ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 11, 2025 03:16 Back to list

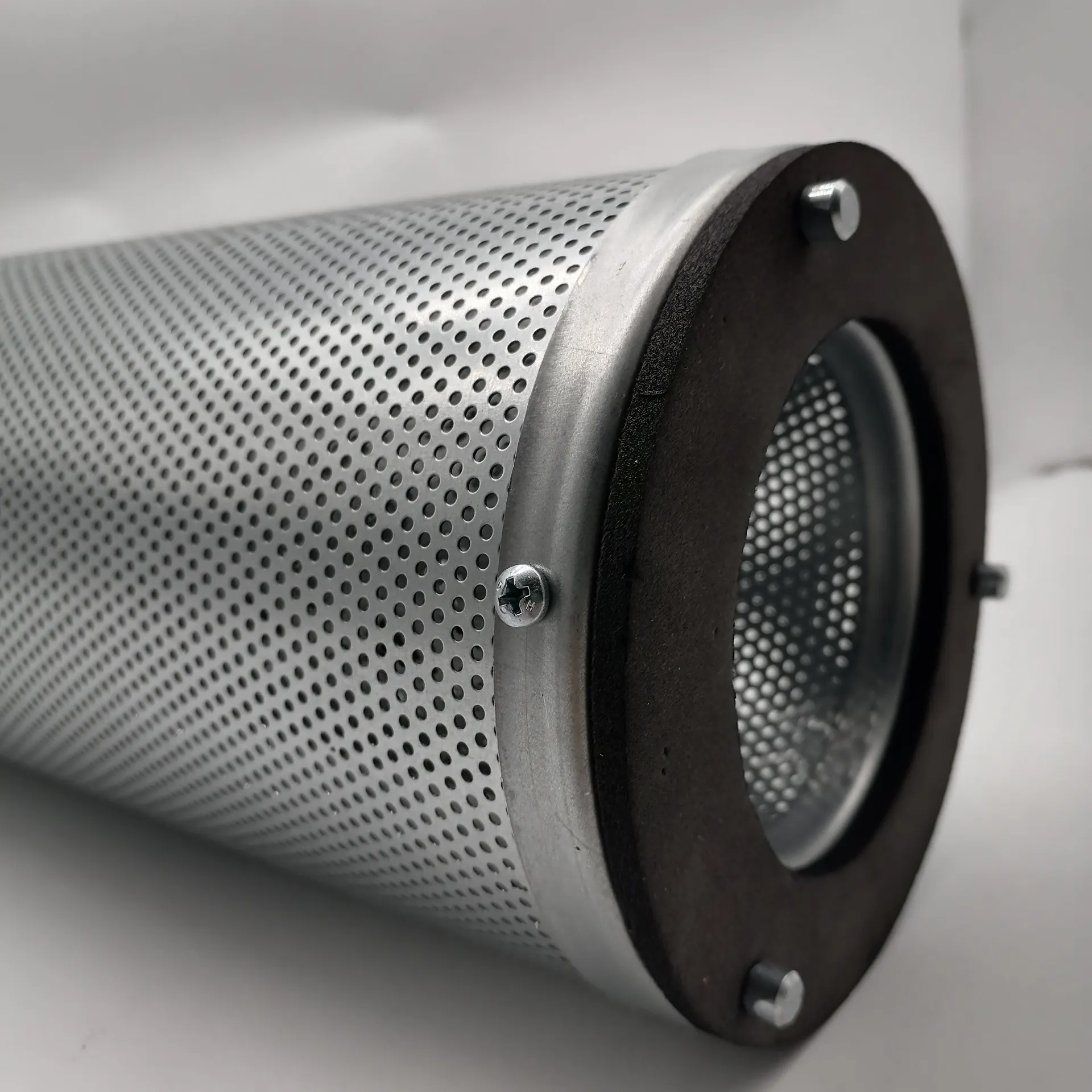

heavy equipment air filter

When navigating the complex landscape of heavy equipment maintenance, one component often emerges as a silent yet paramount player the air filter. Heavy equipment air filters are not just accessories; they are linchpins in ensuring optimal performance, extending lifespan, and reducing costly downtimes of machinery used in industries ranging from construction to mining. This narrative draws on years of experience in the field, providing a lens into why selecting the right air filter isn't merely a purchase but a strategic decision.

Maintenance plays a critical role in the lifecycle of heavy equipment air filters. Regular inspections are necessary to detect signs of damage or blockages that could impede performance. Experienced maintenance engineer Sarah Lin emphasizes the significance of routine checks “Preventative maintenance extends the life of the filter and, by extension, the machinery. It’s not just about avoiding breakdowns; it’s about sustaining peak operational performance.” Given the financial stakes, trustworthiness in the air filter market is paramount. It's essential to steer clear of counterfeit or substandard filters, which, while initially cheaper, can lead to costly engine repairs or replacements in the long run. Verifying the source is indispensable, ensuring that all purchases come from authorized dealers or directly from the manufacturer. The advancement of technology in air filtration solutions provides additional layers of assurance. Some of the cutting-edge features include nano-fiber technology, which captures smaller particulates without compromising airflow; and integrated sensors, which alert operators when a filter needs replacement. Such innovations not only enhance the performance of heavy equipment but also reduce environmental impact by optimizing engine efficiency and reducing emissions. Investing in the right heavy equipment air filter is an investment in the machinery's future—a standpoint supported by industry experts and evidenced by countless field experiences. The impact of choosing the correct air filter ripples through every aspect of heavy machinery operation, from cost-efficiency and longevity to environmental responsibility. Through informed decision-making and the selection of reputable providers, businesses can cultivate trustworthiness and authority in the operational efficacy of their heavy equipment fleets.

Maintenance plays a critical role in the lifecycle of heavy equipment air filters. Regular inspections are necessary to detect signs of damage or blockages that could impede performance. Experienced maintenance engineer Sarah Lin emphasizes the significance of routine checks “Preventative maintenance extends the life of the filter and, by extension, the machinery. It’s not just about avoiding breakdowns; it’s about sustaining peak operational performance.” Given the financial stakes, trustworthiness in the air filter market is paramount. It's essential to steer clear of counterfeit or substandard filters, which, while initially cheaper, can lead to costly engine repairs or replacements in the long run. Verifying the source is indispensable, ensuring that all purchases come from authorized dealers or directly from the manufacturer. The advancement of technology in air filtration solutions provides additional layers of assurance. Some of the cutting-edge features include nano-fiber technology, which captures smaller particulates without compromising airflow; and integrated sensors, which alert operators when a filter needs replacement. Such innovations not only enhance the performance of heavy equipment but also reduce environmental impact by optimizing engine efficiency and reducing emissions. Investing in the right heavy equipment air filter is an investment in the machinery's future—a standpoint supported by industry experts and evidenced by countless field experiences. The impact of choosing the correct air filter ripples through every aspect of heavy machinery operation, from cost-efficiency and longevity to environmental responsibility. Through informed decision-making and the selection of reputable providers, businesses can cultivate trustworthiness and authority in the operational efficacy of their heavy equipment fleets.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: