Tel:

+8618931101301

Tel:

+8618931101301

9 月 . 02, 2024 18:20 Back to list

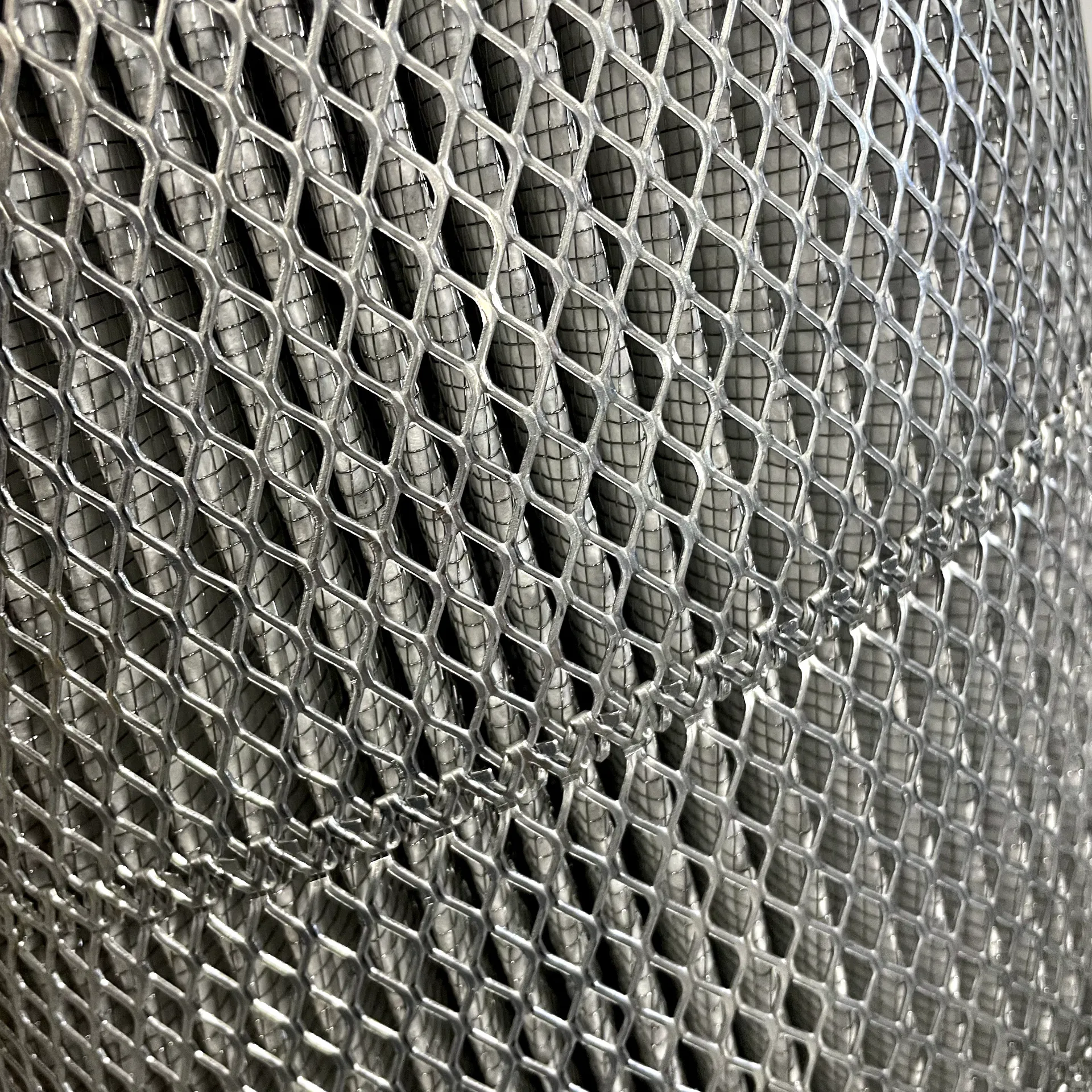

High-Performance Metal Filter Elements for Industrial Applications

Understanding Metal Filter Elements An In-Depth Analysis

In industrial and commercial applications, the need for effective filtration systems is paramount. Among the various types of filter elements available, metal filter elements have gained significant attention due to their durability, efficiency, and versatility. This article delves into the various aspects of metal filter elements, exploring their benefits, applications, and the reasons behind their growing popularity.

What Are Metal Filter Elements?

Metal filter elements are filtration devices made from various metals, including stainless steel, aluminum, and other alloys. These filters are designed to separate contaminants and particles from fluids or gases, ensuring that the output is clean and free from unwanted materials. The construction of metal filter elements allows them to withstand high temperatures, pressures, and corrosive environments, making them ideal for a range of demanding applications.

Advantages of Metal Filter Elements

1. Durability and Longevity One of the most significant advantages of metal filter elements is their durability. Unlike their cloth or paper counterparts, metal filters can endure harsh conditions and last significantly longer, resulting in lower replacement costs in the long run. They do not easily degrade or tear, making them suitable for continuous use in challenging environments.

2. High-Temperature Resistance Metal filter elements can operate effectively at elevated temperatures, which is essential in applications like aerospace, automotive, and manufacturing processes where high heat is common. Their ability to maintain structural integrity at high temperatures ensures consistent performance.

metal filter element

3. Reusability and Cleanability Many metal filter elements are designed to be cleaned and reused. This feature not only conserves resources but also reduces waste and lowers operational costs. Depending on the application, metal filters can be backwashed, steam-cleaned, or chemically cleaned, providing a sustainable solution for filtration needs.

4. Versatile Filtration Metal filters can accommodate a wide range of filtration needs, from coarse particulate removal to fine filtration. They can be manufactured in various pore sizes and configurations, allowing them to be tailored for specific applications. This versatility makes them suitable for industries such as food and beverage, pharmaceuticals, petrochemicals, and more.

5. Enhanced Filtration Performance The design of metal filter elements often incorporates advanced features such as multi-layer filtration and gradient structures which enhance their efficiency in capturing contaminants. This leads to improved overall system performance and product quality.

Applications of Metal Filter Elements

Metal filter elements are employed across diverse sectors. In the food and beverage industry, they ensure the purity of products by filtering out debris and microorganisms. In the chemical and petrochemical industries, they play a critical role in protecting equipment from contamination, ensuring smooth operations. Additionally, in aerospace and automotive industries, these filters help in maintaining clean hydraulic systems and engines.

Conclusion

The importance of effective filtration cannot be overstated, and metal filter elements offer a robust solution to meet the stringent demands of various industries. Their durability, high-temperature resistance, reusability, and versatility make them an ideal choice for many applications. As industries continue to seek efficient and sustainable solutions, the adoption of metal filter elements is likely to expand, further solidifying their role in advanced filtration technology. Understanding these elements and their benefits is crucial for any organization looking to enhance their filtration processes and ensure the quality and safety of their products.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: