Tel:

+8618931101301

Tel:

+8618931101301

9 月 . 20, 2024 03:59 Back to list

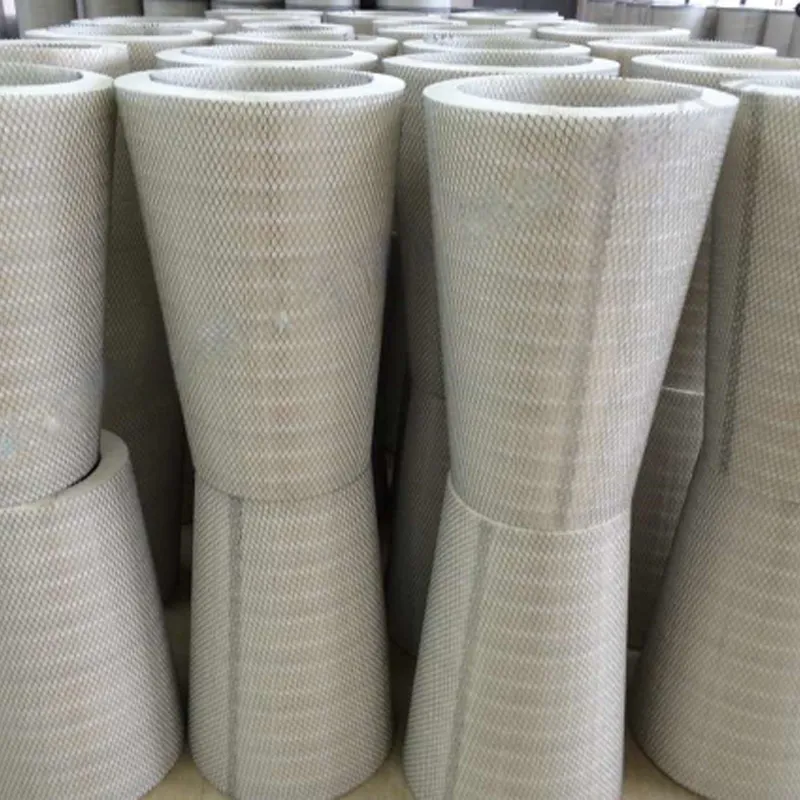

silo filter cartridge

Understanding the Importance of Silo Filter Cartridges

In various industrial processes, the need for effective dust and particulate control is paramount. One device that plays a crucial role in ensuring clean air and efficient operations is the silo filter cartridge. These cartridges are specially designed to filter out dust and particulates that can accumulate within silos, which are commonly used for storing bulk materials like grain, cement, and other powders.

What is a Silo Filter Cartridge?

A silo filter cartridge is a component of a dust collection system, commonly utilized in industries that handle dry bulk materials. These cartridges are typically made from advanced filtration media that can capture a wide range of particulate sizes. They are designed to fit into a filter housing, where they function by allowing air to pass through while trapping dust and particulates on their surface. This process not only protects the environment by reducing airborne dust but also helps maintain the quality of the stored materials by preventing contamination.

How Do Silo Filter Cartridges Work?

The operation of a silo filter cartridge revolves around the principles of filtration. When air containing dust enters the cartridge, it passes through the filter media, where larger particles are trapped. Over time, as more dust accumulates, a layer of collected dust forms on the cartridge surface. This layer can actually enhance filtration efficiency by capturing smaller particles that might otherwise pass through the filter.

To maintain optimal function, periodic cleaning or replacement of the filter cartridges is necessary. Many systems use pulse jet cleaning technology, where short bursts of compressed air are released to dislodge the accumulated dust, allowing it to fall into a collection hopper below.

silo filter cartridge

Benefits of Using Silo Filter Cartridges

1. Air Quality Improvement One of the primary benefits of using silo filter cartridges is the significant improvement in air quality. By effectively capturing dust particles, these cartridges help reduce respiratory hazards for workers and minimize the environmental impact.

2. Regulatory Compliance Many industries are subject to strict regulations regarding airborne emissions. Using high-quality filter cartridges is essential for ensuring compliance with local and international environmental standards.

3. Enhanced Material Quality Keeping dust out of silos helps protect the quality of stored materials. This is especially critical in industries such as food processing and pharmaceuticals, where contamination can have serious consequences.

4. Cost Efficiency By maintaining a clean environment and preventing product loss due to contamination, companies can save on costs associated with waste and non-compliance fines. Additionally, efficient dust collection can reduce energy consumption in transport systems.

Conclusion

In conclusion, silo filter cartridges play a vital role in various industries where dust control is essential. They contribute to improved air quality, regulatory compliance, enhanced material integrity, and overall cost savings. As industries continue to prioritize sustainability and operational efficiency, the importance of effective filtration solutions like silo filter cartridges will only grow. Investing in the right filter cartridges and maintaining them properly can lead to significant long-term benefits for businesses and the environment alike.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: