Tel:

+8618931101301

Tel:

+8618931101301

12 月 . 04, 2024 15:55 Back to list

Exploring the Importance of Loader Air Filters for Enhanced Performance and Longevity

The Importance of Loader Air Filters Keeping Performance at Peak Levels

When it comes to the performance and longevity of heavy machinery, loader air filters play a critical role. These components are often overlooked in the vast world of construction and agricultural equipment, yet they embody a fundamental aspect of machine efficiency and reliability. Understanding the importance of loader air filters can help operators and fleet managers maintain equipment performance and extend machine life.

What is a Loader Air Filter?

A loader air filter is an essential component of a loader's engine system. Its primary function is to purify the air entering the engine, preventing dust, dirt, and other contaminants from causing harm. Given that loaders often work in environments filled with debris—such as construction sites, quarries, and farms—a high-quality air filter is crucial. In essence, the loader air filter acts as a barrier, safeguarding the engine and allowing it to operate effectively.

How Air Filters Affect Engine Performance

The engine is fundamentally a combustion engine, and like any combustion process, it requires a precise mixture of air and fuel to operate efficiently. The cleaner the air entering the engine, the better the combustion process, which directly translates to improved performance and fuel efficiency. A clogged or dirty air filter can severely restrict airflow to the engine, resulting in a poor air-fuel mixture that leads to diminished performance, higher fuel consumption, and increased emissions.

In practical terms, a loader with a dirty air filter often experiences reduced power output, sluggish acceleration, and increased operational costs. Furthermore, when an engine runs with insufficient air flow, it can lead to more severe outcomes, including engine wear and damage. Therefore, maintaining a clean loader air filter is essential not just for performance, but also for the overall health of the engine.

Signs of a Bad Air Filter

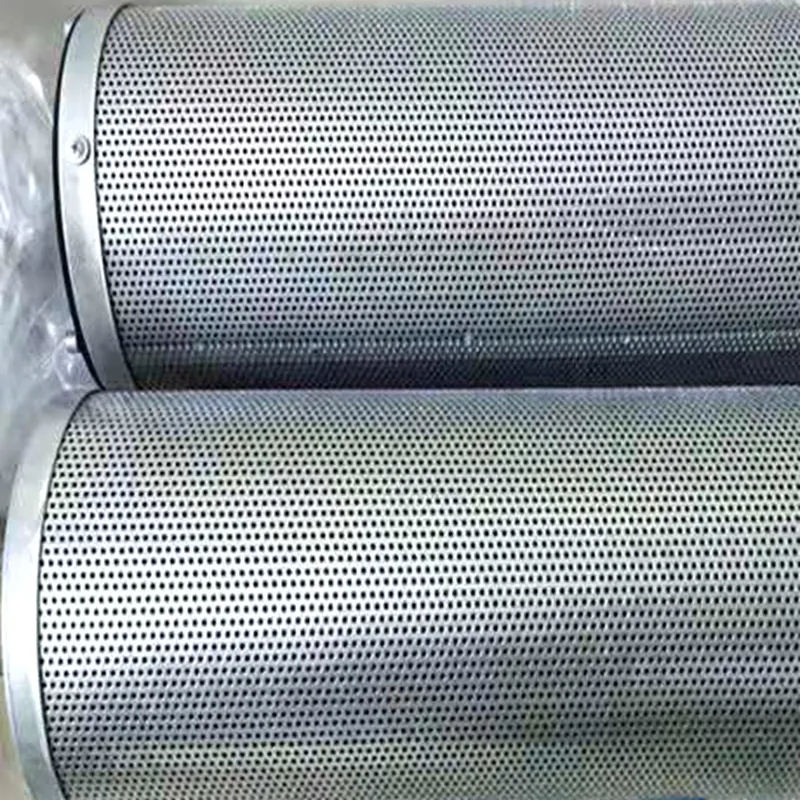

loader air filter

Recognizing when an air filter needs replacement is vital for maintaining loader efficiency. Operators should be aware of several key indicators that signal a problem. Common signs of a clogged air filter include

1. Decreased Performance If the loader seems less powerful, struggles to lift loads, or has a sluggish response, it may be time to check the air filter. 2. Increased Fuel Consumption A higher-than-usual fuel consumption rate can also indicate that the engine is not receiving adequate air. 3. Black Smoke from the Exhaust This could signal an improper fuel-air mix due to a blocked filter, resulting in unburned fuel. 4. Check Engine Light Activation Naturally, any dashboard indicators should not be ignored. A check engine light may also be linked to air intake issues.

Regular Maintenance and Best Practices

To ensure optimal performance, routine maintenance of the loader air filter is essential. Regularly inspecting and replacing air filters according to the manufacturer's guidelines can help avoid performance drops and costly repairs down the line. Working in dusty environments may necessitate more frequent replacements than normal.

1. Inspection Make it a habit to inspect the air filter visually every few weeks. If it appears dirty or discolored, it’s time for replacement. 2. Replacement Schedule Follow a regular filter replacement schedule based on operating hours. Many manufacturers recommend replacing the air filter every 250 to 500 operating hours, but this can vary. 3. High-Quality Filters Always opt for OEM (Original Equipment Manufacturer) filters. While aftermarket filters can often be cheaper, they may not offer the same level of protection and efficiency as those specifically designed for the loader model.

Conclusion

Ultimately, loader air filters are far more than just simple components; they are crucial to the overall efficiency, performance, and longevity of heavy machinery. Regular checks, timely replacements, and the use of high-quality products can keep loaders running smoothly, ultimately leading to increased productivity and reduced operating costs. By paying attention to the health of the air filter, operators can ensure that their machines perform at their best, regardless of the challenges presented by job sites. Adopting a proactive approach to air filter maintenance is a small yet significant step toward maximizing equipment performance and reliability.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: