ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 15, 2025 16:33 Back to list

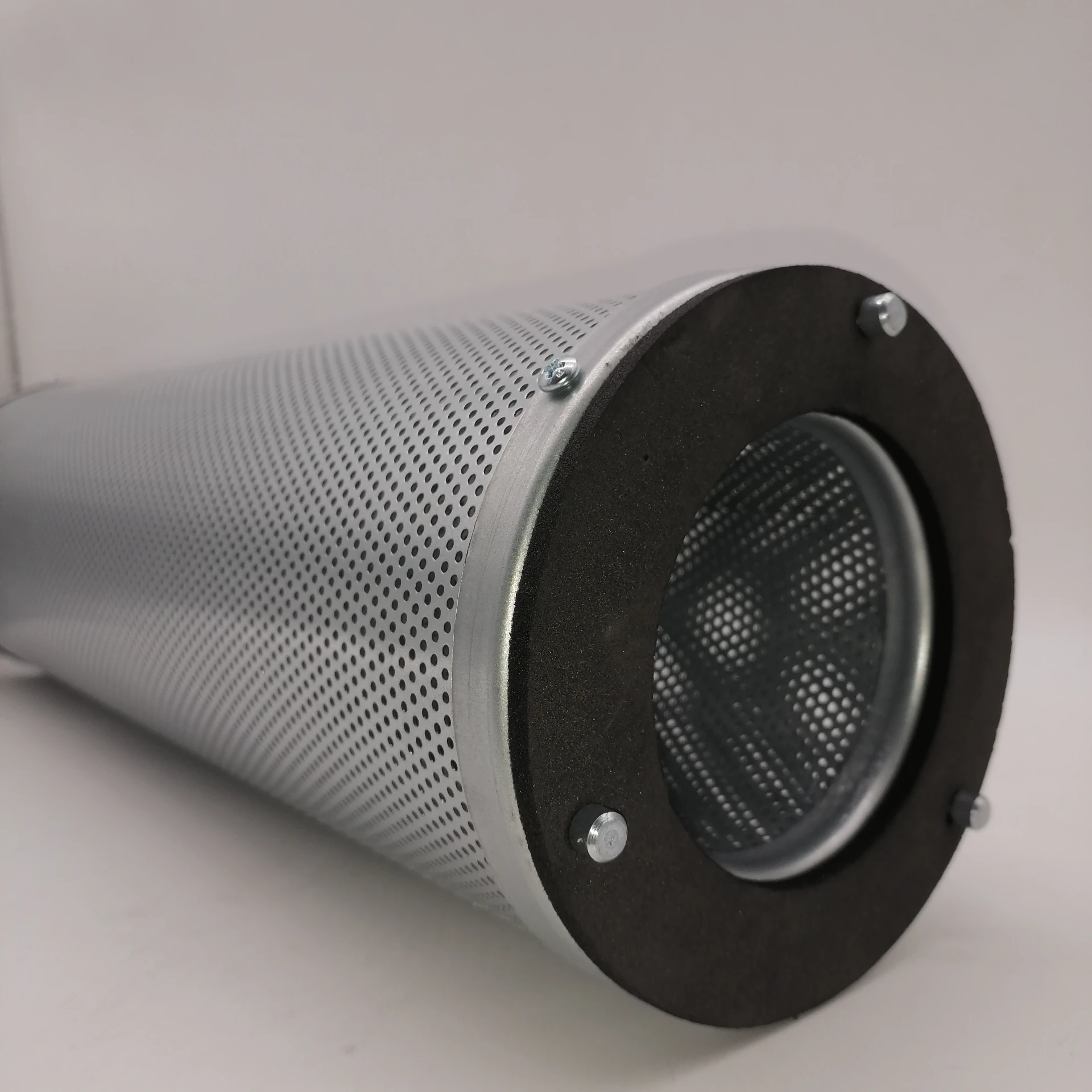

Air Filter High Performance Dust air compressor filter cartridge

In the ever-evolving landscape of industrial filtration, the silo filter cartridge stands as an indispensable component, offering unparalleled efficiency and reliability. As industries continue to expand and environmental regulations become more stringent, the demand for high-performance filtration solutions is at an all-time high. This necessity highlights the crucial role silo filter cartridges play in maintaining operational efficiency and compliance across various sectors.

Authoritativeness in the selection and implementation of silo filter cartridges comes from an in-depth understanding of the specific needs of each application. It is essential to consider factors such as the type of dust being filtered, the operational temperature range, and the spatial constraints of the installation environment. Leading manufacturers and filtration specialists provide consultation services to assist in the selection of the most appropriate cartridges, ensuring optimal performance and compliance with environmental standards. Trustworthiness in this field is underscored by the certifications and testing that these products undergo. Reputable manufacturers subject their silo filter cartridges to rigorous testing to verify performance standards such as ASHRAE or EN filtration efficiency ratings. These tests simulate the operational conditions that the cartridges will face, providing customers with confidence in their purchase. Furthermore, manufacturers may offer extensive warranties and after-sales support, enhancing the trust between them and their customers. Experience shows that regular maintenance and monitoring of silo filter cartridges are pivotal in prolonging their life and ensuring consistent performance. While these cartridges are designed for durability, the harsh environments in which they operate demand regular inspections to identify any wear or damage that could compromise their efficacy. Implementing a proactive maintenance program that includes periodic cleaning or replacement, calibration of filtration systems, and monitoring of airflow and differential pressure can significantly enhance the performance and reliability of these systems. In conclusion, the silo filter cartridge is not merely a component but a critical pillar supporting the operational success of industrial filtration systems. Its design excellence, unmatched efficiency, and durability make it a preferred choice for industries concerned with air quality and regulatory compliance. By understanding the intricate balance between design, application, and maintenance, businesses can make informed decisions that bolster their operational efficiency while adhering to environmental safeguards.

Authoritativeness in the selection and implementation of silo filter cartridges comes from an in-depth understanding of the specific needs of each application. It is essential to consider factors such as the type of dust being filtered, the operational temperature range, and the spatial constraints of the installation environment. Leading manufacturers and filtration specialists provide consultation services to assist in the selection of the most appropriate cartridges, ensuring optimal performance and compliance with environmental standards. Trustworthiness in this field is underscored by the certifications and testing that these products undergo. Reputable manufacturers subject their silo filter cartridges to rigorous testing to verify performance standards such as ASHRAE or EN filtration efficiency ratings. These tests simulate the operational conditions that the cartridges will face, providing customers with confidence in their purchase. Furthermore, manufacturers may offer extensive warranties and after-sales support, enhancing the trust between them and their customers. Experience shows that regular maintenance and monitoring of silo filter cartridges are pivotal in prolonging their life and ensuring consistent performance. While these cartridges are designed for durability, the harsh environments in which they operate demand regular inspections to identify any wear or damage that could compromise their efficacy. Implementing a proactive maintenance program that includes periodic cleaning or replacement, calibration of filtration systems, and monitoring of airflow and differential pressure can significantly enhance the performance and reliability of these systems. In conclusion, the silo filter cartridge is not merely a component but a critical pillar supporting the operational success of industrial filtration systems. Its design excellence, unmatched efficiency, and durability make it a preferred choice for industries concerned with air quality and regulatory compliance. By understanding the intricate balance between design, application, and maintenance, businesses can make informed decisions that bolster their operational efficiency while adhering to environmental safeguards.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: