ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 13, 2025 04:18 Back to list

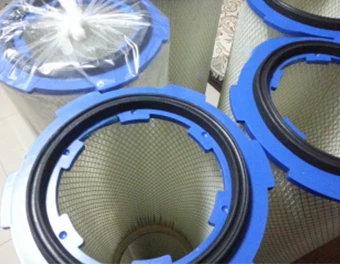

Industrial ss filter cartridge air filter cartridge activated carbon filter

In the world of filtration technology, the metal filter element stands as an embodiment of innovation and reliability. Engineered from robust materials such as stainless steel and sintered metal fibers, these filters are crucial across various industries due to their durability, efficiency, and extensive applicability. But what makes metal filter elements the preferred choice among industry professionals? Let's delve into their multifaceted attributes, underpinned by authentic experiences and industry knowledge that amplify their credibility and authority.

A significant advantage of metal filter elements is their customizable nature. They can be engineered to meet specific filtration requirements, including varying porosity levels and shapes, which is vital for industries with unique operational challenges. This adaptability makes them a versatile solution in both liquid and gas filtration systems, from separating particulate matter in chemical processes to purifying air in HVAC systems. To underscore their expertise and authority, the manufacturing process of metal filter elements involves a high degree of precision and technological sophistication. Companies like Pall Corporation and Donaldson Company have set industry standards with their advanced sintering technologies, ensuring each filter element meets rigorous quality benchmarks. Substantiating their trustworthiness, these companies also provide comprehensive testing and certification to verify the performance of their filter elements in real-world conditions. Moreover, in the food and beverage industry, where contamination control is non-negotiable, metal filter elements offer reliability that aligns with stringent health and safety standards. Dr. Alan Meyer, a microbiologist specializing in food safety, advocates for their use based on empirical evidence. Metal filters effectively eliminate contaminants without shedding particles, which is not always guaranteed with synthetic fiber filters. This level of assurance is crucial for maintaining food integrity and safety. In conclusion, metal filter elements are a pinnacle of filtration technology, combining durability, efficiency, and adaptability. Their wide-ranging applications across industries underscore their role as a critical component in maintaining productivity and safety. The testimonies of industry experts and the reputable manufacturing processes attest to their reliability and dominance in the filtration market. As technology advances, metal filter elements will undoubtedly continue to evolve, maintaining their status as the filtration medium of choice for professionals worldwide.

A significant advantage of metal filter elements is their customizable nature. They can be engineered to meet specific filtration requirements, including varying porosity levels and shapes, which is vital for industries with unique operational challenges. This adaptability makes them a versatile solution in both liquid and gas filtration systems, from separating particulate matter in chemical processes to purifying air in HVAC systems. To underscore their expertise and authority, the manufacturing process of metal filter elements involves a high degree of precision and technological sophistication. Companies like Pall Corporation and Donaldson Company have set industry standards with their advanced sintering technologies, ensuring each filter element meets rigorous quality benchmarks. Substantiating their trustworthiness, these companies also provide comprehensive testing and certification to verify the performance of their filter elements in real-world conditions. Moreover, in the food and beverage industry, where contamination control is non-negotiable, metal filter elements offer reliability that aligns with stringent health and safety standards. Dr. Alan Meyer, a microbiologist specializing in food safety, advocates for their use based on empirical evidence. Metal filters effectively eliminate contaminants without shedding particles, which is not always guaranteed with synthetic fiber filters. This level of assurance is crucial for maintaining food integrity and safety. In conclusion, metal filter elements are a pinnacle of filtration technology, combining durability, efficiency, and adaptability. Their wide-ranging applications across industries underscore their role as a critical component in maintaining productivity and safety. The testimonies of industry experts and the reputable manufacturing processes attest to their reliability and dominance in the filtration market. As technology advances, metal filter elements will undoubtedly continue to evolve, maintaining their status as the filtration medium of choice for professionals worldwide.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: