ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 17, 2025 23:49 Back to list

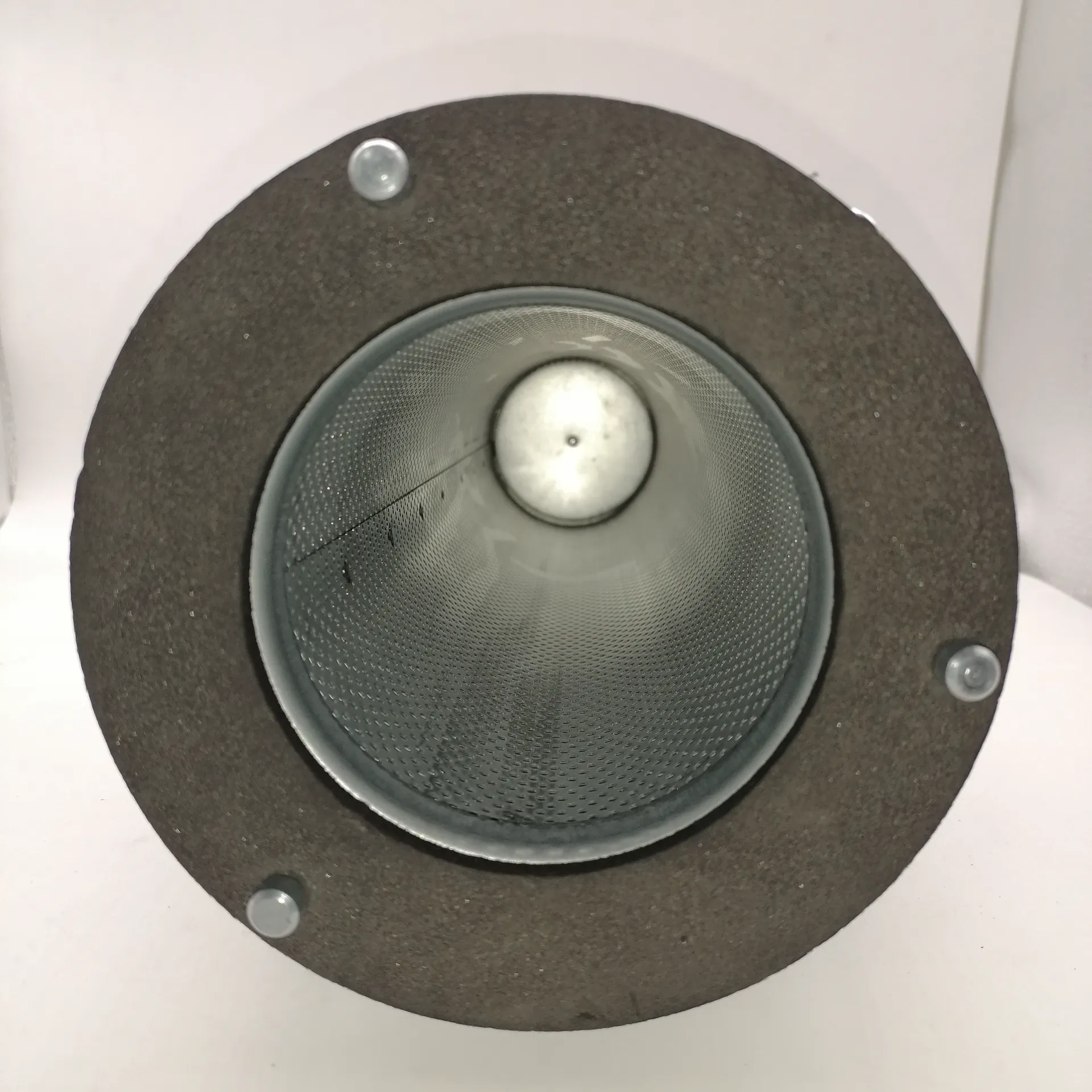

High efficiency coated polyester filter cartridge

In an industrial landscape where efficiency, precision, and reliability reign supreme, the SS pleated filter cartridge emerges as a quintessential component. This filtration device, crafted from stainless steel, stands as a beacon of innovation and functionality, offering substantial benefits across various sectors. It is vital to grasp the importance of this equipment, backed by genuine experience, technical proficiency, authoritative insight, and a trust-inspiring track record.

Authoritativeness is further established by industry standards and compliance certifications. The manufacturing processes for SS pleated filter cartridges often adhere to stringent international standards, such as ISO 9001 and FDA guidelines, among others. These certifications are not merely badges of honor but are testimonies to the cartridge's reliability and safety. They assure stakeholders that these products are manufactured following procedures that prioritize consumer safety and environmental responsibility. Trustworthiness is a cornerstone in selecting the right filtration system. Manufacturers of SS pleated filter cartridges who have harnessed decades of experience provide not only the product but also a legacy of innovation and customer satisfaction. User reviews and case studies reveal a consistent track record of problem-solving and value addition, fostering a sense of trust that is paramount in long-term industrial partnerships. Clients are not merely purchasing a product; they are investing in a brand promise that champions efficiency, safety, and advanced engineering. In conclusion, the SS pleated filter cartridge represents an intersection of practical design and cutting-edge technology, essential for any industry seeking to optimize its filtration processes. Its proven durability, backed by technical expertise, compliant manufacturing, and a history of reliable performance, solidifies its status as a leading choice. By integrating SS pleated filter cartridges into their systems, industries are poised to experience improved operational efficacy and product quality, establishing a foundation for future growth and innovation.

Authoritativeness is further established by industry standards and compliance certifications. The manufacturing processes for SS pleated filter cartridges often adhere to stringent international standards, such as ISO 9001 and FDA guidelines, among others. These certifications are not merely badges of honor but are testimonies to the cartridge's reliability and safety. They assure stakeholders that these products are manufactured following procedures that prioritize consumer safety and environmental responsibility. Trustworthiness is a cornerstone in selecting the right filtration system. Manufacturers of SS pleated filter cartridges who have harnessed decades of experience provide not only the product but also a legacy of innovation and customer satisfaction. User reviews and case studies reveal a consistent track record of problem-solving and value addition, fostering a sense of trust that is paramount in long-term industrial partnerships. Clients are not merely purchasing a product; they are investing in a brand promise that champions efficiency, safety, and advanced engineering. In conclusion, the SS pleated filter cartridge represents an intersection of practical design and cutting-edge technology, essential for any industry seeking to optimize its filtration processes. Its proven durability, backed by technical expertise, compliant manufacturing, and a history of reliable performance, solidifies its status as a leading choice. By integrating SS pleated filter cartridges into their systems, industries are poised to experience improved operational efficacy and product quality, establishing a foundation for future growth and innovation.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: