Tel:

+8618931101301

Tel:

+8618931101301

12 月 . 04, 2024 10:11 Back to list

gas turbine air intake filter design

Gas Turbine Air Intake Filter Design

The design of air intake filters for gas turbines is a crucial aspect that directly influences the operational efficiency, longevity, and reliability of these engines. Gas turbines are widely employed in various industries such as power generation, aviation, and marine applications. The air intake system must ensure that only clean air enters the turbine, as impurities can lead to increased maintenance costs, reduced performance, and unscheduled downtime.

Importance of Air Intake Filters

Air quality is vital for the optimal performance of gas turbines. These engines operate at high temperatures and pressures, meaning that even a small amount of contaminants in the intake air can have significant adverse effects. Particulate matter, such as dust, dirt, and other airborne pollutants, can cause erosion of turbine blades, degrading their aerodynamic efficiency. Additionally, contaminants can lead to fouling of the compressor sections and increased corrosion in the combustion chamber, resulting in performance losses and shortened service life.

Design Considerations

When designing air intake filters for gas turbines, several key factors must be taken into account

1. Filtration Efficiency The primary goal of an air intake filter is to efficiently remove contaminants from the air. The design must balance filtration efficiency with airflow resistance. High-efficiency filters that capture small particles without significantly impeding airflow are essential for maintaining turbine performance.

2. Dust Load Capacity Gas turbine environments can vary widely, particularly in industrial applications. Filters must be designed to handle varying levels of dust load without frequent replacements. This involves selecting appropriate materials and designs that can accommodate high particulate concentrations.

3. Pressure Drop Every air intake filter introduces a pressure drop which can adversely affect engine performance. Filters must be designed to minimize this drop while still maintaining high filtration efficiency. A low-pressure drop means that the turbine does not have to work as hard to draw in air, improving overall fuel efficiency.

4. Temperature and Humidity Resistance Operating conditions for gas turbines can involve wide temperature ranges and high humidity levels. Filters must be constructed from materials that can withstand these environmental stresses without degrading over time.

gas turbine air intake filter design

5. Maintenance and Accessibility Ease of maintenance is another critical factor. Filters should be designed for easy replacement and cleaning to minimize downtime and associated costs. Design considerations may include modular filter elements or systems that allow for in-situ maintenance.

6. Regulatory Compliance Many industries are subject to strict environmental regulations regarding air quality. Thus, filter designs must comply with relevant standards to ensure that they effectively reduce environmental impacts.

Types of Filters

Various types of filters are used in gas turbine air intake systems, including

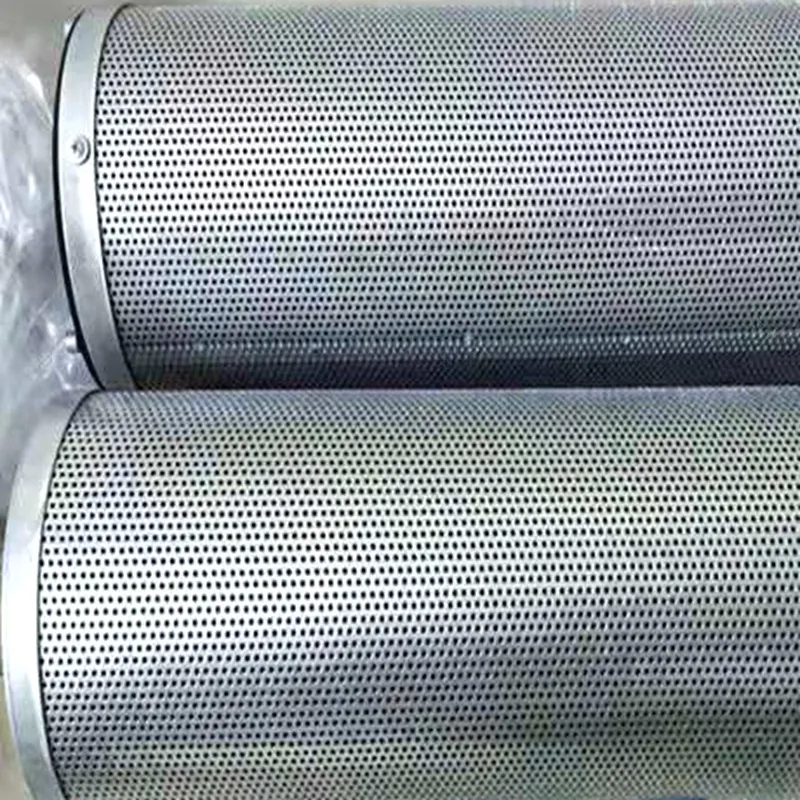

- Mechanical Filters These filters physically remove particulates from the air and are often made from synthetic or fiberglass materials. They offer a good balance between filtration efficiency and airflow resistance.

- Electrostatic Filters Utilizing electrostatic charges to attract particles, these filters can be highly efficient but may require regular maintenance to maintain their effectiveness.

- Wet Washable Filters These filters can be cleaned with water or other fluids, making them cost-effective in certain applications where dust loads are consistently high.

Conclusion

The design of air intake filters for gas turbines is a multifaceted challenge that requires careful consideration of many factors, including filtration efficiency, dust load capacity, pressure drop, and maintenance needs. Effective filtration not only enhances turbine performance but also significantly impacts operational costs and environmental compliance. As technology advances, innovations in filter design will continue to improve the efficiency and reliability of gas turbines, making them an essential component of modern energy generation and transportation systems. Ultimately, investing in a well-designed air intake filtration system pays dividends in terms of reduced maintenance, increased efficiency, and extended equipment life.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: