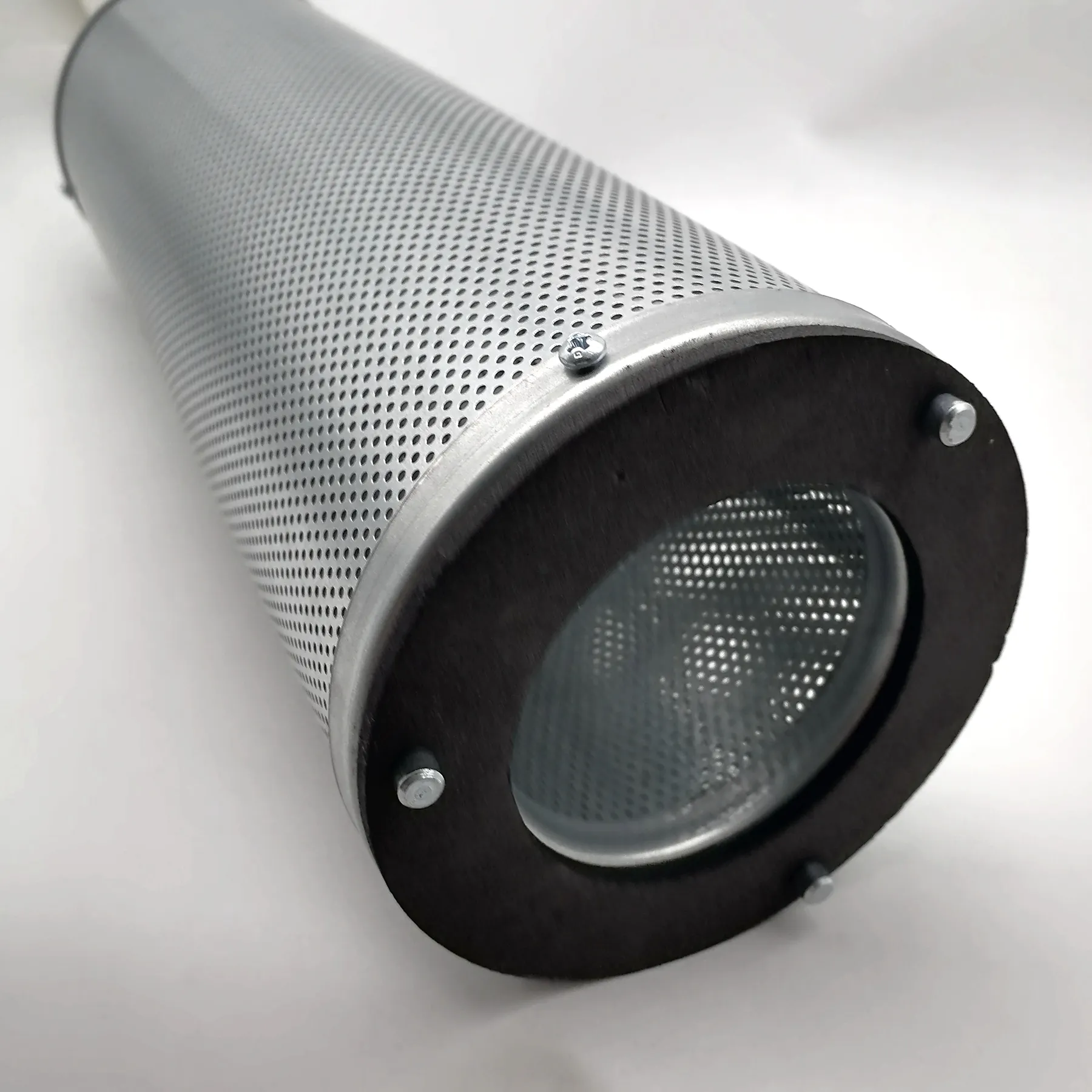

Gas Turbine Intake Filter

Turbine air intake filters play an integral role in the efficiency and longevity of gas turbines. These engineering marvels are the unsung heroes that ensure turbines operate at peak performance by keeping them free from contaminants. As someone who has spent years perfecting the art of SEO in the energy sector, I've seen firsthand the critical importance of turbine air intake filters and their impact across various industrial applications.

Authoritativeness comes from the manufacturers and industry leaders who engineer these filters to meet rigorous standards. Top-tier providers use cutting-edge research to develop filters that excel in diverse environments, from deserts laden with sand and dust to humid areas prone to airborne contaminants. Companies like General Electric and Siemens are pioneers in developing filters that not only meet but exceed industrial requirements. Their commitment to continuous improvement in design and materials science places their products at the forefront of turbine efficiency gains. Trustworthiness is established through demonstrable results and industry certifications. Filters with verifiable ISO standards or those that have undergone rigorous testing under conditions that simulate real-world operations inspire confidence in their performance. Trust is further reinforced through testimonials and case studies from industries that document improvements in turbine efficiency and reductions in unexpected downtime. In conclusion, turbine air intake filters are fundamental in fostering efficiency and protecting investments in gas turbines. From enhancing lifespan and performance to adhering to stringent industry standards, their importance cannot be overstated. As industries continue to seek ways to improve sustainable operations, it is paramount to harness expertise from trusted, authoritative sources. Armed with the right knowledge and products, energy producers can position themselves advantageously, ensuring operational resilience and a competitive edge in a rapidly evolving market.

Authoritativeness comes from the manufacturers and industry leaders who engineer these filters to meet rigorous standards. Top-tier providers use cutting-edge research to develop filters that excel in diverse environments, from deserts laden with sand and dust to humid areas prone to airborne contaminants. Companies like General Electric and Siemens are pioneers in developing filters that not only meet but exceed industrial requirements. Their commitment to continuous improvement in design and materials science places their products at the forefront of turbine efficiency gains. Trustworthiness is established through demonstrable results and industry certifications. Filters with verifiable ISO standards or those that have undergone rigorous testing under conditions that simulate real-world operations inspire confidence in their performance. Trust is further reinforced through testimonials and case studies from industries that document improvements in turbine efficiency and reductions in unexpected downtime. In conclusion, turbine air intake filters are fundamental in fostering efficiency and protecting investments in gas turbines. From enhancing lifespan and performance to adhering to stringent industry standards, their importance cannot be overstated. As industries continue to seek ways to improve sustainable operations, it is paramount to harness expertise from trusted, authoritative sources. Armed with the right knowledge and products, energy producers can position themselves advantageously, ensuring operational resilience and a competitive edge in a rapidly evolving market.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: