ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 12, 2025 17:49 Back to list

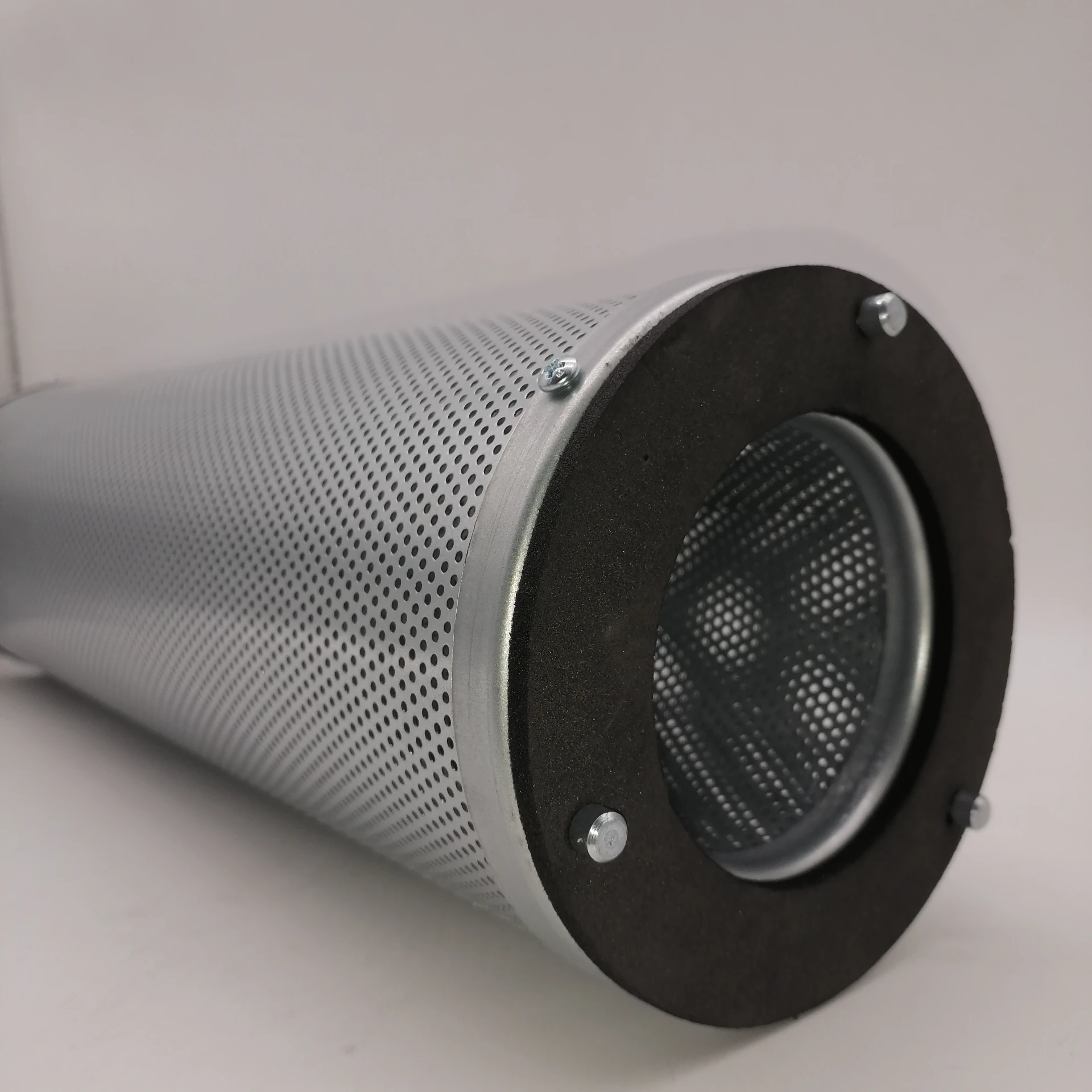

gas turbine air intake filter

Gas turbines serve as the backbone to various industrial operations around the world, but their efficiency heavily relies on one crucial component the air intake filter. This often overlooked element plays a pivotal role in ensuring the smooth operation of gas turbines, protecting them from contaminants, improving performance and longevity.

Authoritative studies by the Gas Turbine Association consistently stress that neglect of air intake systems leads to significantly higher operating costs. Their research shows that in environments where the air is particularly polluted, turbines consume more fuel and operate less efficiently without the right filtration solutions. Operators with experience in diverse environments who switch to optimized air intake filters often witness marked improvements in turbine performance, sometimes up to a 10% efficiency gain purely from using enhanced filtration methods. Trustworthiness in the selection of an air intake filter should not be underestimated. Reputable manufacturers typically certify filters with ISO standards. This certification provides assurance of the filter's ability to withstand the harsh environments typically associated with gas turbines. For industry professionals, opting for filters that meet these standards ensures reliability, safety, and compliance with global operating procedures. Among the best practices observed by experts is the adoption of a predictive maintenance model facilitated by IoT sensors. These sensors monitor air pressure differentials across the filter media, sending proactive alerts about potential blockages or the end of the filter's useful life. This model of maintenance circumvents unexpected shutdowns and contributes to a seamless operational flow which is invaluable to maintaining production schedules and reducing unforeseen expenditure. In conclusion, choosing the right gas turbine air intake filter is integral to maximizing the life and performance of gas turbines. With advancements in technology leading to superior filtration capabilities and an industry-wide move towards smarter maintenance strategies, businesses can achieve greater efficiencies, reduce operational costs, and ensure that their systems are up-to-date with contemporary environmental standards. With the right choices, operators not only ensure the running of efficient turbines but also contribute positively to broader corporate sustainability goals.

Authoritative studies by the Gas Turbine Association consistently stress that neglect of air intake systems leads to significantly higher operating costs. Their research shows that in environments where the air is particularly polluted, turbines consume more fuel and operate less efficiently without the right filtration solutions. Operators with experience in diverse environments who switch to optimized air intake filters often witness marked improvements in turbine performance, sometimes up to a 10% efficiency gain purely from using enhanced filtration methods. Trustworthiness in the selection of an air intake filter should not be underestimated. Reputable manufacturers typically certify filters with ISO standards. This certification provides assurance of the filter's ability to withstand the harsh environments typically associated with gas turbines. For industry professionals, opting for filters that meet these standards ensures reliability, safety, and compliance with global operating procedures. Among the best practices observed by experts is the adoption of a predictive maintenance model facilitated by IoT sensors. These sensors monitor air pressure differentials across the filter media, sending proactive alerts about potential blockages or the end of the filter's useful life. This model of maintenance circumvents unexpected shutdowns and contributes to a seamless operational flow which is invaluable to maintaining production schedules and reducing unforeseen expenditure. In conclusion, choosing the right gas turbine air intake filter is integral to maximizing the life and performance of gas turbines. With advancements in technology leading to superior filtration capabilities and an industry-wide move towards smarter maintenance strategies, businesses can achieve greater efficiencies, reduce operational costs, and ensure that their systems are up-to-date with contemporary environmental standards. With the right choices, operators not only ensure the running of efficient turbines but also contribute positively to broader corporate sustainability goals.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: