ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

1 月 . 25, 2025 06:00 Back to list

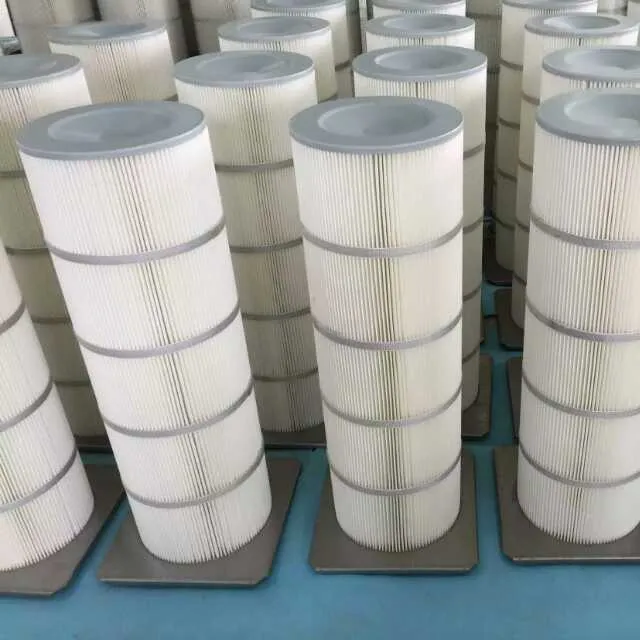

Air Filter High Performance Dust air compressor filter cartridge

The industrial world constantly seeks efficiency, reliability, and environmental sustainability. One of the breakthroughs facilitating these objectives is powder coating, a leading alternative to traditional paint methods. At the core of this technology's success lies the powder coating filter, an often-overlooked yet critical component that ensures high-quality finishes, optimal system performance, and safety compliance.

The trustworthiness of a powder coating filter directly affects production integrity and safety. Inferior or incorrectly specified filters can lead to operational inefficiencies, contamination issues, and even health risks if the overspray particulates are not adequately captured. To ensure reliability, it is prudent to source filters from reputable suppliers who provide transparent product testing results and certifications, such as ISO standards, to validate their efficacy and safety standards. Moreover, real-world experience underscores the necessity of regular maintenance and proper installation practices of powder coating filters. Experienced technicians highlight that even the best filters need consistent checks and adherence to the manufacturer's guidelines for replacement intervals. This proactive approach not only prolongs the life of the filter but also safeguards the coating systems from potential breakdowns, ensuring uninterrupted production sequences. Case studies from industry leaders reveal that investing in high-quality powder coating filters pays dividends in both operational efficiency and product quality. Companies that have optimized their filter systems report significant reductions in waste powder and improved finish quality, leading to customer satisfaction and heightened competitive advantage. Furthermore, these investments often align with corporate sustainability goals, promoting greener manufacturing practices by reducing environmental impact. In summary, while powder coating filters may seem like a minor component within the expansive operational system, their role is fundamentally pivotal. By incorporating expert knowledge, verifying the credibility of filter choices, and drawing from real-world experiences, businesses can harness these filters to enhance the quality, efficiency, and sustainability of their coating processes. As industries continue to evolve, those who prioritize informed decisions regarding their filtration systems will undoubtedly reap substantial rewards both in operational excellence and environmental stewardship.

The trustworthiness of a powder coating filter directly affects production integrity and safety. Inferior or incorrectly specified filters can lead to operational inefficiencies, contamination issues, and even health risks if the overspray particulates are not adequately captured. To ensure reliability, it is prudent to source filters from reputable suppliers who provide transparent product testing results and certifications, such as ISO standards, to validate their efficacy and safety standards. Moreover, real-world experience underscores the necessity of regular maintenance and proper installation practices of powder coating filters. Experienced technicians highlight that even the best filters need consistent checks and adherence to the manufacturer's guidelines for replacement intervals. This proactive approach not only prolongs the life of the filter but also safeguards the coating systems from potential breakdowns, ensuring uninterrupted production sequences. Case studies from industry leaders reveal that investing in high-quality powder coating filters pays dividends in both operational efficiency and product quality. Companies that have optimized their filter systems report significant reductions in waste powder and improved finish quality, leading to customer satisfaction and heightened competitive advantage. Furthermore, these investments often align with corporate sustainability goals, promoting greener manufacturing practices by reducing environmental impact. In summary, while powder coating filters may seem like a minor component within the expansive operational system, their role is fundamentally pivotal. By incorporating expert knowledge, verifying the credibility of filter choices, and drawing from real-world experiences, businesses can harness these filters to enhance the quality, efficiency, and sustainability of their coating processes. As industries continue to evolve, those who prioritize informed decisions regarding their filtration systems will undoubtedly reap substantial rewards both in operational excellence and environmental stewardship.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: