ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 03, 2025 04:35 Back to list

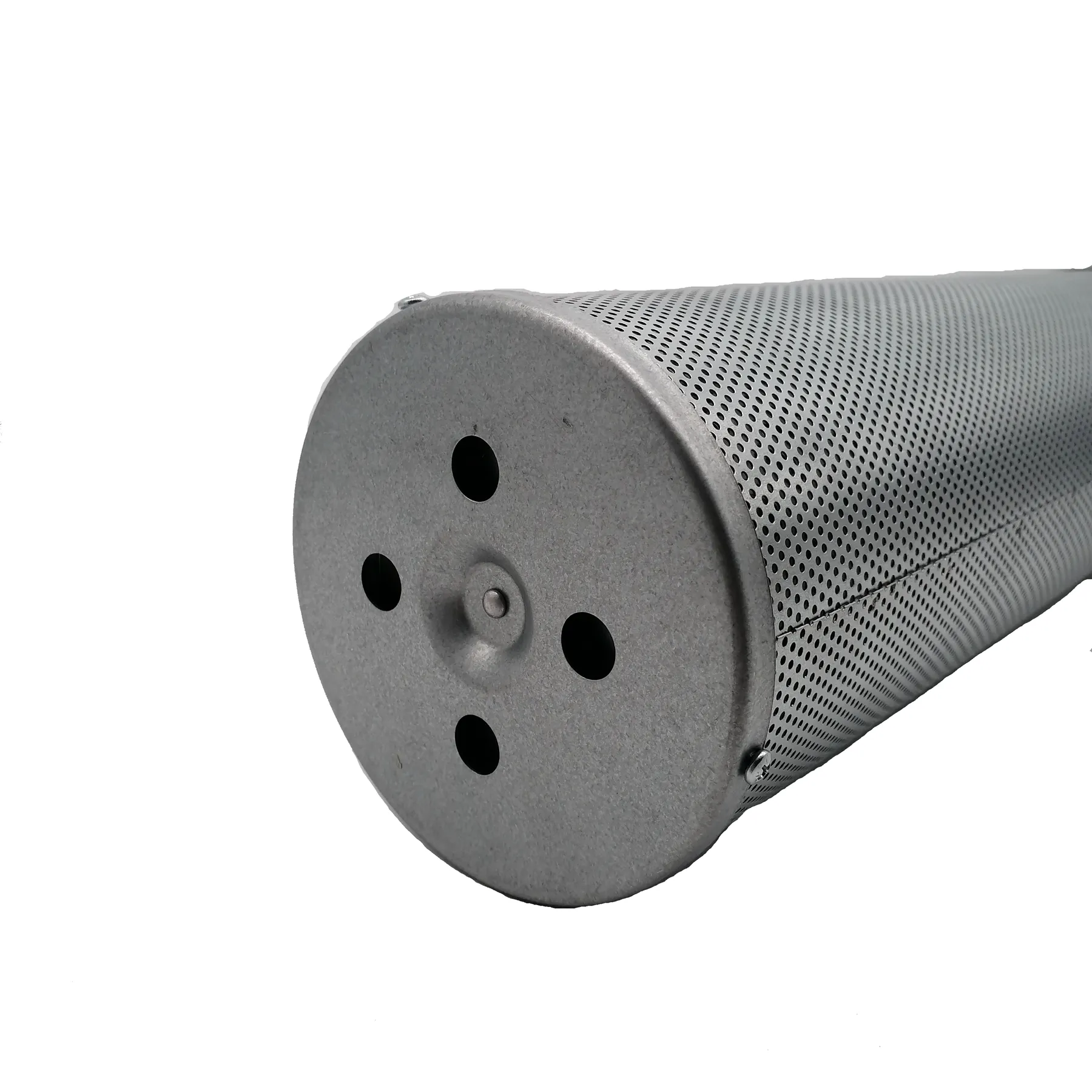

High performance industrial activated carbon filter cartridge

Sintered filter elements stand as a remarkable innovation in the filtration industry, offering a perfect amalgamation of durability, efficiency, and reliability. Manufactured using advanced sintering technologies, these filter elements are designed to provide superior filtration performance across various applications. Crafted from a range of high-quality materials such as stainless steel, bronze, and nickel, sintered filter elements are engineered to withstand high temperatures and corrosive environments, making them an ideal choice for demanding industrial settings.

The inherent advantages of sintered filter elements have spurred significant interest and application across various sectors. In the aerospace industry, for instance, their ability to ensure contaminant-free fuel and lubrication systems is critical for the safety and reliability of aircraft operations. Similarly, in water treatment facilities, their effectiveness in removing impurities contributes to the delivery of safe and clean water supplies. Their use extends beyond liquid filtration to encompass gas filtration and separation processes. In petrochemical plants, sintered filter elements are pivotal in purifying gases and protecting sensitive equipment from particulate matter. Their reliability in such high-stakes environments underscores their indispensability and showcases their value as a trusted filtration solution. To maximize the benefits derived from sintered filter elements, it is essential for industries to partner with reputable manufacturers who possess the necessary expertise and technological capabilities. A well-established manufacturer not only provides high-quality products but also offers valuable insights into optimizing filtration processes and achieving superior results. In conclusion, the integration of sintered filter elements within industrial operations presents a multitude of advantages that extend beyond mere filtration efficiency. Their robust design, coupled with superior resistance to harsh conditions and the ability to be customized, positions them as a cornerstone in enhancing process reliability and productivity. For industries across the board, investing in sintered filter technology signifies a commitment to innovation, sustainability, and operational excellence, ultimately driving long-term business success.

The inherent advantages of sintered filter elements have spurred significant interest and application across various sectors. In the aerospace industry, for instance, their ability to ensure contaminant-free fuel and lubrication systems is critical for the safety and reliability of aircraft operations. Similarly, in water treatment facilities, their effectiveness in removing impurities contributes to the delivery of safe and clean water supplies. Their use extends beyond liquid filtration to encompass gas filtration and separation processes. In petrochemical plants, sintered filter elements are pivotal in purifying gases and protecting sensitive equipment from particulate matter. Their reliability in such high-stakes environments underscores their indispensability and showcases their value as a trusted filtration solution. To maximize the benefits derived from sintered filter elements, it is essential for industries to partner with reputable manufacturers who possess the necessary expertise and technological capabilities. A well-established manufacturer not only provides high-quality products but also offers valuable insights into optimizing filtration processes and achieving superior results. In conclusion, the integration of sintered filter elements within industrial operations presents a multitude of advantages that extend beyond mere filtration efficiency. Their robust design, coupled with superior resistance to harsh conditions and the ability to be customized, positions them as a cornerstone in enhancing process reliability and productivity. For industries across the board, investing in sintered filter technology signifies a commitment to innovation, sustainability, and operational excellence, ultimately driving long-term business success.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: