ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

3 月 . 06, 2025 15:21 Back to list

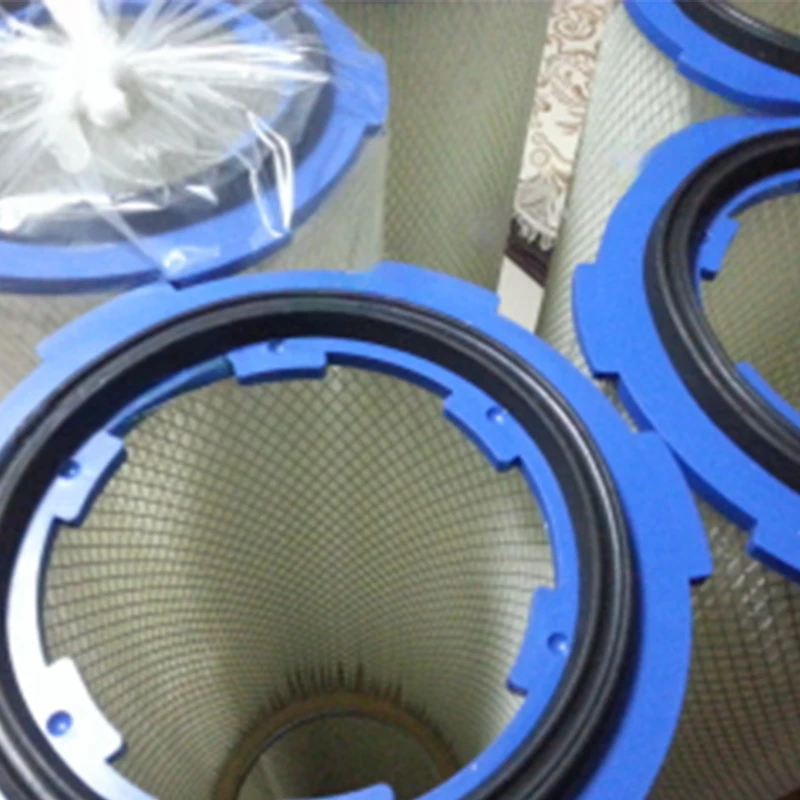

Air Filter High Performance Dust air compressor filter cartridge

The advent of advanced filtration technologies has revolutionized how industries manage particulate contamination in various processes. Among the numerous options available, stainless steel sintered filter cartridges stand out for their robustness and versatility. These components are not just a mere accessory but an intricate facet of numerous sectors, including chemical processing, food and beverage production, pharmaceuticals, and environmental management, where they are instrumental in ensuring product purity and process efficiency.

Authoritative industry standards and certifications lend credibility to stainless steel sintered filter cartridges, reinforcing their trustworthiness and increasing their adoption across various sectors. These cartridges conform to stringent quality and safety regulations, providing clients with peace of mind and assurance of their reliability. Partners and suppliers with a proven track record of quality manufacturing processes further bolster this assurance, making these cartridges a staple in high-stakes environments where failure is not an option. From a sustainability perspective, stainless steel sintered filter cartridges align well with modern ecological goals. Their reusability and long lifecycle mean reduced waste and lower environmental impacts compared to disposable filtration options. Furthermore, the robust nature of stainless steel allows for recycling at the end of its service life, contributing to circular economy initiatives embraced by environmentally-conscious companies. Real-world experiences echo the purported benefits of these filters. Industry professionals often share success stories demonstrating how switching to stainless steel sintered filter cartridges enhanced process efficiency, lowered long-term operational costs, and minimized downtime. These testimonials serve as valuable insights for companies contemplating an upgrade in their filtration systems. In summary, the integration of stainless steel sintered filter cartridges into industrial processes exemplifies a commitment to quality, durability, and efficiency. Their superior performance in challenging environments, combined with economic and environmental advantages, makes them an optimal choice for modern filtration needs. With a focus on experience, expertise, authoritativeness, and trustworthiness, adopting these filter solutions can catalyze enhanced productivity and sustainability achievements.

Authoritative industry standards and certifications lend credibility to stainless steel sintered filter cartridges, reinforcing their trustworthiness and increasing their adoption across various sectors. These cartridges conform to stringent quality and safety regulations, providing clients with peace of mind and assurance of their reliability. Partners and suppliers with a proven track record of quality manufacturing processes further bolster this assurance, making these cartridges a staple in high-stakes environments where failure is not an option. From a sustainability perspective, stainless steel sintered filter cartridges align well with modern ecological goals. Their reusability and long lifecycle mean reduced waste and lower environmental impacts compared to disposable filtration options. Furthermore, the robust nature of stainless steel allows for recycling at the end of its service life, contributing to circular economy initiatives embraced by environmentally-conscious companies. Real-world experiences echo the purported benefits of these filters. Industry professionals often share success stories demonstrating how switching to stainless steel sintered filter cartridges enhanced process efficiency, lowered long-term operational costs, and minimized downtime. These testimonials serve as valuable insights for companies contemplating an upgrade in their filtration systems. In summary, the integration of stainless steel sintered filter cartridges into industrial processes exemplifies a commitment to quality, durability, and efficiency. Their superior performance in challenging environments, combined with economic and environmental advantages, makes them an optimal choice for modern filtration needs. With a focus on experience, expertise, authoritativeness, and trustworthiness, adopting these filter solutions can catalyze enhanced productivity and sustainability achievements.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: