ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 10, 2025 11:08 Back to list

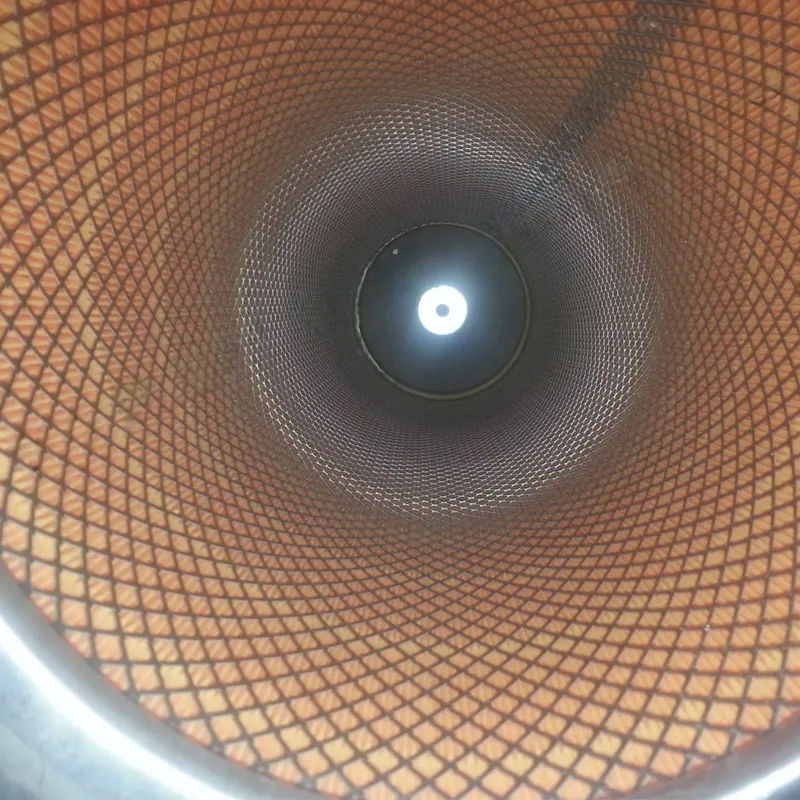

pleated dust collection cartridges

Pleated dust collection cartridges have become an indispensable component in industrial air purification systems. Their unique design and efficiency make them a preferred choice in numerous manufacturing and processing environments. By optimizing the airflow dynamics and enhancing particle capture, these cartridges improve overall system performance and extend equipment life.

Installation and maintenance of pleated dust collection cartridges are straightforward procedures that do not require specialized tools or knowledge, further enhancing their appeal. Regular inspection and timely replacement of these cartridges not only maintain system efficiency but also extend the life of ancillary components such as the dust collection unit's fan and motors. Users have found that a systematic maintenance schedule, guided by the manufacturer's recommendations and the specific working condition of the environment, yields the best results. Expert opinions from industry veterans emphasize the necessity of training personnel in the correct use and handling of these cartridges. Proper installation and removal procedures prevent damage to the filter media and ensure optimal performance. Training also encompasses the identification of potential operational issues, such as pressure drops or unusual noise, which can indicate the need for cartridge inspection or replacement. Another critical aspect of pleated dust collection cartridges is their environmental impact. Companies are increasingly prioritizing sustainable practices, and choosing the right filtration system plays a part in this. Many pleated cartridges are designed to be disposed of in an environmentally responsible manner, and some manufacturers offer recycling programs. Focusing on sustainable cartridge options can enhance a company's reputation as an environmentally conscious entity. Suppliers of pleated dust collection cartridges are also a key factor to consider. Partnering with reputable manufacturers who offer a range of products and customization options can provide long-term benefits. These suppliers bring a wealth of expertise to the table, ensuring that the chosen solutions meet technical and budgetary requirements while delivering superior performance. In conclusion, pleated dust collection cartridges are crucial in maintaining clean and safe air in industrial settings. Their design, efficiency, and adaptability offer compelling benefits, from cost savings and reduced maintenance to improved air quality and regulatory compliance. By prioritizing these cartridges, companies not only enhance their operational efficacy but also solidify their commitment to sustainability and workplace safety. Embracing this technology is a strategic decision that can provide both immediate and long-term advantages in the complex landscape of industrial air management.

Installation and maintenance of pleated dust collection cartridges are straightforward procedures that do not require specialized tools or knowledge, further enhancing their appeal. Regular inspection and timely replacement of these cartridges not only maintain system efficiency but also extend the life of ancillary components such as the dust collection unit's fan and motors. Users have found that a systematic maintenance schedule, guided by the manufacturer's recommendations and the specific working condition of the environment, yields the best results. Expert opinions from industry veterans emphasize the necessity of training personnel in the correct use and handling of these cartridges. Proper installation and removal procedures prevent damage to the filter media and ensure optimal performance. Training also encompasses the identification of potential operational issues, such as pressure drops or unusual noise, which can indicate the need for cartridge inspection or replacement. Another critical aspect of pleated dust collection cartridges is their environmental impact. Companies are increasingly prioritizing sustainable practices, and choosing the right filtration system plays a part in this. Many pleated cartridges are designed to be disposed of in an environmentally responsible manner, and some manufacturers offer recycling programs. Focusing on sustainable cartridge options can enhance a company's reputation as an environmentally conscious entity. Suppliers of pleated dust collection cartridges are also a key factor to consider. Partnering with reputable manufacturers who offer a range of products and customization options can provide long-term benefits. These suppliers bring a wealth of expertise to the table, ensuring that the chosen solutions meet technical and budgetary requirements while delivering superior performance. In conclusion, pleated dust collection cartridges are crucial in maintaining clean and safe air in industrial settings. Their design, efficiency, and adaptability offer compelling benefits, from cost savings and reduced maintenance to improved air quality and regulatory compliance. By prioritizing these cartridges, companies not only enhance their operational efficacy but also solidify their commitment to sustainability and workplace safety. Embracing this technology is a strategic decision that can provide both immediate and long-term advantages in the complex landscape of industrial air management.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: