ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

1 月 . 30, 2025 05:47 Back to list

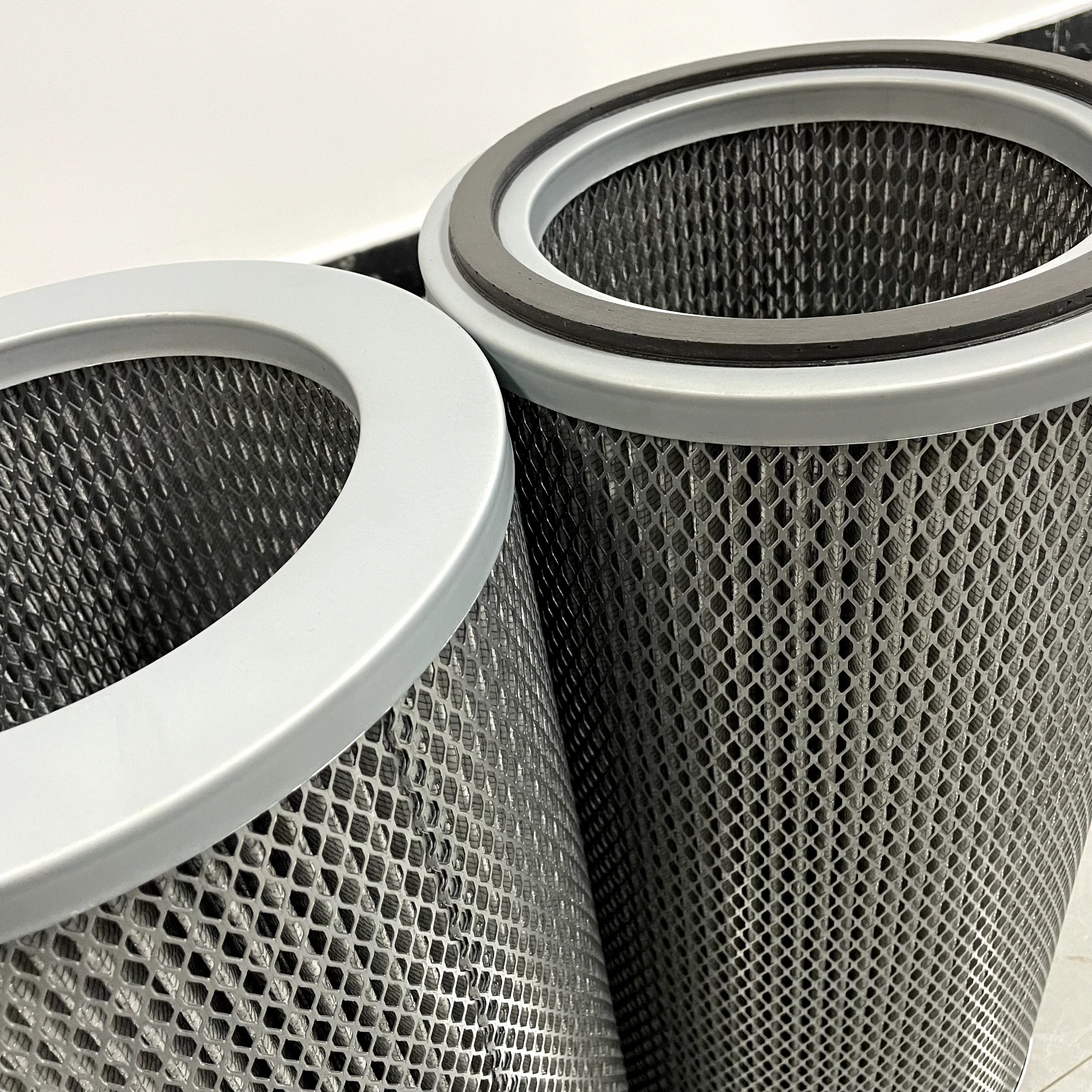

Low cost durable air filter for gas turbine

Gas turbine inlet filters play a crucial role in ensuring the efficient operation of gas turbines by purifying the air that enters the system. For industries reliant on gas turbines, the proper selection and maintenance of these filters are paramount to maximizing performance, reducing maintenance costs, and extending the lifespan of the turbine. This article delves into the nuances of gas turbine inlet filters, combining practical experience with expert insights to offer a uniquely authoritative perspective.

Furthermore, the credibility of a filter manufacturer is often gauged by their adherence to international standards, such as ISO 16890 or ASHRAE standards. Industry experts accentuate that compliance with these standards is not merely regulatory but serves as a trust benchmark from which consumers can confidently ascertain filter efficacy. A manufacturer's commitment to these benchmarks, alongside transparent customer service and robust warranty policies, enhances trustworthiness, fostering a long-term partnership between suppliers and users. In addition to selecting the right filter, field experiences underscore the importance of employing trained personnel to manage installation and maintenance. Improper handling can lead to compromised filter integrity, subsequently affecting the overall turbine operation. It remains a best practice for businesses to engage with manufacturers who provide comprehensive training programs, ensuring that operation staff possess the technical expertise necessary for effective filter management. In conclusion, the intricate dynamics of gas turbine inlet filters reflect their indispensable role in industrial operations. From selecting the appropriate filter type to engaging in rigorous maintenance protocols, each step benefits from a blend of experience, expertise, authority, and credibility. As industries continue to prioritize efficiency, sustainability, and cost-effectiveness, the sophisticated solutions offered by advanced filter technologies stand at the forefront, shaping the future of industrial energy consumption.

Furthermore, the credibility of a filter manufacturer is often gauged by their adherence to international standards, such as ISO 16890 or ASHRAE standards. Industry experts accentuate that compliance with these standards is not merely regulatory but serves as a trust benchmark from which consumers can confidently ascertain filter efficacy. A manufacturer's commitment to these benchmarks, alongside transparent customer service and robust warranty policies, enhances trustworthiness, fostering a long-term partnership between suppliers and users. In addition to selecting the right filter, field experiences underscore the importance of employing trained personnel to manage installation and maintenance. Improper handling can lead to compromised filter integrity, subsequently affecting the overall turbine operation. It remains a best practice for businesses to engage with manufacturers who provide comprehensive training programs, ensuring that operation staff possess the technical expertise necessary for effective filter management. In conclusion, the intricate dynamics of gas turbine inlet filters reflect their indispensable role in industrial operations. From selecting the appropriate filter type to engaging in rigorous maintenance protocols, each step benefits from a blend of experience, expertise, authority, and credibility. As industries continue to prioritize efficiency, sustainability, and cost-effectiveness, the sophisticated solutions offered by advanced filter technologies stand at the forefront, shaping the future of industrial energy consumption.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: