Tel:

+8618931101301

Tel:

+8618931101301

12 月 . 04, 2024 09:31 Back to list

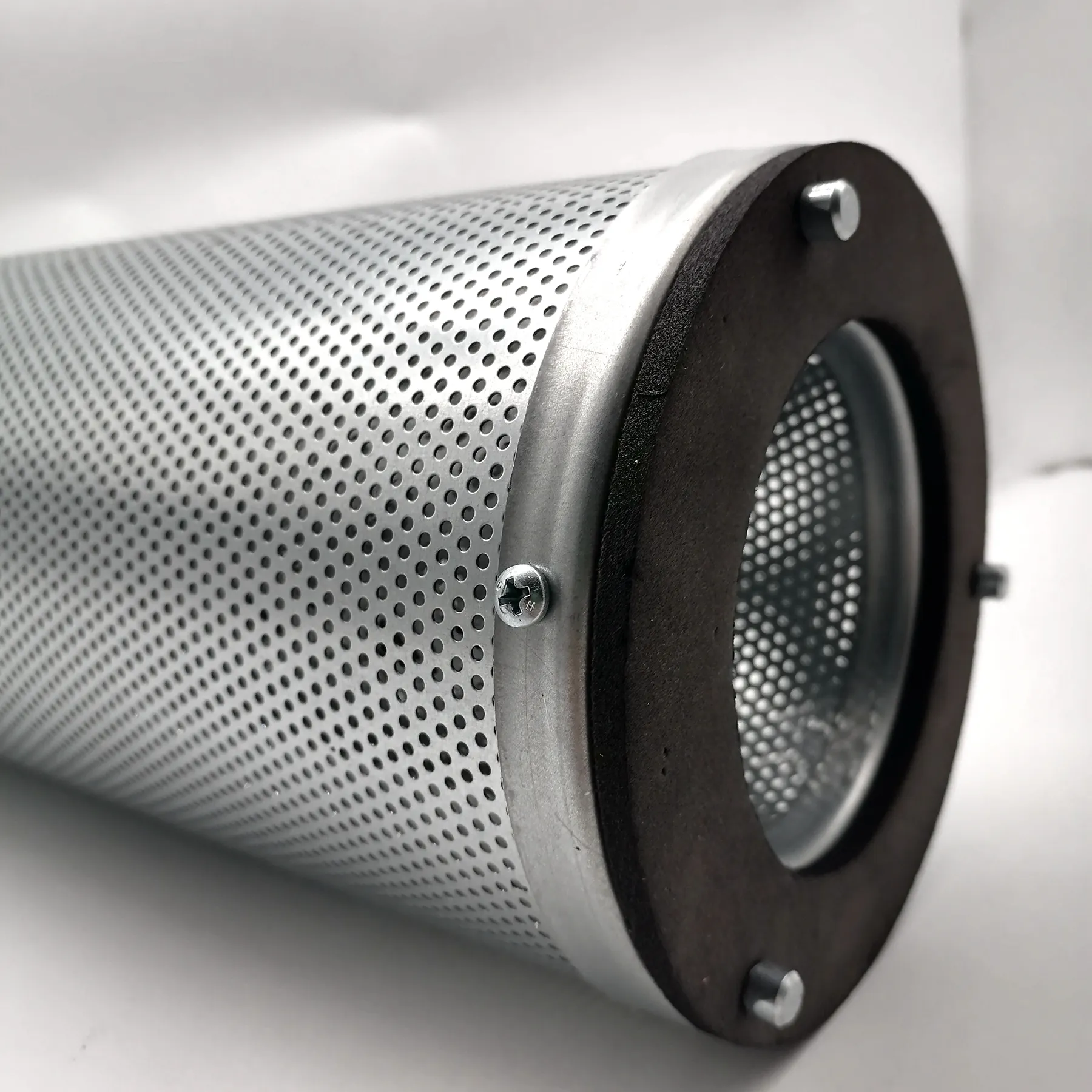

gas turbine inlet filter

Gas Turbine Inlet Filters Essential Quality for Optimal Performance

Gas turbines are at the heart of modern power generation and aviation industries, offering high efficiency and reliability. However, their performance can be significantly affected by various environmental factors, primarily the quality of the air entering the turbine. This is where gas turbine inlet filters play a crucial role. These filters are designed to protect the gas turbine from particulates, contaminants, and other airborne pollutants that can impair efficiency and reduce operational lifespan.

Importance of Inlet Filtering

The primary purpose of inlet filters is to ensure that the air entering the gas turbine is as clean as possible. Contaminants such as dust, pollen, salt, and industrial debris can lead to several issues, including erosion, fouling, and corrosion within the turbine. These problems not only affect the turbine’s performance but can also result in costly downtime and increased maintenance needs. By using effective inlet filters, operators can minimize these risks, thus optimizing the operational reach and lifespan of their gas turbines.

Types of Inlet Filters

Inlet filters come in various configurations and types to meet different needs and environmental conditions. The two primary categories are

1. Dry Filters These use a fibrous medium to trap particles. They are typically made from materials such as glass fiber or synthetic media and are effective for small to moderate particle sizes. Dry filters are commonly used in environments where humidity is not a concern.

2. Wet Filters (or Mist Eliminators) These filters use water or oil to capture and retain contaminants. They are especially useful in coastal areas or locations with high humidity, where salt and moisture can become significant concerns. By capturing these contaminants, wet filters help to prevent erosion and damage to turbine components.

gas turbine inlet filter

Filter Efficiency and Performance

The performance of an inlet filter is measured by its efficiency in capturing particles. The MERV (Minimum Efficiency Reporting Value) rating system is often used to evaluate the effectiveness of air filters. Higher MERV ratings indicate better filtration capability, capturing smaller particles. For gas turbine applications, filters with MERV ratings of 14 or higher are typically recommended. However, one must strike a balance between filtration efficiency and airflow resistance. High-efficiency filters can restrict air intake, leading to reduced turbine performance.

Maintenance and Monitoring

Regular maintenance and monitoring are essential for optimal filter performance. Operators should implement a regular inspection and replacement schedule based on the specific operating environment and the type of filtering system in place. Monitoring tools such as pressure sensors can help determine when a filter needs cleaning or replacement, ensuring minimal disruption in turbine operation. Proper maintenance not only extends the life of the filters but also enhances the overall efficiency and reliability of the gas turbines.

Advances in Inlet Filtration Technology

Recent advancements in filter technology have led to the development of more efficient and durable inlet filters. Innovations such as nanofiber technology promise improved filtration capabilities while maintaining low airflow resistance. Additionally, smart filter systems equipped with IoT (Internet of Things) capabilities allow for real-time monitoring and data analysis, providing operators with crucial information on air quality and filter performance.

Conclusion

In conclusion, gas turbine inlet filters are a critical component in the operation and maintenance of gas turbines, ensuring clean air intake and protecting against environmental contaminants. By selecting the appropriate type of filter, maintaining it properly, and staying informed about technological advancements, operators can significantly enhance the performance and longevity of their gas turbines. As the demand for clean and efficient energy continues to grow, the importance of robust inlet filtration systems will only increase, reinforcing their role as an essential element in the operation of gas turbines.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: