ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 08, 2025 06:40 Back to list

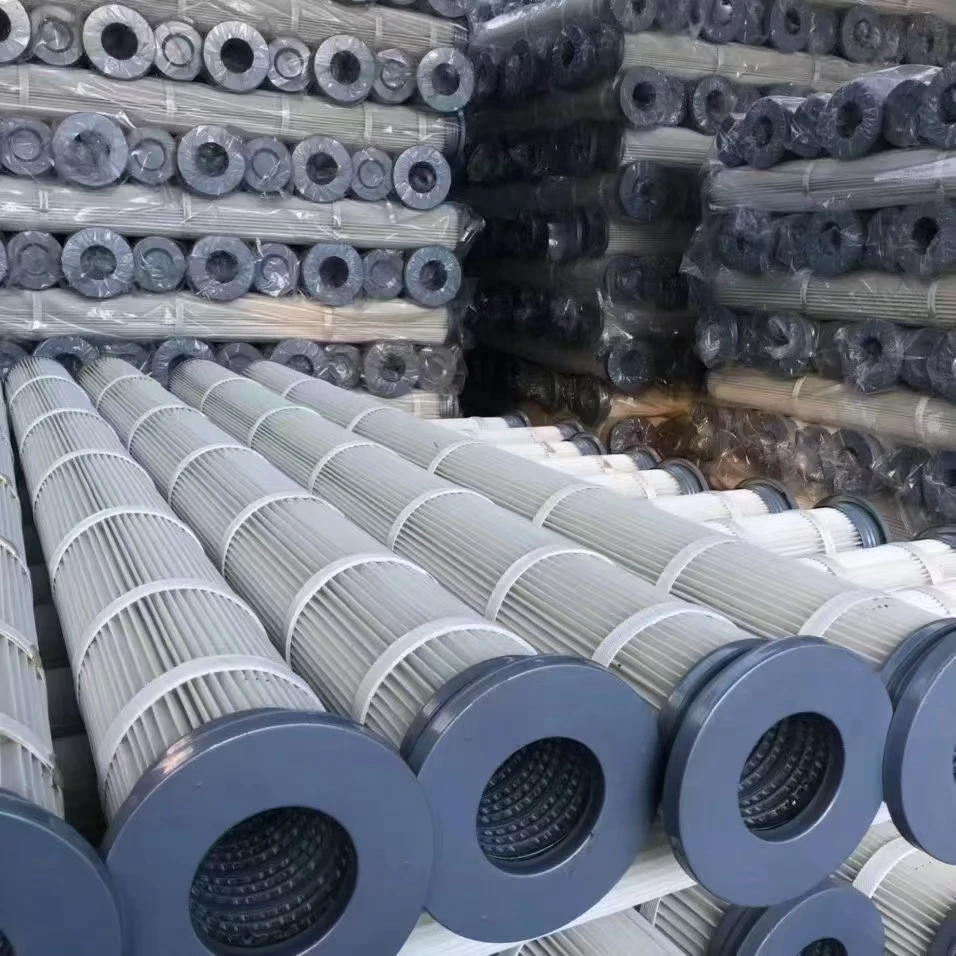

High performance industrial activated carbon filter cartridge

The stainless steel filter element is an essential component in various industrial and domestic applications, revered for its durability, efficiency, and cost-effectiveness. This article delves into the deeper intricacies of stainless steel filter elements, exploring their applications, advantages, and the unrivaled quality they bring to filtration processes.

Stainless steel filter elements are also recognized for their authoritative presence in regulatory compliance. Many industries are subject to strict standards regarding filtration and sanitation. Stainless steel filter elements are often engineered to meet or exceed these standards, making them a trustworthy choice for businesses aiming to comply with health, safety, and environmental regulations. Their use is a testament to a company's commitment to operational excellence and quality assurance. Trust is a crucial element in any industrial operation, and the reliability of stainless steel filter elements helps build that trust. These elements are designed to perform consistently over time, providing a stable and predictable flow of filtered material, which is essential for maintaining systems that require uninterrupted operation. This reliability translates into higher customer satisfaction and confidence in the products delivered or processes utilized. The investment in stainless steel filter elements is a step towards enhanced efficiency, reduced operational costs, and adherence to stringent regulations. Their long service life and ability to be tailored to specific needs make them a preferred choice across a range of industries. As more businesses lean towards sustainable and reliable solutions, stainless steel filter elements emerge as a beacon of innovation and durability, paving the way for future developments in filtration technology. In conclusion, stainless steel filter elements are more than just a filtration medium; they represent a confluence of innovation, reliability, and sustainability. By integrating these components into their systems, industries not only enhance their filtration capability but also contribute positively to environmental preservation and economic efficiency. Engaging with knowledgeable providers ensures that businesses can leverage the full potential of stainless steel filter elements, securing a competitive edge in today's demanding markets.

Stainless steel filter elements are also recognized for their authoritative presence in regulatory compliance. Many industries are subject to strict standards regarding filtration and sanitation. Stainless steel filter elements are often engineered to meet or exceed these standards, making them a trustworthy choice for businesses aiming to comply with health, safety, and environmental regulations. Their use is a testament to a company's commitment to operational excellence and quality assurance. Trust is a crucial element in any industrial operation, and the reliability of stainless steel filter elements helps build that trust. These elements are designed to perform consistently over time, providing a stable and predictable flow of filtered material, which is essential for maintaining systems that require uninterrupted operation. This reliability translates into higher customer satisfaction and confidence in the products delivered or processes utilized. The investment in stainless steel filter elements is a step towards enhanced efficiency, reduced operational costs, and adherence to stringent regulations. Their long service life and ability to be tailored to specific needs make them a preferred choice across a range of industries. As more businesses lean towards sustainable and reliable solutions, stainless steel filter elements emerge as a beacon of innovation and durability, paving the way for future developments in filtration technology. In conclusion, stainless steel filter elements are more than just a filtration medium; they represent a confluence of innovation, reliability, and sustainability. By integrating these components into their systems, industries not only enhance their filtration capability but also contribute positively to environmental preservation and economic efficiency. Engaging with knowledgeable providers ensures that businesses can leverage the full potential of stainless steel filter elements, securing a competitive edge in today's demanding markets.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: