ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 16, 2025 10:05 Back to list

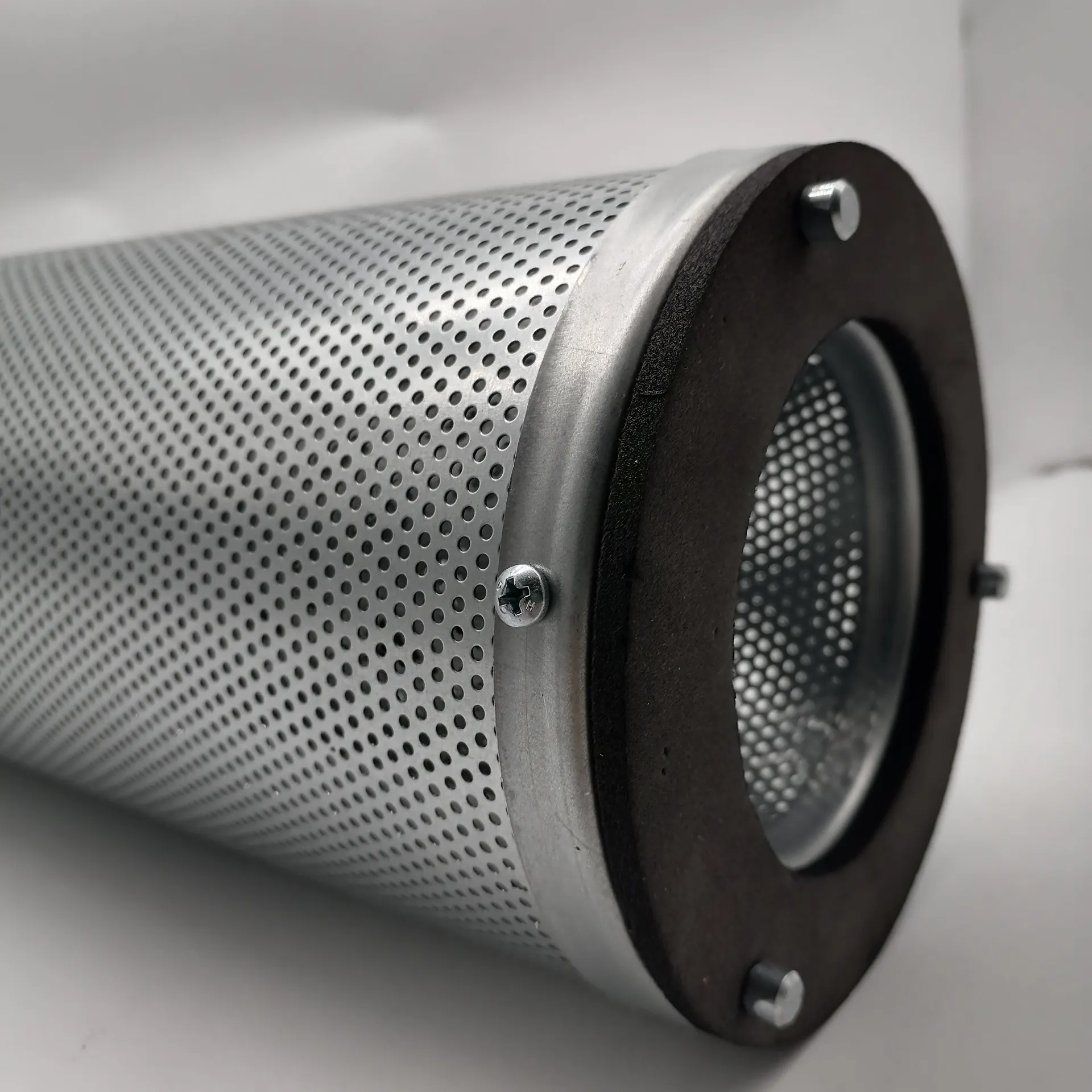

Air Filter High Performance Dust air compressor filter cartridge

In the realm of heavy machinery, the loader air filter stands as an unsung hero, playing a pivotal role in ensuring optimal performance and longevity of equipment. While its significance is often overshadowed by more prominent components, the air filter's contribution to a loader’s operation is nothing short of indispensable.

With expertise rooted in understanding both the technical and operational aspects of loaders, businesses can strategize maintenance that aligns with workload and environmental exposure. For instance, loaders operating in highly dust-prone environments should consider pre-filters or upgraded filter media that offer enhanced protection. Professional insights advise paying attention to the filter's dust-holding capacity and its ability to withstand varied ambient conditions, an important consideration for maximizing coercive forces acting on the engine. Establishing a credible voice in loader maintenance best practices involves empirical data drawn from field studies and manufacturer insights. The authoritativeness of such information stems from well-documented case studies where clients witnessed a marked improvement in operational efficiency following an overhaul of their air filter management practices. A robust maintenance routine, backed by comprehensive data, showcases not just adherence to manufacturer guidelines but also an advanced application that takes into account site-specific challenges. Trustworthiness is integral to gaining acceptance and compliance from operators and maintenance personnel. Building a culture of trust in air filter maintenance involves transparency in communication, providing straightforward access to maintenance records, and demonstrating tangible results from suggested practices. Operators appreciate evidence-based results that highlight reduced downtime and increased machine longevity, ultimately fortifying the trust in recommended practices. Ultimately, the loader air filter serves as the linchpin in preventive maintenance protocols. Its role in the seamless operation of machinery cannot be overstated. By marrying technical expertise with practical experience, businesses can harness the full potential of their loaders, ensuring that these critical pieces of equipment continue to operate efficiently, safely, and economically. Investing time and resources into understanding and maintaining air filters is not merely about preventing failure—it's about affirming commitment to quality, reliability, and the long-term success of operational goals.

With expertise rooted in understanding both the technical and operational aspects of loaders, businesses can strategize maintenance that aligns with workload and environmental exposure. For instance, loaders operating in highly dust-prone environments should consider pre-filters or upgraded filter media that offer enhanced protection. Professional insights advise paying attention to the filter's dust-holding capacity and its ability to withstand varied ambient conditions, an important consideration for maximizing coercive forces acting on the engine. Establishing a credible voice in loader maintenance best practices involves empirical data drawn from field studies and manufacturer insights. The authoritativeness of such information stems from well-documented case studies where clients witnessed a marked improvement in operational efficiency following an overhaul of their air filter management practices. A robust maintenance routine, backed by comprehensive data, showcases not just adherence to manufacturer guidelines but also an advanced application that takes into account site-specific challenges. Trustworthiness is integral to gaining acceptance and compliance from operators and maintenance personnel. Building a culture of trust in air filter maintenance involves transparency in communication, providing straightforward access to maintenance records, and demonstrating tangible results from suggested practices. Operators appreciate evidence-based results that highlight reduced downtime and increased machine longevity, ultimately fortifying the trust in recommended practices. Ultimately, the loader air filter serves as the linchpin in preventive maintenance protocols. Its role in the seamless operation of machinery cannot be overstated. By marrying technical expertise with practical experience, businesses can harness the full potential of their loaders, ensuring that these critical pieces of equipment continue to operate efficiently, safely, and economically. Investing time and resources into understanding and maintaining air filters is not merely about preventing failure—it's about affirming commitment to quality, reliability, and the long-term success of operational goals.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: