ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 16, 2025 00:48 Back to list

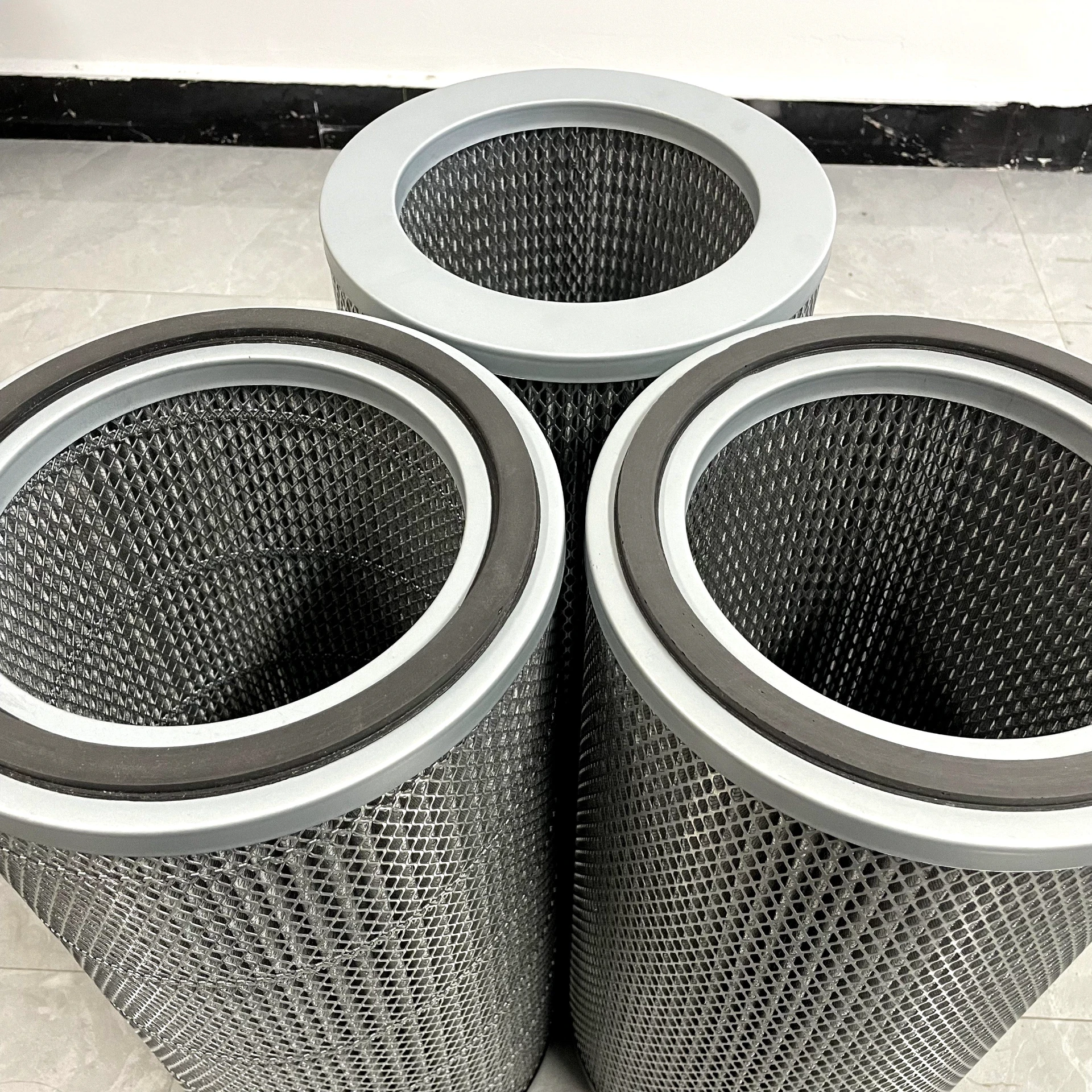

Low cost durable air filter for gas turbine

Gas turbine filter media play a crucial role in the efficient operation of gas turbines, impacting everything from performance to longevity. Understanding these filter media's intricacies involves delving into their materials, applications, and benefits, ensuring your turbine maintains optimal operational efficiency.

The expertise required to navigate the landscape of gas turbine filter media must not only be technical but also encompass a strategic understanding of operational needs and goals. Consulting with manufacturers that specialize in filtration solutions can provide invaluable insights into which media suits specific operational environments. Their expertise ensures that the chosen filter media aligns with both the technical specifications of the turbines and the financial expectations of the stakeholders involved. Authoritativeness in this sphere comes from drawing on both empirical data and real-world case studies that highlight successful implementations of specific filter technologies. Analyzing these case studies offers a tangible benchmark for performance metrics, supporting informed decision-making processes regarding filter media selection. It is through these insights that organizations can appreciate the impact of incremental adjustments and technological upgrades on the overall lifecycle performance of their gas turbines. Last but not least is trustworthiness, rooted in the transparent communication of a filter's capabilities and limitations. Manufacturers and suppliers should readily provide detailed specifications, testing certifications, and performance data, fostering confidence in the media's ability to meet operational demands. Reliability in information builds trust, which is paramount in industries where precision and performance cannot be compromised. In conclusion, the role of gas turbine filter media extends beyond mere maintenance of operational efficiency; it encompasses strategic efficiencies and significant financial advantages. From material selection to operational considerations, and from expert consultation to authoritative insight, the investment in high-quality filter media proves its value in reliability and cost-efficiency. Such meticulous attention to fiber choice and deployment can indeed be a game-changer for gas turbine operation and sustainability.

The expertise required to navigate the landscape of gas turbine filter media must not only be technical but also encompass a strategic understanding of operational needs and goals. Consulting with manufacturers that specialize in filtration solutions can provide invaluable insights into which media suits specific operational environments. Their expertise ensures that the chosen filter media aligns with both the technical specifications of the turbines and the financial expectations of the stakeholders involved. Authoritativeness in this sphere comes from drawing on both empirical data and real-world case studies that highlight successful implementations of specific filter technologies. Analyzing these case studies offers a tangible benchmark for performance metrics, supporting informed decision-making processes regarding filter media selection. It is through these insights that organizations can appreciate the impact of incremental adjustments and technological upgrades on the overall lifecycle performance of their gas turbines. Last but not least is trustworthiness, rooted in the transparent communication of a filter's capabilities and limitations. Manufacturers and suppliers should readily provide detailed specifications, testing certifications, and performance data, fostering confidence in the media's ability to meet operational demands. Reliability in information builds trust, which is paramount in industries where precision and performance cannot be compromised. In conclusion, the role of gas turbine filter media extends beyond mere maintenance of operational efficiency; it encompasses strategic efficiencies and significant financial advantages. From material selection to operational considerations, and from expert consultation to authoritative insight, the investment in high-quality filter media proves its value in reliability and cost-efficiency. Such meticulous attention to fiber choice and deployment can indeed be a game-changer for gas turbine operation and sustainability.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: