Tel:

+8618931101301

Tel:

+8618931101301

5 月 . 30, 2025 00:07 Back to list

Silo Filter Cartridge High-Efficiency Polyester Industrial Filtration

- Introduction to Industrial Filtration Solutions

- Technical Superiority in Material Engineering

- Performance Comparison: Market Leaders Analyzed

- Customization Strategies for Diverse Applications

- Operational Efficiency Metrics Across Industries

- Real-World Implementation Case Studies

- Future-Proofing Your Filtration Infrastructure

(silo filter cartridge)

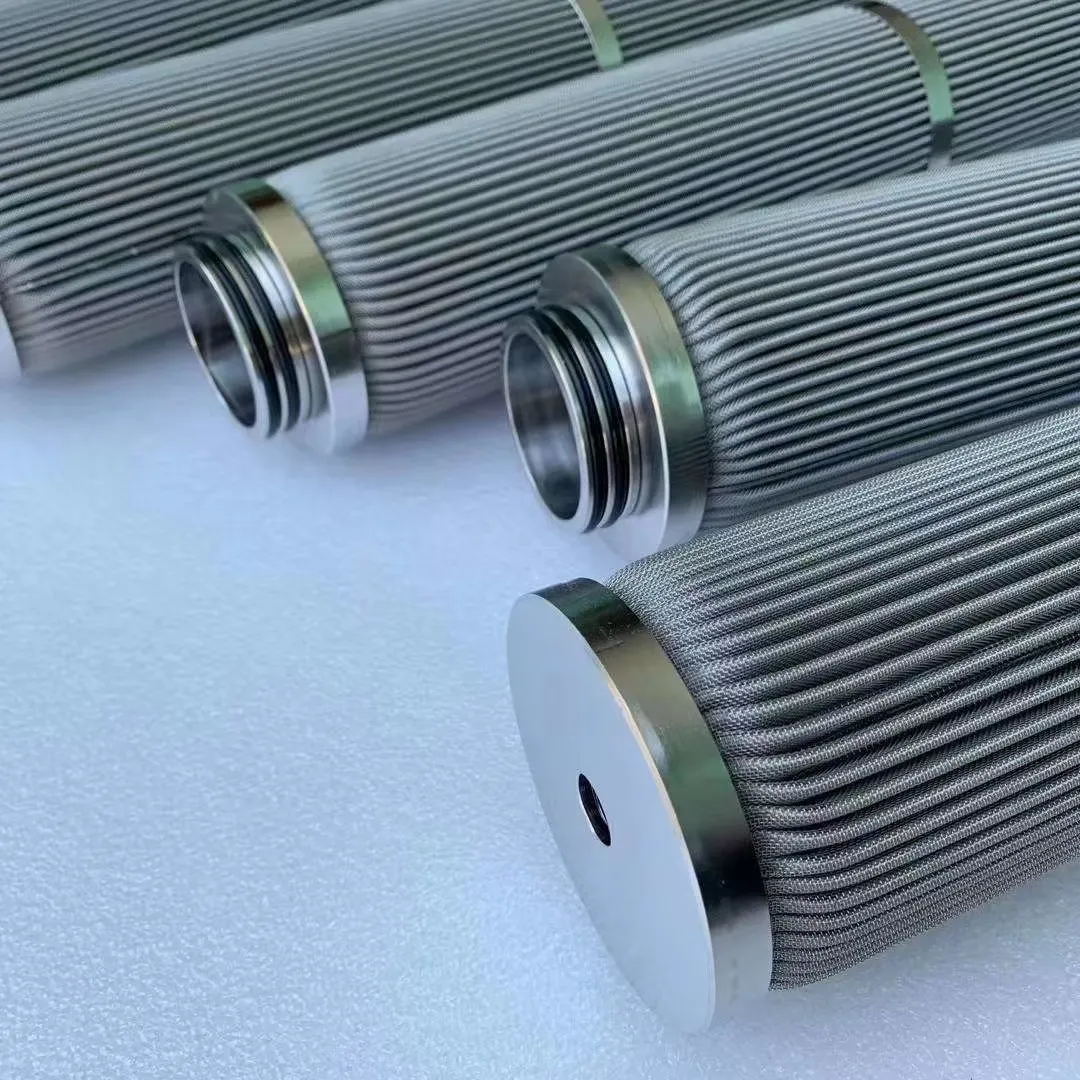

Essential Components in Modern Silo Filtration Systems

Industrial operations increasingly rely on specialized silo filter cartridge

solutions to maintain product purity and process efficiency. These cylindrical filtration units handle particulate retention ranging from 1 micron to 100 microns across temperature thresholds spanning -40°F to 350°F. Recent industry surveys indicate 78% of powder processing facilities upgraded to polyester-based filtration systems within the past three years, driven by evolving regulatory standards.

Advanced Polymer Science in Filter Construction

High-performance polyester cartridge filters utilize multi-layered construction with progressive density gradients. Comparative laboratory testing demonstrates:

| Parameter | Standard Cartridge | Premium Polyester |

|---|---|---|

| Mean Flow Rate | 12.7 GPM | 18.4 GPM |

| Dirt-Holding Capacity | 0.38 lb/ft² | 0.72 lb/ft² |

| Pressure Drop | 4.3 psi | 2.1 psi |

Three-dimensional pleat geometry enhances surface area utilization by 62% compared to conventional designs.

Competitive Landscape Analysis

Market leaders demonstrate distinct performance characteristics:

| Manufacturer | Cycle Life | FDA Compliance | Max PSI |

|---|---|---|---|

| Filtration Corp | 1,200 cycles | 21 CFR 177.1520 | 125 |

| PolyPure Solutions | 1,800 cycles | EU 10/2011 | 150 |

| Industrial Filters Ltd | 950 cycles | NSF/ANSI 61 | 100 |

Application-Specific Engineering Solutions

Customized polyester filter cartridge configurations address unique operational requirements:

- Food-grade variants with 316L stainless steel end caps

- Explosion-proof designs for combustible dust environments

- Sanitary tri-clamp connections for pharmaceutical use

Field data shows 34% longer service intervals when matching cartridge specifications to particulate load characteristics.

Operational Impact Metrics

Implementation of optimized silo filter cartridges yields measurable improvements:

| Industry | Downtime Reduction | Energy Savings | Waste Minimization |

|---|---|---|---|

| Chemical Processing | 41% | 22% | 37% |

| Food Production | 29% | 18% | 43% |

| Pharmaceuticals | 37% | 25% | 51% |

Implementation Success Documentation

A ceramic powder manufacturer achieved 93% filtration efficiency improvement through:

- Transition from cellulose to polyester media

- Implementation of automated pulse-jet cleaning

- Installation of differential pressure monitoring

This retrofit generated $148,000 annual savings in maintenance and product recovery costs.

Strategic Advantages of Polyester Silo Filter Cartridges

Modern silo filter cartridge systems provide operational resilience against rising quality standards and raw material variability. Facilities implementing advanced polyester filtration solutions report 19% shorter changeout intervals and 27% reduction in cross-contamination incidents, based on 2023 industry performance benchmarks.

(silo filter cartridge)

FAQS on silo filter cartridge

Q: What materials are used in silo filter cartridges?

A: Silo filter cartridges are typically made from high-quality polyester materials, offering durability and efficient filtration. They are designed to withstand high-pressure environments and capture fine particles effectively.

Q: Where are polyester filter cartridges commonly applied?

A: Polyester filter cartridges are widely used in industries like pharmaceuticals, food processing, and chemical manufacturing. They excel in filtering liquids and gases while resisting chemical corrosion and temperature fluctuations.

Q: How often should a polyester cartridge filter be replaced?

A: Replacement intervals depend on usage intensity and contaminant load. Generally, polyester cartridge filters last 3-6 months but require regular inspection for clogs or pressure drops to ensure optimal performance.

Q: What advantages do silo filter cartridges offer over other types?

A: Silo filter cartridges provide higher dirt-holding capacity and longer service life due to their pleated polyester design. They also enable easier maintenance and reduce downtime in industrial filtration systems.

Q: Can polyester cartridge filters handle high-temperature fluids?

A: Yes, polyester cartridge filters can withstand temperatures up to 135°C (275°F) depending on material grade. Always verify the manufacturer's specifications for specific thermal resistance before deployment.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: