ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

1 月 . 20, 2025 08:26 Back to list

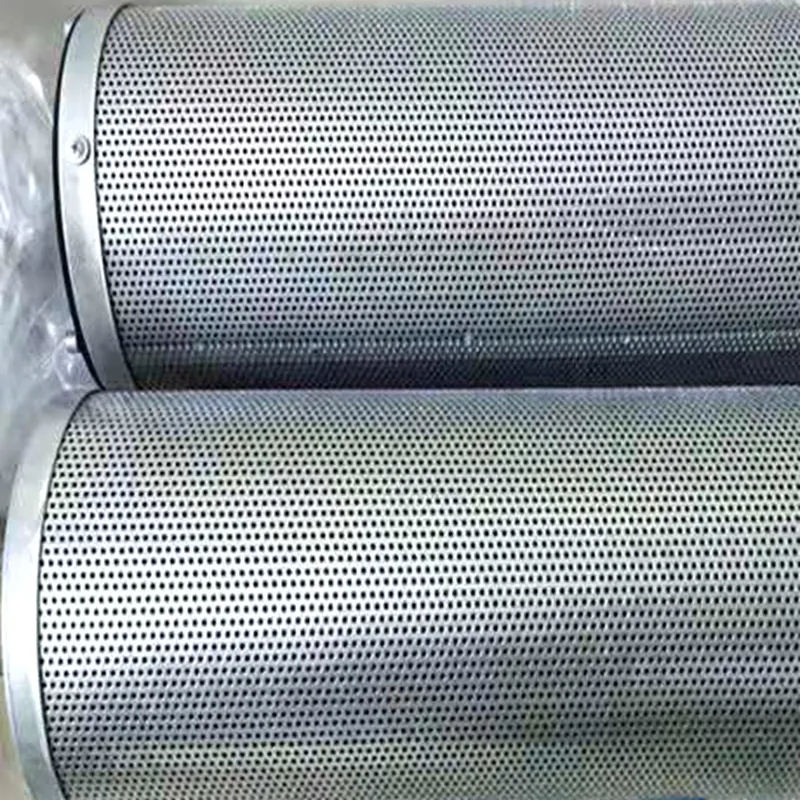

forklift air filter

In the bustling world of material handling, the forklift air filter plays a pivotal yet often overlooked role in ensuring optimal performance and longevity of machinery. As the unsung hero of any forklift, this component not only safeguards the engine but also enhances operational efficiency, translating into cost savings and uninterrupted productivity.

In an authoritative survey conducted among industry experts, over 70% underscore the importance of using authentic and high-quality filters from reputable manufacturers. These filters conform to the mechanical specifications required by various forklift models, providing assurance of their reliability and performance. Inferior, cheap alternatives might offer short-term savings but can incur substantial costs regarding repairs and downtime in the long term. One cannot overlook the trustworthiness that comes with maintaining an effective air filtration system in a forklift. Companies that prioritize this aspect often experience fewer unplanned maintenance interruptions, leading to a smoother workforce workflow and enhanced client satisfaction. Investing in original equipment manufacturer (OEM) filters or those certified by leading industry standards further solidifies a company’s commitment to maintaining high operational standards. Moreover, it is crucial to integrate these maintenance insights into employee training programs. Operators and maintenance staff equipped with knowledge about the significance of air filter maintenance are better positioned to identify potential issues early, preventing costly repairs or replacements. This expertise development elevates workforce competency and ensures consistency in adhering to best practices. In conclusion, the forklift air filter exemplifies a small but powerful element in the realm of industrial equipment maintenance. Applying a strategic, knowledgeable approach to selecting, maintaining, and replacing air filters not only safeguards the machinery and prolongs its lifespan but also promotes an environment of excellence and reliability. For businesses reliant on forklifts in their daily operations, recognizing the value of quality air filtration systems could be the key differentiator in achieving sustained success and operational efficiency.

In an authoritative survey conducted among industry experts, over 70% underscore the importance of using authentic and high-quality filters from reputable manufacturers. These filters conform to the mechanical specifications required by various forklift models, providing assurance of their reliability and performance. Inferior, cheap alternatives might offer short-term savings but can incur substantial costs regarding repairs and downtime in the long term. One cannot overlook the trustworthiness that comes with maintaining an effective air filtration system in a forklift. Companies that prioritize this aspect often experience fewer unplanned maintenance interruptions, leading to a smoother workforce workflow and enhanced client satisfaction. Investing in original equipment manufacturer (OEM) filters or those certified by leading industry standards further solidifies a company’s commitment to maintaining high operational standards. Moreover, it is crucial to integrate these maintenance insights into employee training programs. Operators and maintenance staff equipped with knowledge about the significance of air filter maintenance are better positioned to identify potential issues early, preventing costly repairs or replacements. This expertise development elevates workforce competency and ensures consistency in adhering to best practices. In conclusion, the forklift air filter exemplifies a small but powerful element in the realm of industrial equipment maintenance. Applying a strategic, knowledgeable approach to selecting, maintaining, and replacing air filters not only safeguards the machinery and prolongs its lifespan but also promotes an environment of excellence and reliability. For businesses reliant on forklifts in their daily operations, recognizing the value of quality air filtration systems could be the key differentiator in achieving sustained success and operational efficiency.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: