ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 13, 2025 20:57 Back to list

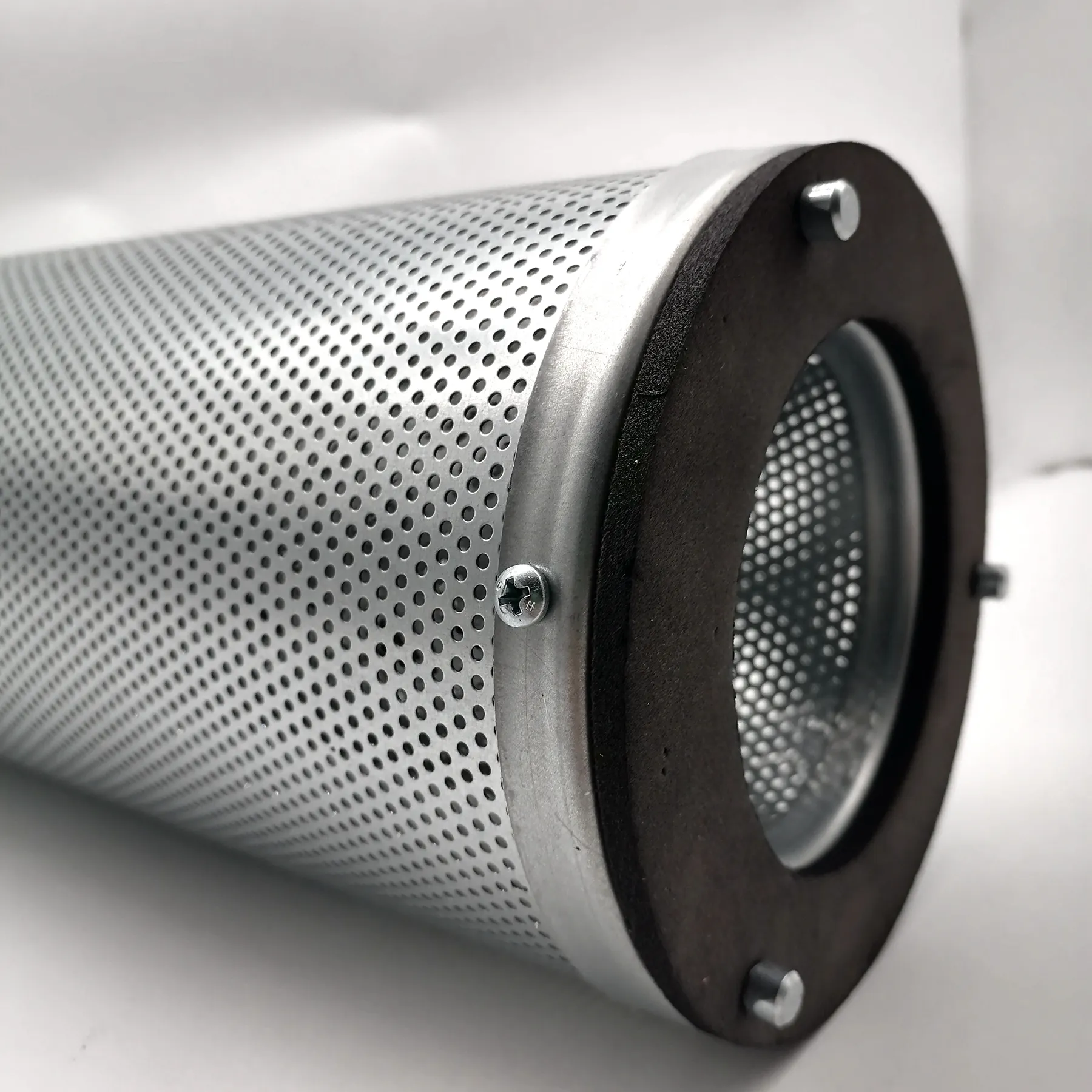

Gas Turbine Intake Filter

Designing a high-efficiency air intake filter system for gas turbines is a critical facet of ensuring optimal performance and longevity. A well-engineered filter not only enhances performance but also protects the turbine from harmful particulates and environmental contaminants. This article offers an in-depth exploration of the key elements that form the bedrock of a superior gas turbine air intake filter design, grounded in the principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T).

Trustworthiness in filter design is often achieved through rigorous testing and compliance with international standards. Filters should undergo comprehensive testing, including efficiency tests for various particulate sizes, pressure drop assessments, and environmental simulations to evaluate performance under different conditions. Adhering to standards like ASME, ISO, and other regional regulations instills confidence in the product’s capability and reliability. Incorporating user feedback into the design process fortifies trustworthiness, providing real-world validation of the filter’s performance. Field testing with transparency in results can highlight areas of improvement or confirm the efficacy of the design, offering customers peace of mind that their gas turbine will operate efficiently and with minimal risk of failure. Finally, addressing the ease of maintenance is essential for a practical design. An ideal filter system should allow for easy access, inspection, and replacement of filter elements. Modular designs are particularly advantageous, providing scalability and simple upgrades as needed, without the requirement for extensive downtime or technical expertise. In conclusion, the synthesis of experience, expertise, authoritativeness, and trustworthiness forms the backbone of an exemplary gas turbine air intake filter design. By focusing on material selection, innovative technology, rigorous testing, and user-centric design choices, manufacturers can develop filters that not only meet but exceed industry standards, ensuring robust performance, reliability, and customer satisfaction. As the industry continues to evolve, there remains a steadfast commitment to pushing the boundaries of innovation in filter design, underpinned by a foundation of proven principles and a forward-thinking approach.

Trustworthiness in filter design is often achieved through rigorous testing and compliance with international standards. Filters should undergo comprehensive testing, including efficiency tests for various particulate sizes, pressure drop assessments, and environmental simulations to evaluate performance under different conditions. Adhering to standards like ASME, ISO, and other regional regulations instills confidence in the product’s capability and reliability. Incorporating user feedback into the design process fortifies trustworthiness, providing real-world validation of the filter’s performance. Field testing with transparency in results can highlight areas of improvement or confirm the efficacy of the design, offering customers peace of mind that their gas turbine will operate efficiently and with minimal risk of failure. Finally, addressing the ease of maintenance is essential for a practical design. An ideal filter system should allow for easy access, inspection, and replacement of filter elements. Modular designs are particularly advantageous, providing scalability and simple upgrades as needed, without the requirement for extensive downtime or technical expertise. In conclusion, the synthesis of experience, expertise, authoritativeness, and trustworthiness forms the backbone of an exemplary gas turbine air intake filter design. By focusing on material selection, innovative technology, rigorous testing, and user-centric design choices, manufacturers can develop filters that not only meet but exceed industry standards, ensuring robust performance, reliability, and customer satisfaction. As the industry continues to evolve, there remains a steadfast commitment to pushing the boundaries of innovation in filter design, underpinned by a foundation of proven principles and a forward-thinking approach.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: