ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

3 月 . 05, 2025 01:00 Back to list

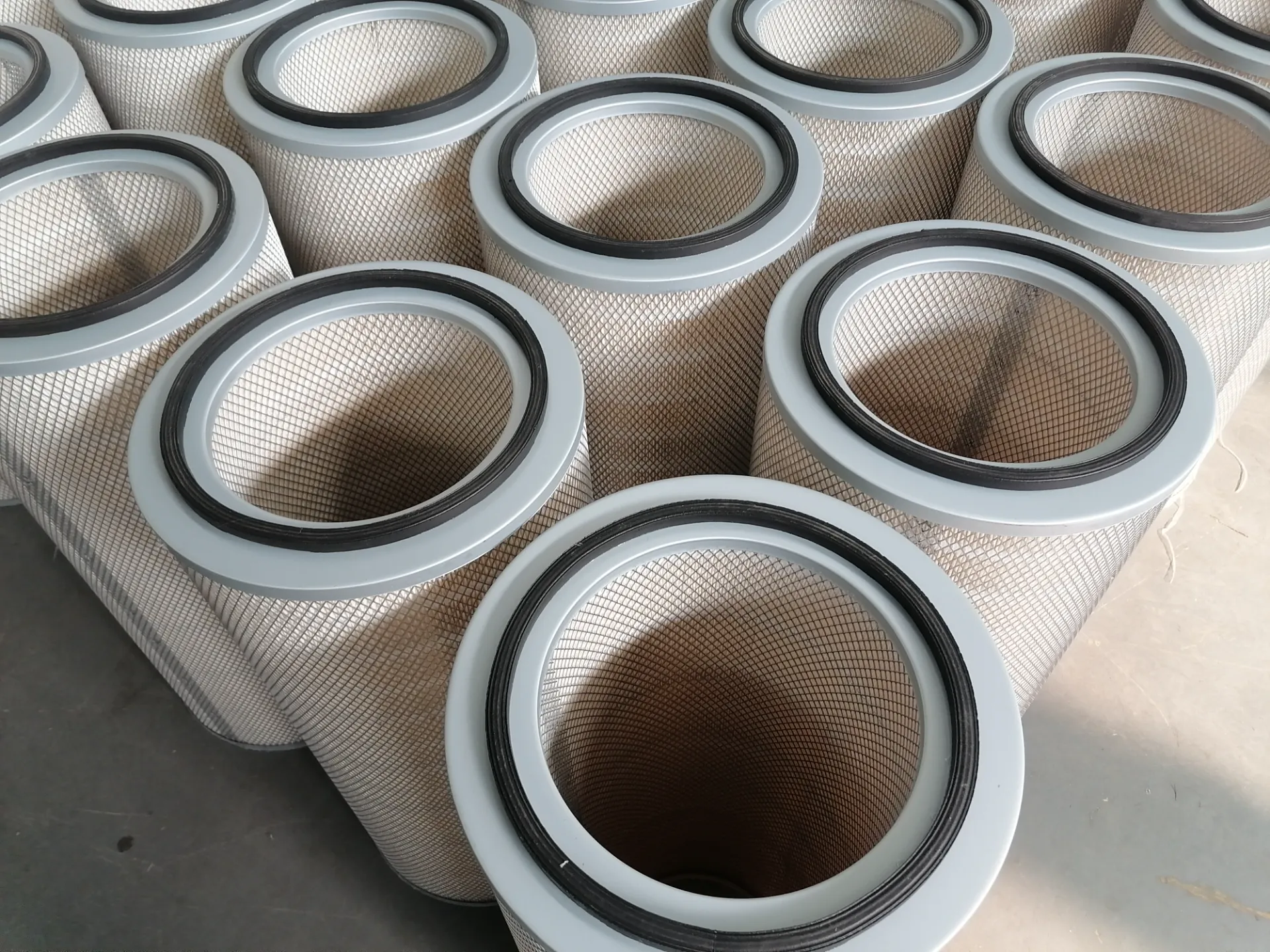

gas turbine air intake filter

Selecting the right air intake filter for a gas turbine is crucial to the efficiency and longevity of the equipment. These power-generating engines rely on the purity of the air that feeds them, impacting not only performance but also maintenance intervals and operational costs. As experts in the field of energy production machinery, we understand the necessity of filtering systems that not only meet but exceed industry standards.

When selecting an intake filter, operators should rely heavily on systems that have been independently tested and verified. Industry certifications, such as those by ISO (International Organization for Standardization) or ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers), serve as benchmarks for performance reliability and trustworthiness. Certified filters have undergone rigorous evaluations to ensure they meet specific performance standards that safeguard the turbine's operational integrity. Long-term cost efficiency is another critical consideration. While more advanced filters may come with a higher initial price tag, the cost-benefit analysis often reveals savings in reduced downtime, less frequent maintenance, and extended machinery life. Collaborating with manufacturers that provide comprehensive data sheets, performance analytics, and customer testimonials can ensure confidence in the filter’s long-term efficacy. Finally, end-users must prioritize working with manufacturers and suppliers that offer robust after-sales support and technical assistance. Establishing a partnership with a reputable company that stands behind its products with warranties, support services, and expert advice is invaluable. Such alliances ensure any issues are promptly addressed, sustaining turbine operation and preserving investment in the heart of the energy production infrastructure. Expertise, experience, and a commitment to operational excellence drive the ongoing development and optimization of gas turbine air intake filters. The synergy of innovative design, reliability, and unmatched support establishes these filters as indispensable components in the successful operation of gas turbines worldwide.

When selecting an intake filter, operators should rely heavily on systems that have been independently tested and verified. Industry certifications, such as those by ISO (International Organization for Standardization) or ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers), serve as benchmarks for performance reliability and trustworthiness. Certified filters have undergone rigorous evaluations to ensure they meet specific performance standards that safeguard the turbine's operational integrity. Long-term cost efficiency is another critical consideration. While more advanced filters may come with a higher initial price tag, the cost-benefit analysis often reveals savings in reduced downtime, less frequent maintenance, and extended machinery life. Collaborating with manufacturers that provide comprehensive data sheets, performance analytics, and customer testimonials can ensure confidence in the filter’s long-term efficacy. Finally, end-users must prioritize working with manufacturers and suppliers that offer robust after-sales support and technical assistance. Establishing a partnership with a reputable company that stands behind its products with warranties, support services, and expert advice is invaluable. Such alliances ensure any issues are promptly addressed, sustaining turbine operation and preserving investment in the heart of the energy production infrastructure. Expertise, experience, and a commitment to operational excellence drive the ongoing development and optimization of gas turbine air intake filters. The synergy of innovative design, reliability, and unmatched support establishes these filters as indispensable components in the successful operation of gas turbines worldwide.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: