ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 12, 2025 20:23 Back to list

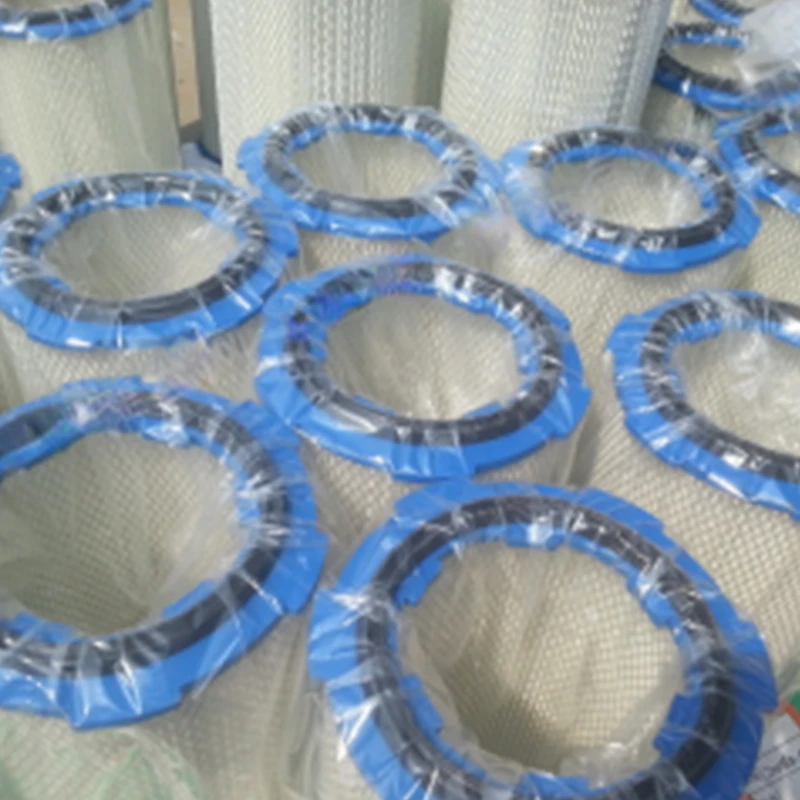

gas turbine air filter manufacturer

Choosing the right gas turbine air filter manufacturer is crucial for industries reliant on efficient energy production and operational reliability. With the increasing emphasis on sustainable practices and cost-effectiveness, understanding the nuances of gas turbine technology and air filtration systems is essential.

Trustworthiness, another critical factor, can be assessed through customer testimonials and long-term reliability data. Manufacturers that maintain transparency in their testing methodologies and provide comprehensive technical support instill confidence in their clientele. Furthermore, a history of successful deployments in diverse operational settings — ranging from power plants to offshore installations — speaks volumes about a manufacturer’s reliability. A notable trend among reputable manufacturers is the emphasis on eco-friendly practices. With the global shift towards reducing carbon footprints, manufacturers are deploying eco-conscious design principles to minimize environmental impact. This includes developing filter solutions that promote energy efficiency and reduce waste during both the production and operational phases. Moreover, the integration of smart technologies into air filter systems is revolutionizing the industry. Innovative manufacturers are embedding IoT sensors into their filters, enabling real-time monitoring of air quality and filter performance. This proactive approach allows for predictive maintenance and timely interventions, thereby reducing downtime and extending the life of the turbine system. In conclusion, selecting a gas turbine air filter manufacturer involves thorough due diligence with focus on their experience, expertise, authoritativeness, and trustworthiness. A blend of innovation, commitment to quality, and sustainable practices ensures not only operational success but also alignment with the future trajectory of energy production technologies. When industries invest in proven and innovative filtering solutions, they are not merely purchasing a product; they are engaging in a partnership that enhances operational resilience and sustainability.

Trustworthiness, another critical factor, can be assessed through customer testimonials and long-term reliability data. Manufacturers that maintain transparency in their testing methodologies and provide comprehensive technical support instill confidence in their clientele. Furthermore, a history of successful deployments in diverse operational settings — ranging from power plants to offshore installations — speaks volumes about a manufacturer’s reliability. A notable trend among reputable manufacturers is the emphasis on eco-friendly practices. With the global shift towards reducing carbon footprints, manufacturers are deploying eco-conscious design principles to minimize environmental impact. This includes developing filter solutions that promote energy efficiency and reduce waste during both the production and operational phases. Moreover, the integration of smart technologies into air filter systems is revolutionizing the industry. Innovative manufacturers are embedding IoT sensors into their filters, enabling real-time monitoring of air quality and filter performance. This proactive approach allows for predictive maintenance and timely interventions, thereby reducing downtime and extending the life of the turbine system. In conclusion, selecting a gas turbine air filter manufacturer involves thorough due diligence with focus on their experience, expertise, authoritativeness, and trustworthiness. A blend of innovation, commitment to quality, and sustainable practices ensures not only operational success but also alignment with the future trajectory of energy production technologies. When industries invest in proven and innovative filtering solutions, they are not merely purchasing a product; they are engaging in a partnership that enhances operational resilience and sustainability.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: