ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 15, 2025 06:59 Back to list

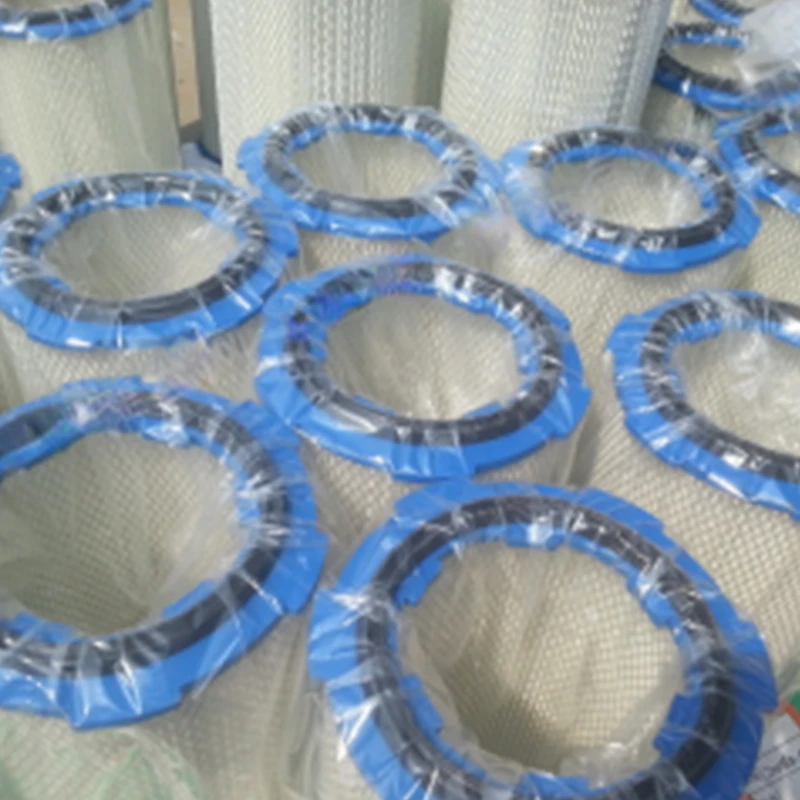

Gas Turbine Intake Filter

In the intricate world of industrial machinery, the role of gas turbine air intake filter manufacturers is often understated yet critically vital. These manufacturers not only play a fundamental part in ensuring the optimal performance of gas turbines but also in preserving the longevity and efficiency of entire power plants and aviation engines. With decades of experience under their belts, they continue to drive innovation in filtration technology, setting new standards for quality and reliability in their products.

Furthermore, these manufacturers invest heavily in research and development to stay ahead of evolving environmental challenges. Whether it’s tailoring solutions for increasingly stringent emission standards or developing filters with improved resistance to harsh environmental conditions, their commitment to innovation and adaptability speaks volumes about their enduring authority in the field. Regarding trustworthiness, customer relationships are at the forefront. Manufacturers who consistently deliver on quality promises build long-lasting partnerships with major power generation companies and aerospace firms. They often provide comprehensive support, from installation to maintenance, ensuring that their filters operate optimally throughout their lifecycle. In doing so, they garner the trust and loyalty of their clients, who recognize the value in dedicated customer service and technical support. User testimonials and case studies are invaluable in this regard, highlighting real-world successes where high-quality intake filters have dramatically improved turbine performance and reliability. These insights not only reflect the tangible benefits of leveraging superior filtration solutions but also the manufacturers' dedication to exceeding customer expectations. In conclusion, gas turbine air intake filter manufacturers are pivotal stakeholders in the maintenance and optimization of turbine operations. With robust expertise, substantial authority in the industry, and a steadfast commitment to innovation and customer satisfaction, they continue to enhance the sustainability and efficiency of machinery in various sectors. Their work not only supports the demands of today’s industrial landscape but also anticipates the challenges of tomorrow, making them an indispensable part of the power and aviation sectors.

Furthermore, these manufacturers invest heavily in research and development to stay ahead of evolving environmental challenges. Whether it’s tailoring solutions for increasingly stringent emission standards or developing filters with improved resistance to harsh environmental conditions, their commitment to innovation and adaptability speaks volumes about their enduring authority in the field. Regarding trustworthiness, customer relationships are at the forefront. Manufacturers who consistently deliver on quality promises build long-lasting partnerships with major power generation companies and aerospace firms. They often provide comprehensive support, from installation to maintenance, ensuring that their filters operate optimally throughout their lifecycle. In doing so, they garner the trust and loyalty of their clients, who recognize the value in dedicated customer service and technical support. User testimonials and case studies are invaluable in this regard, highlighting real-world successes where high-quality intake filters have dramatically improved turbine performance and reliability. These insights not only reflect the tangible benefits of leveraging superior filtration solutions but also the manufacturers' dedication to exceeding customer expectations. In conclusion, gas turbine air intake filter manufacturers are pivotal stakeholders in the maintenance and optimization of turbine operations. With robust expertise, substantial authority in the industry, and a steadfast commitment to innovation and customer satisfaction, they continue to enhance the sustainability and efficiency of machinery in various sectors. Their work not only supports the demands of today’s industrial landscape but also anticipates the challenges of tomorrow, making them an indispensable part of the power and aviation sectors.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: