ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 11, 2025 08:02 Back to list

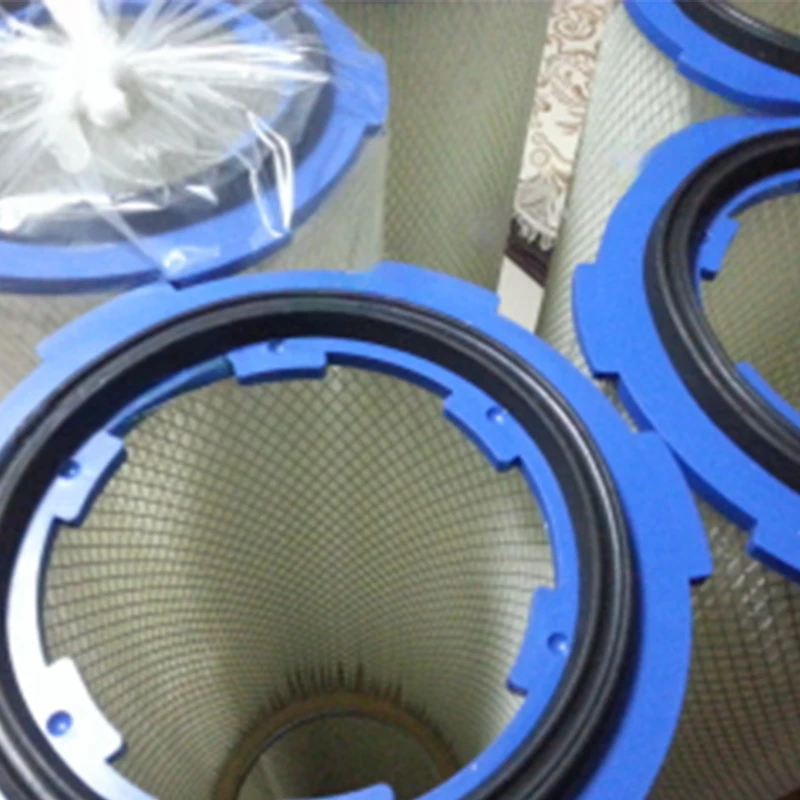

road roller air filter

Road roller air filters are the unsung heroes of construction machinery. Operating in dusty, harsh environments, these filters are crucial for maintaining the performance and longevity of road rollers. When properly maintained, they ensure that the engine operates efficiently, preventing costly repairs and downtime. Here, we'll explore the significance of road roller air filters, advice for selection and maintenance, based on expertise in the field.

Central to understanding air filter performance is the concept of restricted breathing. As filters get clogged, they restrict the airflow to the engine. This leads to poor combustion, increased fuel consumption, and ultimately, more exhaust emissions. The impact is not just environmental but also economic, given today's stringent regulations on emissions and operational efficacy. Keeping filters clean or replaced can lead to substantial cost savings over time. Users often report notable improvements in engine performance and machine uptime when adopting proactive filter maintenance programs. Documented cases within the industry have shown that neglecting air filter maintenance can lead to catastrophic engine failures. This reinforces the point that air filters, although inexpensive when compared to other components, are vital in safeguarding much larger investments. The trustworthiness of air filter guidance must be emphasized. Consulting with manufacturers or certified technicians can provide an authoritative understanding of specific filters and their suitability. This dialogue often uncovers crucial insights into product innovations or intricate benefits that might not be immediately evident. Finally, keep abreast of developments in air filter technology. The industry is continuously evolving, with advancements focusing on enhancing filtration efficiency and durability. Emerging technologies may offer better solutions that improve airflow or increase the dust capacity without any added bulk or complexity. In summary, road roller air filters may seem a minor component, but their impact on machine performance and cost effectiveness is significant. Proper selection, maintenance, and expert guidance play pivotal roles in maximizing their benefits, ensuring operational excellence and extended equipment life. Investing in quality air filters and expert advice ultimately reflects a commitment to maintaining superior construction machinery performance and reliability.

Central to understanding air filter performance is the concept of restricted breathing. As filters get clogged, they restrict the airflow to the engine. This leads to poor combustion, increased fuel consumption, and ultimately, more exhaust emissions. The impact is not just environmental but also economic, given today's stringent regulations on emissions and operational efficacy. Keeping filters clean or replaced can lead to substantial cost savings over time. Users often report notable improvements in engine performance and machine uptime when adopting proactive filter maintenance programs. Documented cases within the industry have shown that neglecting air filter maintenance can lead to catastrophic engine failures. This reinforces the point that air filters, although inexpensive when compared to other components, are vital in safeguarding much larger investments. The trustworthiness of air filter guidance must be emphasized. Consulting with manufacturers or certified technicians can provide an authoritative understanding of specific filters and their suitability. This dialogue often uncovers crucial insights into product innovations or intricate benefits that might not be immediately evident. Finally, keep abreast of developments in air filter technology. The industry is continuously evolving, with advancements focusing on enhancing filtration efficiency and durability. Emerging technologies may offer better solutions that improve airflow or increase the dust capacity without any added bulk or complexity. In summary, road roller air filters may seem a minor component, but their impact on machine performance and cost effectiveness is significant. Proper selection, maintenance, and expert guidance play pivotal roles in maximizing their benefits, ensuring operational excellence and extended equipment life. Investing in quality air filters and expert advice ultimately reflects a commitment to maintaining superior construction machinery performance and reliability.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: