ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

1 月 . 15, 2025 09:39 Back to list

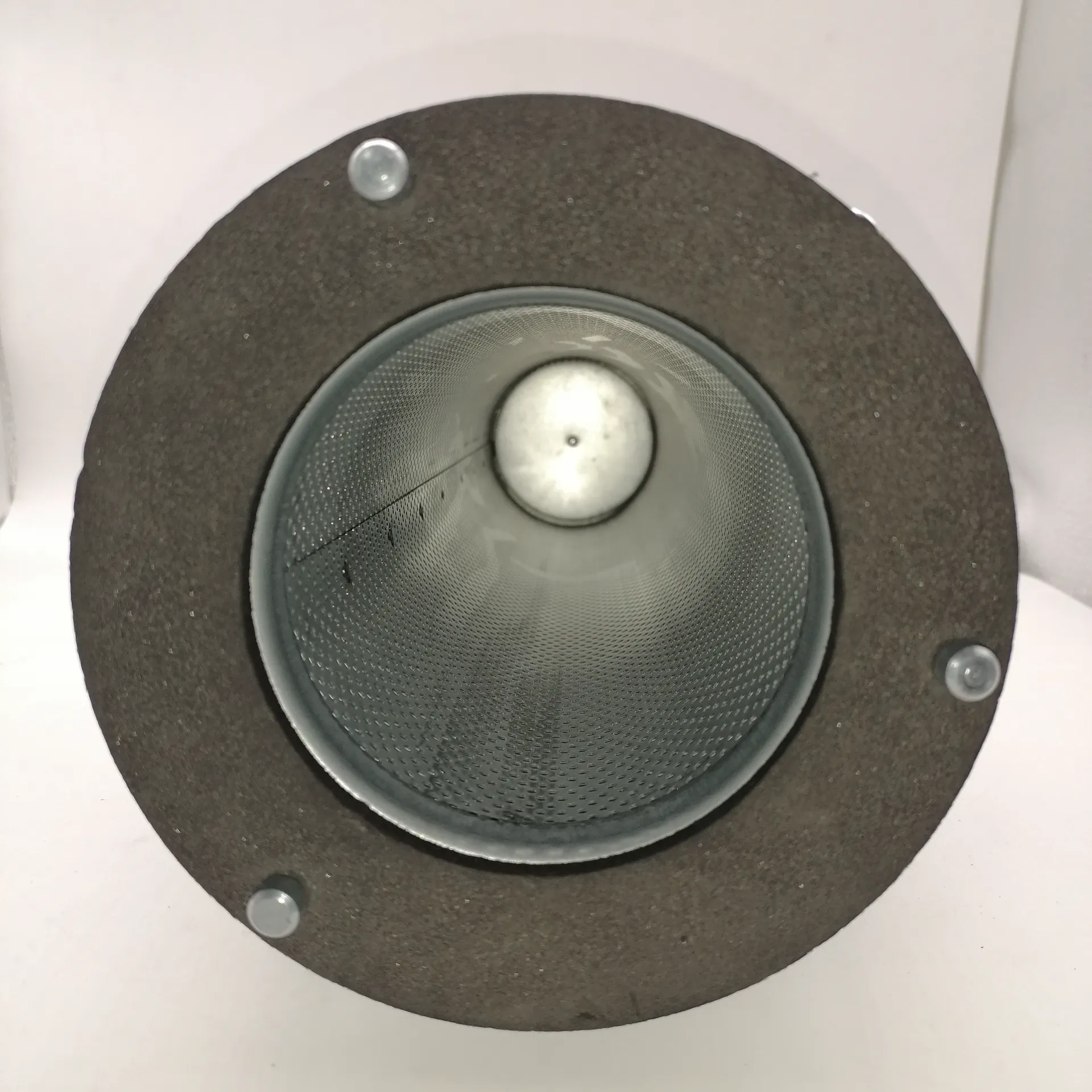

Low cost durable air filter for gas turbine

Gas turbines are marvels of modern engineering, central to many industrial applications, from power generation to oil and gas processing. At the heart of maintaining these massive machines' efficiency is the gas turbine filter. Selecting the optimal filter is imperative, not only to enhance performance but also to extend the turbine's lifespan.

Trustworthiness in product selection is equally paramount. Choosing filters from well-established manufacturers that have a proven track record in the field is vital. Brands like Camfil, Mann+Hummel, and Donaldson have built their reputations through years of rigorous testing and field success—factors which greatly aid in establishing confidence in their products' reliability. Reviews and case studies often provide the necessary verification that these filters have been peer-tested in similar operational conditions. Besides selection, maintenance is another cornerstone of ensuring filters provide optimal benefits. Regular inspections and timely replacements not only maintain peak turbine performance but can also prevent costly downtimes. Experience shows that neglecting filter maintenance can lead to severe performance drops and eventually necessitate more extensive turbine repairs. In conclusion, the role of gas turbine filters extends far beyond a basic maintenance component. They are fundamental to the operational success and cost management of any industrial facility relying on gas turbines. In selecting and maintaining these filters, an experience-driven, expert approach that emphasizes authoritative sources and trustworthy products is crucial in achieving sustainable turbine operation and optimal performance.

Trustworthiness in product selection is equally paramount. Choosing filters from well-established manufacturers that have a proven track record in the field is vital. Brands like Camfil, Mann+Hummel, and Donaldson have built their reputations through years of rigorous testing and field success—factors which greatly aid in establishing confidence in their products' reliability. Reviews and case studies often provide the necessary verification that these filters have been peer-tested in similar operational conditions. Besides selection, maintenance is another cornerstone of ensuring filters provide optimal benefits. Regular inspections and timely replacements not only maintain peak turbine performance but can also prevent costly downtimes. Experience shows that neglecting filter maintenance can lead to severe performance drops and eventually necessitate more extensive turbine repairs. In conclusion, the role of gas turbine filters extends far beyond a basic maintenance component. They are fundamental to the operational success and cost management of any industrial facility relying on gas turbines. In selecting and maintaining these filters, an experience-driven, expert approach that emphasizes authoritative sources and trustworthy products is crucial in achieving sustainable turbine operation and optimal performance.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: