ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 01, 2025 02:55 Back to list

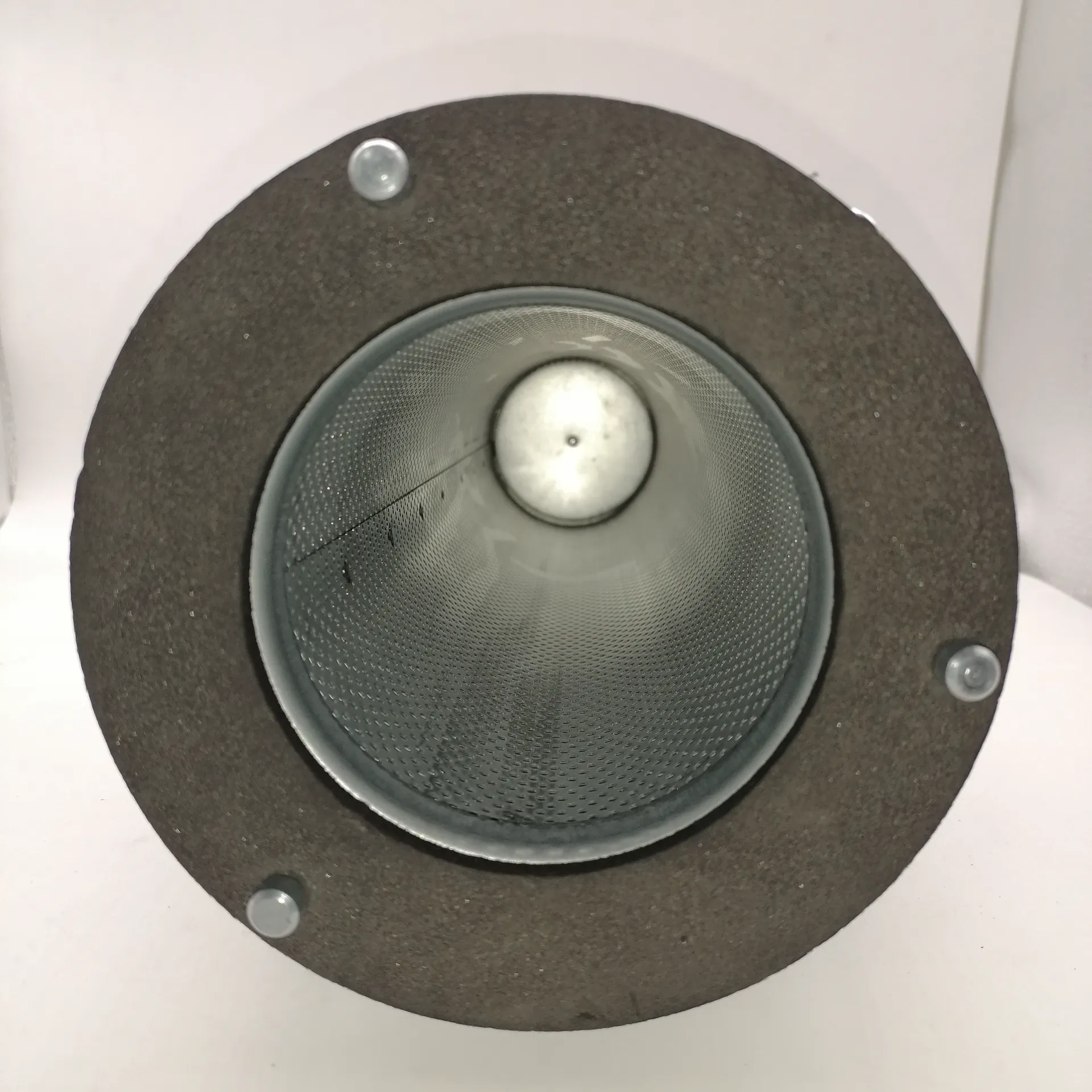

air compressor filter cartridge

Stainless steel cartridges have emerged as a game-changer in various industries due to their durability, efficiency, and long-term cost-effectiveness. These cartridges, known for their impeccable resistance to corrosion and heat, are widely employed in sectors ranging from water filtration to inkjet printing.

Safety is another critical factor where stainless steel cartridges shine. In industries like food processing or pharmaceuticals, where contamination can have severe consequences, the non-porous surface of stainless steel ensures that no harmful bacteria or residues linger post-cleaning. Authoritative bodies often mention stainless steel in their recommendations for best practices in hygiene and safety standards, making it a trusted choice for health-conscious industries. From an engineering perspective, the strength and structural integrity of stainless steel can withstand high pressure and temperatures without deforming. Engineers and technical experts consistently choose stainless steel cartridges for high-demand applications where lesser materials would fail. This attribute not only secures the longevity of the equipment but also ensures the safety of operations. Beyond its practical advantages, the aesthetic appeal of stainless steel remains unmatched. Its sleek, modern appearance can be a selling point, particularly in consumer-facing products such as high-end coffee machines or state-of-the-art printers. This versatility in application is backed by design experts who acknowledge the dual benefit of functionality and style. In conclusion, the switch to stainless steel cartridges is not just a trend but a strategic decision backed by empirical evidence. It embodies a commitment to quality, sustainability, and performance, addressing critical considerations for any business focused on long-term success. With a proven track record and endorsement from industry experts, stainless steel cartridges offer a compelling case for their widespread adoption, eventually setting a new standard in manufacturing and technology.

Safety is another critical factor where stainless steel cartridges shine. In industries like food processing or pharmaceuticals, where contamination can have severe consequences, the non-porous surface of stainless steel ensures that no harmful bacteria or residues linger post-cleaning. Authoritative bodies often mention stainless steel in their recommendations for best practices in hygiene and safety standards, making it a trusted choice for health-conscious industries. From an engineering perspective, the strength and structural integrity of stainless steel can withstand high pressure and temperatures without deforming. Engineers and technical experts consistently choose stainless steel cartridges for high-demand applications where lesser materials would fail. This attribute not only secures the longevity of the equipment but also ensures the safety of operations. Beyond its practical advantages, the aesthetic appeal of stainless steel remains unmatched. Its sleek, modern appearance can be a selling point, particularly in consumer-facing products such as high-end coffee machines or state-of-the-art printers. This versatility in application is backed by design experts who acknowledge the dual benefit of functionality and style. In conclusion, the switch to stainless steel cartridges is not just a trend but a strategic decision backed by empirical evidence. It embodies a commitment to quality, sustainability, and performance, addressing critical considerations for any business focused on long-term success. With a proven track record and endorsement from industry experts, stainless steel cartridges offer a compelling case for their widespread adoption, eventually setting a new standard in manufacturing and technology.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: