ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 14, 2025 09:27 Back to list

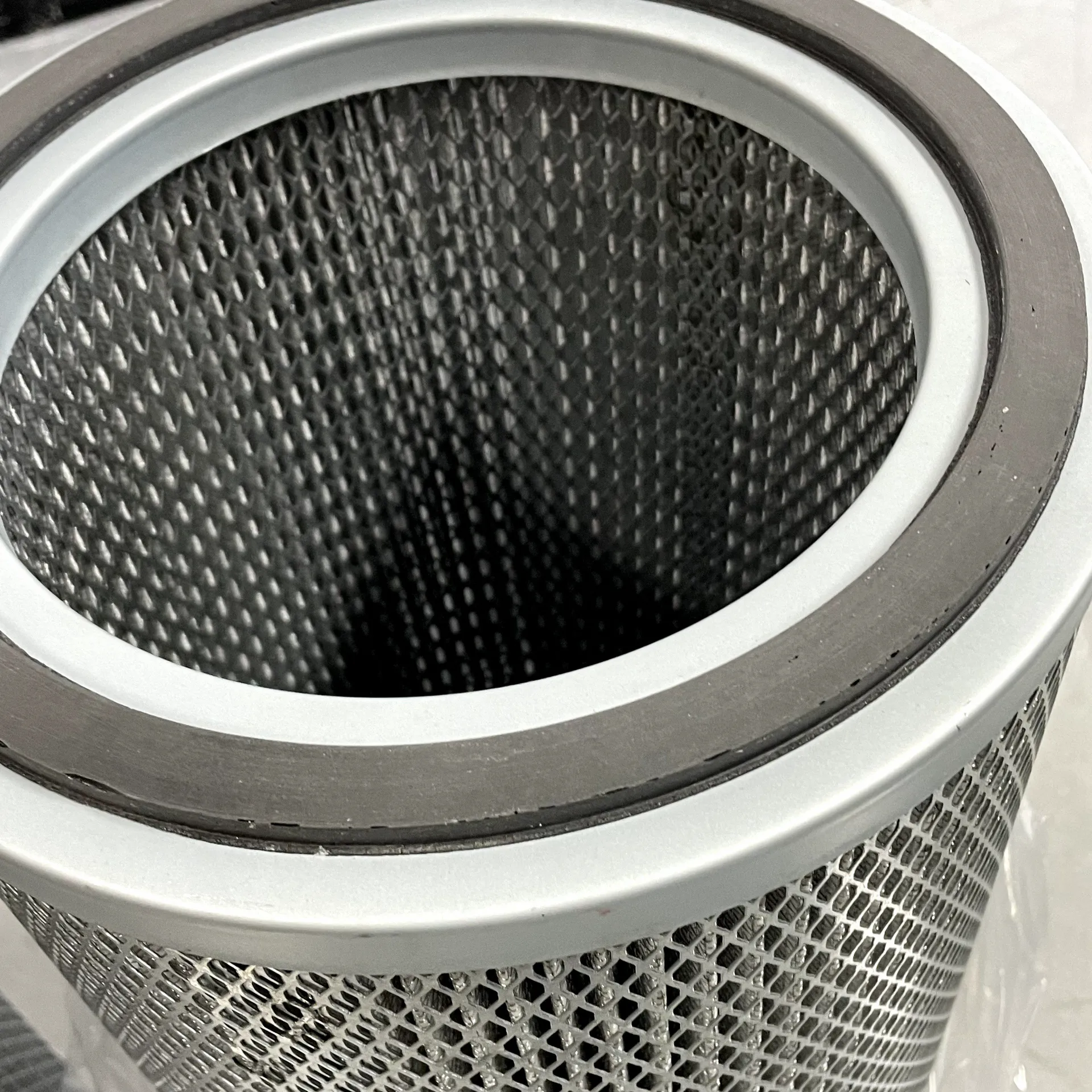

forklift air filter

Forklift air filters are pivotal components that directly influence the performance and longevity of material handling equipment. Their role in ensuring clean airflow to the engine can significantly impact the machine's efficiency and durability. For those who operate forklifts regularly or manage a fleet of them, understanding the nuances of these filters is crucial to maintaining optimal operational standards.

Innovative advancements in air filter technology are also worth noting. Recent developments have introduced high-efficiency particulate air (HEPA) filters into forklifts, which are traditionally used in environments requiring high air purity standards, such as cleanrooms and medical facilities. Although these filters are more expensive, they are unrivaled in filtration capacity, capturing even the smallest particles with impressive efficiency. For industries where air quality is paramount, investing in such technology might prove beneficial not only for the machine but also for the health of personnel working around them. Furthermore, integrating air filter sensors into forklifts is a cutting-edge approach that enhances maintenance effectiveness. These sensors continuously monitor the condition of the air filter, providing real-time data and alerts when a replacement is due. This technology optimizes maintenance schedules and prevents oversight, thus ensuring that the forklift operates at peak performance with minimal downtime. Finally, education and training are essential for those responsible for the maintenance of forklifts. Understanding the various types of air filters, their specific applications, and maintenance requirements empowers operators to make informed decisions that uphold the equipment’s operational integrity. Manufacturers often provide comprehensive training resources to ensure that operators are equipped with the necessary knowledge and skills. In conclusion, forklift air filters are more than mere components; they are vital to an efficient and dependable forklift fleet. By prioritizing quality materials, embracing technological advancements, and investing in knowledge, companies can safeguard their assets and ensure seamless operations. This not only enhances productivity but also prolongs the life expectancy of their equipment, ultimately leading to a more robust bottom line.

Innovative advancements in air filter technology are also worth noting. Recent developments have introduced high-efficiency particulate air (HEPA) filters into forklifts, which are traditionally used in environments requiring high air purity standards, such as cleanrooms and medical facilities. Although these filters are more expensive, they are unrivaled in filtration capacity, capturing even the smallest particles with impressive efficiency. For industries where air quality is paramount, investing in such technology might prove beneficial not only for the machine but also for the health of personnel working around them. Furthermore, integrating air filter sensors into forklifts is a cutting-edge approach that enhances maintenance effectiveness. These sensors continuously monitor the condition of the air filter, providing real-time data and alerts when a replacement is due. This technology optimizes maintenance schedules and prevents oversight, thus ensuring that the forklift operates at peak performance with minimal downtime. Finally, education and training are essential for those responsible for the maintenance of forklifts. Understanding the various types of air filters, their specific applications, and maintenance requirements empowers operators to make informed decisions that uphold the equipment’s operational integrity. Manufacturers often provide comprehensive training resources to ensure that operators are equipped with the necessary knowledge and skills. In conclusion, forklift air filters are more than mere components; they are vital to an efficient and dependable forklift fleet. By prioritizing quality materials, embracing technological advancements, and investing in knowledge, companies can safeguard their assets and ensure seamless operations. This not only enhances productivity but also prolongs the life expectancy of their equipment, ultimately leading to a more robust bottom line.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: