ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 10, 2025 12:16 Back to list

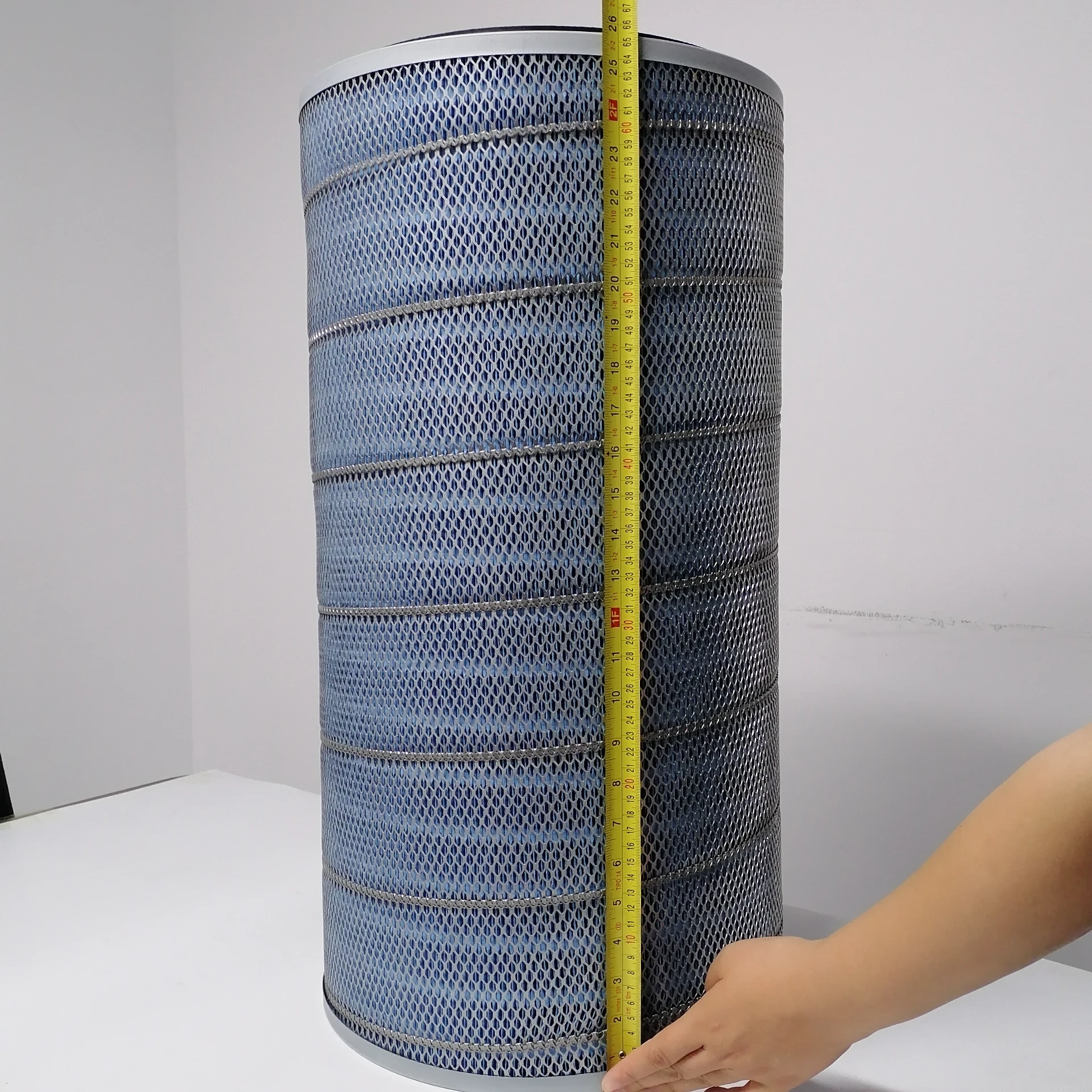

Gas Turbine Intake Filter

Designing air intake filters for gas turbines involves a highly specialized process that plays a critical role in the overall efficiency and longevity of the turbine. As industrial demand for energy grows, optimizing the components that protect these complex machines becomes essential. This article provides insight into effective air intake filter design, emphasizing real-world experience, expert knowledge, and credibility in the field.

From an architectural perspective, the integration of the air intake system with the turbine also requires rigorous attention. The aerodynamic design, including the shape and alignment of ducts and baffles, significantly affects the efficiency of the air intake system. Experienced designers understand that reducing turbulence and ensuring a steady airflow path can lead to more stable turbine performance. Therefore, advanced computational fluid dynamics (CFD) tools are frequently employed to model and refine these aspects of the design, ensuring the intake system aligns perfectly with the turbine’s operational demands. The importance of compliance with industry standards and regulations cannot be overstated. Air intake filters often need to meet stringent criteria established by organizations such as the International Organization for Standardization (ISO) or the American Society of Mechanical Engineers (ASME). Compliance not only assures performance integrity but also builds trust and confidence among stakeholders. Thereby, it is essential that design teams keep abreast of the latest standards and integrate them into their design and testing processes. Enhancing trustworthiness means demonstrating the proven capabilities of the filter design through field trials and empirical data. Publishing case studies of installations that meet or exceed customer expectations provides concrete evidence of a design's success. Such transparency fosters confidence in potential clients or stakeholders evaluating various air intake solutions. In conclusion, the design of air intake filters for gas turbines is a multi-dimensional challenge, blending engineering excellence with practical insights. By focusing on environmental adaptability, balancing efficiency with system pressure, ensuring ease of maintenance, harmonizing with the turbine architecture, adhering to international standards, and substantiating with real-world data, designers can profoundly influence turbine performance and reliability. The ultimate measure of success is not just in theoretical promise but in demonstrated, reliable performance in diverse operational contexts.

From an architectural perspective, the integration of the air intake system with the turbine also requires rigorous attention. The aerodynamic design, including the shape and alignment of ducts and baffles, significantly affects the efficiency of the air intake system. Experienced designers understand that reducing turbulence and ensuring a steady airflow path can lead to more stable turbine performance. Therefore, advanced computational fluid dynamics (CFD) tools are frequently employed to model and refine these aspects of the design, ensuring the intake system aligns perfectly with the turbine’s operational demands. The importance of compliance with industry standards and regulations cannot be overstated. Air intake filters often need to meet stringent criteria established by organizations such as the International Organization for Standardization (ISO) or the American Society of Mechanical Engineers (ASME). Compliance not only assures performance integrity but also builds trust and confidence among stakeholders. Thereby, it is essential that design teams keep abreast of the latest standards and integrate them into their design and testing processes. Enhancing trustworthiness means demonstrating the proven capabilities of the filter design through field trials and empirical data. Publishing case studies of installations that meet or exceed customer expectations provides concrete evidence of a design's success. Such transparency fosters confidence in potential clients or stakeholders evaluating various air intake solutions. In conclusion, the design of air intake filters for gas turbines is a multi-dimensional challenge, blending engineering excellence with practical insights. By focusing on environmental adaptability, balancing efficiency with system pressure, ensuring ease of maintenance, harmonizing with the turbine architecture, adhering to international standards, and substantiating with real-world data, designers can profoundly influence turbine performance and reliability. The ultimate measure of success is not just in theoretical promise but in demonstrated, reliable performance in diverse operational contexts.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: