ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 04, 2025 03:17 Back to list

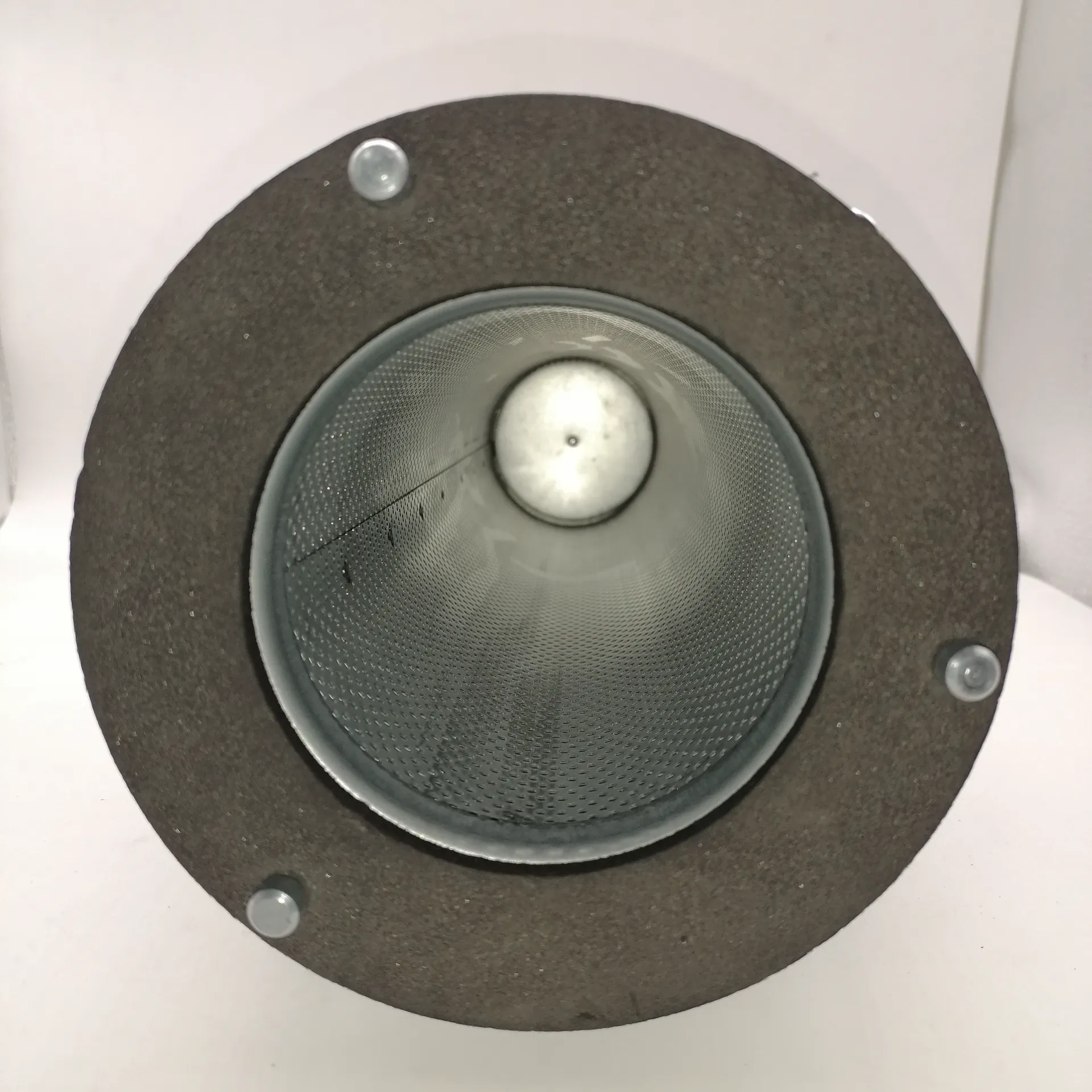

air filter for excavator

Having worked extensively with construction equipment, understanding the importance of maintaining machinery and facilitating their optimal functionality cannot be overstressed. A pivotal component often overlooked in the maintenance schedule of mini excavators is the air filter. This small yet mighty part serves as the first line of defense against contaminants that jeopardize engine performance and longevity.

In terms of authoritativeness, insights from leading manufacturers reveal that the most advanced air filters offer multi-stage filtration, effectively addressing both large debris and microscopic particles. Such technology not only ensures cleaner air intake but significantly extends the life of the excavator’s engine. Using genuine and high-quality filters as recommended by the machine’s manufacturer is crucial. Not only do they guarantee compatibility, but they also come with the assurance of rigorous testing and quality control, important factors in safeguarding engine health. Trustworthiness in the context of air filter maintenance is about consistency and routine checks. Regular inspection schedules can preempt performance issues, allowing operators to replace filters proactively rather than reactively. This preemptive approach was validated when a scheduled check revealed gradual dirt build-up in a mini excavator tasked with long-term forestry operations. By catching the issue early, significant engine wear was avoided, reducing downtime and repair costs. An additional element of trust arises from consulting with experienced professionals or trusted retailers who understand the intricacies involved in matching the appropriate filter to your specific machine and working condition. They can furnish advice beyond what manuals provide, often illuminating subtle differences in filter performance tied to specific brands or filter constructions. Environmentally, in regions with stringent emission standards, using high-performance air filters can also contribute to cleaner emissions, complementing larger fire-pollution reduction strategies essential in urban areas. In conclusion, the air filter is not merely a throwaway component but a vital part of maintaining mini excavator efficiency and longevity. Through expert selection, regular maintenance, and leveraging authoritative resources, operators can ensure their equipment runs smoothly in any environment. Balancing experience, expertise, authoritativeness, and trustworthiness allows you to elevate machinery care from routine to exceptional, underlining the fundamental role of air filters in optimizing equipment performance.

In terms of authoritativeness, insights from leading manufacturers reveal that the most advanced air filters offer multi-stage filtration, effectively addressing both large debris and microscopic particles. Such technology not only ensures cleaner air intake but significantly extends the life of the excavator’s engine. Using genuine and high-quality filters as recommended by the machine’s manufacturer is crucial. Not only do they guarantee compatibility, but they also come with the assurance of rigorous testing and quality control, important factors in safeguarding engine health. Trustworthiness in the context of air filter maintenance is about consistency and routine checks. Regular inspection schedules can preempt performance issues, allowing operators to replace filters proactively rather than reactively. This preemptive approach was validated when a scheduled check revealed gradual dirt build-up in a mini excavator tasked with long-term forestry operations. By catching the issue early, significant engine wear was avoided, reducing downtime and repair costs. An additional element of trust arises from consulting with experienced professionals or trusted retailers who understand the intricacies involved in matching the appropriate filter to your specific machine and working condition. They can furnish advice beyond what manuals provide, often illuminating subtle differences in filter performance tied to specific brands or filter constructions. Environmentally, in regions with stringent emission standards, using high-performance air filters can also contribute to cleaner emissions, complementing larger fire-pollution reduction strategies essential in urban areas. In conclusion, the air filter is not merely a throwaway component but a vital part of maintaining mini excavator efficiency and longevity. Through expert selection, regular maintenance, and leveraging authoritative resources, operators can ensure their equipment runs smoothly in any environment. Balancing experience, expertise, authoritativeness, and trustworthiness allows you to elevate machinery care from routine to exceptional, underlining the fundamental role of air filters in optimizing equipment performance.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: