ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 16, 2025 05:00 Back to list

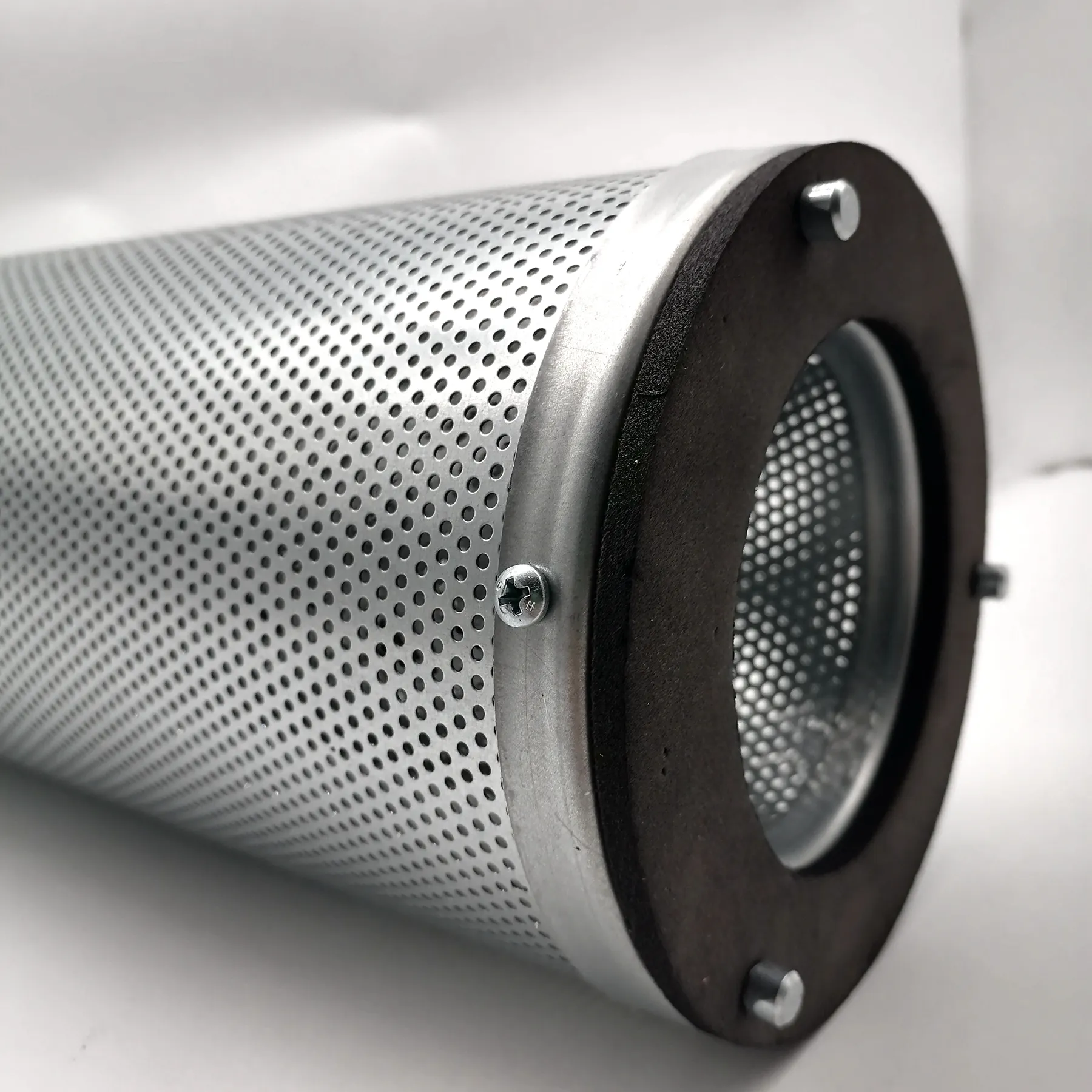

sintered filter element

The sintered filter element stands as a cornerstone in modern filtration technology, combining durability with exceptional filtration accuracy. This advanced component is a critical asset in diverse industrial applications due to its ability to filter particles while maintaining strong structural integrity under high pressure and temperature conditions.

Authoritativeness in the development and use of sintered filter elements comes from years of research and development in materials science. Top companies specializing in filtration technology have published numerous studies and papers that highlight the efficiency and reliability of sintered components. These elements are certified and tested according to international standards, such as ISO and ASTM, proving their adherence to quality benchmarks. Furthermore, industry leaders frequently choose sintered elements due to the proven track records in high-stakes environments like aerospace and pharmaceutical industries. Trustworthiness is inherent in the operational longevity and consistency of sintered filter elements. Users consistently report that these filters minimize contamination risks in sensitive processes, ensuring the purity and quality of the end product. Filters are regularly subjected to third-party assessments to guarantee that they meet safety and efficacy standards. Moreover, the materials used in the production of sintered filter elements are carefully selected for their non-reactive properties, eliminating any risk of chemical interaction with the filtered substances. In conclusion, sintered filter elements embody the pinnacle of filtration technology. Their design and construction benefit from decades of research and practical application across various sectors. As industries continue to evolve, the demand for reliable, high-performance filtration systems becomes ever more critical. Sintered filter elements offer not just filtration, but also peace of mind; their resilience, adaptability, and precision are unrivaled. For industries that require stringent filtration solutions, sintered filter elements represent an investment in quality, efficiency, and reliability, helping businesses maintain their competitive edge in an increasingly challenging market landscape.

Authoritativeness in the development and use of sintered filter elements comes from years of research and development in materials science. Top companies specializing in filtration technology have published numerous studies and papers that highlight the efficiency and reliability of sintered components. These elements are certified and tested according to international standards, such as ISO and ASTM, proving their adherence to quality benchmarks. Furthermore, industry leaders frequently choose sintered elements due to the proven track records in high-stakes environments like aerospace and pharmaceutical industries. Trustworthiness is inherent in the operational longevity and consistency of sintered filter elements. Users consistently report that these filters minimize contamination risks in sensitive processes, ensuring the purity and quality of the end product. Filters are regularly subjected to third-party assessments to guarantee that they meet safety and efficacy standards. Moreover, the materials used in the production of sintered filter elements are carefully selected for their non-reactive properties, eliminating any risk of chemical interaction with the filtered substances. In conclusion, sintered filter elements embody the pinnacle of filtration technology. Their design and construction benefit from decades of research and practical application across various sectors. As industries continue to evolve, the demand for reliable, high-performance filtration systems becomes ever more critical. Sintered filter elements offer not just filtration, but also peace of mind; their resilience, adaptability, and precision are unrivaled. For industries that require stringent filtration solutions, sintered filter elements represent an investment in quality, efficiency, and reliability, helping businesses maintain their competitive edge in an increasingly challenging market landscape.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: