ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

1 月 . 19, 2025 02:54 Back to list

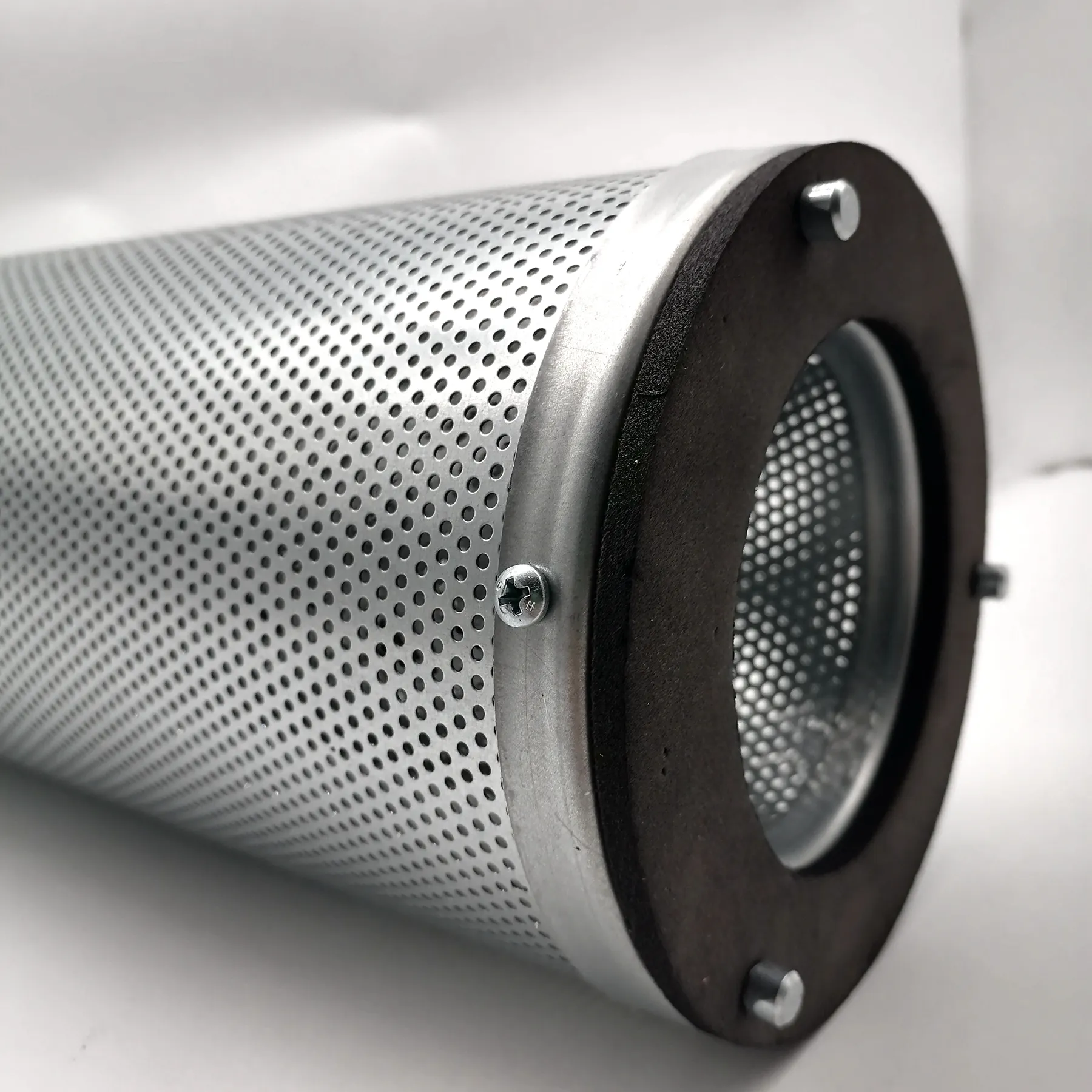

truck air filter

Finding the right heavy truck cartridge air filter paper plays a crucial role in maintaining the performance and longevity of heavy-duty trucks. As the backbone of the modern logistics industry, heavy trucks endure challenging environments and high operational demands. Therefore, their air filtration systems must be up to the task of filtering contaminants while allowing sufficient airflow to maintain engine efficiency. Here's an in-depth analysis to help you understand why investing in high-quality cartridge air filter paper is a wise decision for heavy truck maintenance and operation.

Industry Authority and Certification Standards When selecting a heavy truck cartridge air filter, it's vital to consider whether the product adheres to industry standards and certifications, such as those from the ISO (International Organization for Standardization) or the SAE (Society of Automotive Engineers). These certifications ensure that the filter paper has undergone rigorous testing for performance and reliability, which further establishes the product’s credibility and the manufacturer's commitment to quality assurance. Building Trust through Proven Results Case studies from transport companies and fleet operators often reveal insights into the overall performance improvements and cost savings realized through the use of high-quality cartridge air filter papers. These real-world applications often highlight a reduction in maintenance downtime, improved engine life, and significant savings on fuel expenditure, reinforcing trust and confidence in reputable filter brands and their products. Future Trends in Air Filter Paper Technology The heavy truck industry continues to evolve with advancements in materials science and engineering leading to more efficient air filter papers. Nanotechnology is making its way into filter production, offering improved filtration capabilities and enhanced durability. As these technologies become mainstream, operators can expect even better protection for their truck engines, contributing to lower environmental impact through enhanced fuel efficiencies and emissions control. Closing Remarks on Best Practices Investing in high-quality heavy truck cartridge air filter paper is not merely an operational decision but a strategic one. It involves balancing performance capabilities with cost considerations while ensuring compliance with safety and environmental standards. By focusing on recognized brands, adhering to expert maintenance guidelines, and staying informed about technological advancements, truck operators and fleet managers can ensure their vehicles are well-protected and operate at peak efficiency, ultimately leading to a more profitable operation.

Industry Authority and Certification Standards When selecting a heavy truck cartridge air filter, it's vital to consider whether the product adheres to industry standards and certifications, such as those from the ISO (International Organization for Standardization) or the SAE (Society of Automotive Engineers). These certifications ensure that the filter paper has undergone rigorous testing for performance and reliability, which further establishes the product’s credibility and the manufacturer's commitment to quality assurance. Building Trust through Proven Results Case studies from transport companies and fleet operators often reveal insights into the overall performance improvements and cost savings realized through the use of high-quality cartridge air filter papers. These real-world applications often highlight a reduction in maintenance downtime, improved engine life, and significant savings on fuel expenditure, reinforcing trust and confidence in reputable filter brands and their products. Future Trends in Air Filter Paper Technology The heavy truck industry continues to evolve with advancements in materials science and engineering leading to more efficient air filter papers. Nanotechnology is making its way into filter production, offering improved filtration capabilities and enhanced durability. As these technologies become mainstream, operators can expect even better protection for their truck engines, contributing to lower environmental impact through enhanced fuel efficiencies and emissions control. Closing Remarks on Best Practices Investing in high-quality heavy truck cartridge air filter paper is not merely an operational decision but a strategic one. It involves balancing performance capabilities with cost considerations while ensuring compliance with safety and environmental standards. By focusing on recognized brands, adhering to expert maintenance guidelines, and staying informed about technological advancements, truck operators and fleet managers can ensure their vehicles are well-protected and operate at peak efficiency, ultimately leading to a more profitable operation.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: