ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 15, 2025 11:10 Back to list

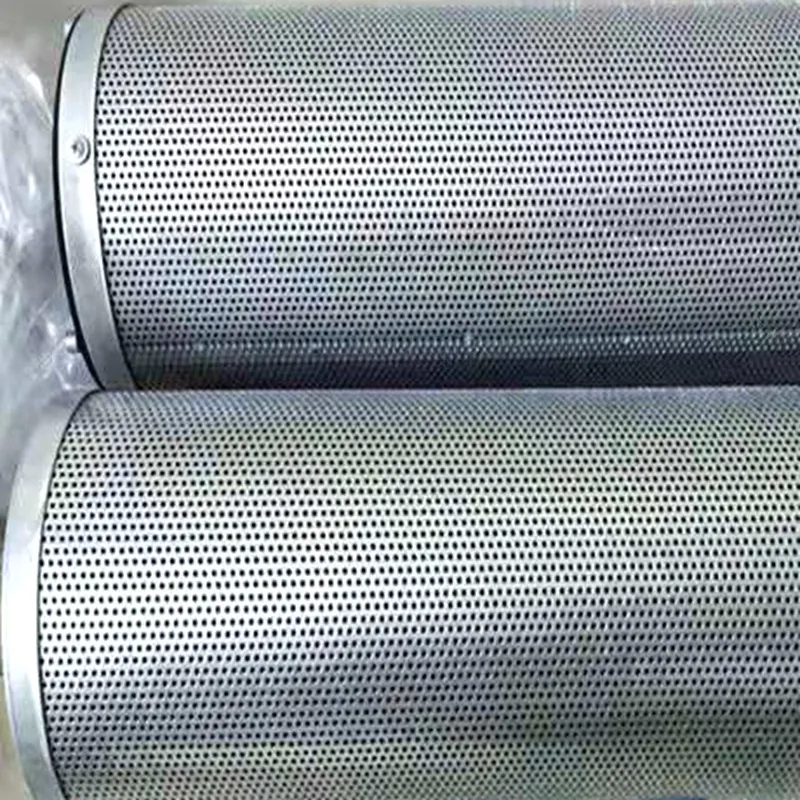

sintered ss filter cartridges

Sintered stainless steel filter cartridges are a cutting-edge solution in the realm of filtration technology. Known for their durability and high performance, these cartridges are used across a range of industries, including chemical processing, food and beverage, pharmaceuticals, and oil and gas. Their innovative design is not only highly efficient but also environmentally friendly, making them an ideal choice for companies committed to sustainability.

From an engineering perspective, one of the primary benefits of using these cartridges is their versatility. They are compatible with a wide range of systems and can be integrated into existing infrastructures without requiring significant modifications. Furthermore, the robustness of stainless steel ensures that the filters do not easily degrade, even under continuous use in harsh environments. This translates to considerable cost savings over time, as there is less need for frequent replacements or repairs. Sintered stainless steel filter cartridges also set industry benchmarks in terms of low-pressure drops during operation. This feature is particularly significant in processes where maintaining a constant flow is paramount. Lower pressure drops lead to increased energy efficiency, reducing the overall carbon footprint of the system. This aligns well with global efforts to improve energy efficiency standards and reduce environmental impacts. Trust in the performance of sintered stainless steel filter cartridges is backed by decades of research and development. Leading manufacturers conduct rigorous testing and quality control checks to ensure that every cartridge delivers optimal performance. Accredited certifications and compliance with international standards provide customers with peace of mind, knowing that they are investing in reliable and secure filtration systems. To conclude, sintered stainless steel filter cartridges represent the pinnacle of filtration technology. Their application across various industries is a testament to their superior quality, sustainability, and efficiency. As businesses continue to seek solutions that combine functionality with eco-friendliness, these cartridges stand out as a reputable choice. With continuous advancements and innovations, the future of filtration is closely intertwined with the potential of sintered stainless steel filter cartridges, making them a cornerstone of modern filtration strategies.

From an engineering perspective, one of the primary benefits of using these cartridges is their versatility. They are compatible with a wide range of systems and can be integrated into existing infrastructures without requiring significant modifications. Furthermore, the robustness of stainless steel ensures that the filters do not easily degrade, even under continuous use in harsh environments. This translates to considerable cost savings over time, as there is less need for frequent replacements or repairs. Sintered stainless steel filter cartridges also set industry benchmarks in terms of low-pressure drops during operation. This feature is particularly significant in processes where maintaining a constant flow is paramount. Lower pressure drops lead to increased energy efficiency, reducing the overall carbon footprint of the system. This aligns well with global efforts to improve energy efficiency standards and reduce environmental impacts. Trust in the performance of sintered stainless steel filter cartridges is backed by decades of research and development. Leading manufacturers conduct rigorous testing and quality control checks to ensure that every cartridge delivers optimal performance. Accredited certifications and compliance with international standards provide customers with peace of mind, knowing that they are investing in reliable and secure filtration systems. To conclude, sintered stainless steel filter cartridges represent the pinnacle of filtration technology. Their application across various industries is a testament to their superior quality, sustainability, and efficiency. As businesses continue to seek solutions that combine functionality with eco-friendliness, these cartridges stand out as a reputable choice. With continuous advancements and innovations, the future of filtration is closely intertwined with the potential of sintered stainless steel filter cartridges, making them a cornerstone of modern filtration strategies.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: