Tel:

+8618931101301

Tel:

+8618931101301

8 月 . 17, 2024 18:30 Back to list

Exploring the Benefits of Dust Cartridge Filtration Systems for Clean Air Quality

Understanding Dust Percentage in Cartridge Filters

In industrial and commercial environments, maintaining air quality is crucial, especially when dealing with processes that produce dust and particulate matter. One of the practical solutions employed to combat airborne pollutants is the use of cartridge filters. These filters are designed to capture dust particles efficiently, but one important aspect to consider is the dust percentage in cartridge filters, which can significantly influence their performance and lifespan.

What is Dust Percentage?

Dust percentage refers to the amount of particulate matter that the cartridge filter can collect compared to its total capacity. It is vital for determining how much dust the filter can handle before it becomes clogged or less efficient. The measurement of dust percentage can provide insights into the filter's effectiveness, performance under various loads, and the frequency at which it needs to be replaced or cleaned.

Importance of Monitoring Dust Percentage

Monitoring the dust percentage in cartridge filters is essential for several reasons. Firstly, it helps in maintaining optimal airflow within the system. As the filter captures dust, it gradually becomes saturated. If not monitored, a clogged filter can lead to increased resistance against the airflow, forcing the system to work harder and potentially increasing energy costs.

Secondly, understanding the dust percentage can aid in scheduling maintenance more effectively. Regularly utilizing filters close to their capacity may result in premature wear and tear, leading to the need for more frequent replacements. By keeping track of dust levels, operators can ensure that the filters are cleaned or replaced just in time, maximizing the lifespan of the equipment.

Factors Affecting Dust Percentage

Several factors affect the dust percentage of cartridge filters, including air quality, the type of contaminants present, and the filter's design. For instance, environments with high dust loads, such as woodworking shops or construction sites, will likely see filters reach their dust percentage limits much faster. Conversely, clean environments with less airborne particulate matter will result in lower dust accumulation.

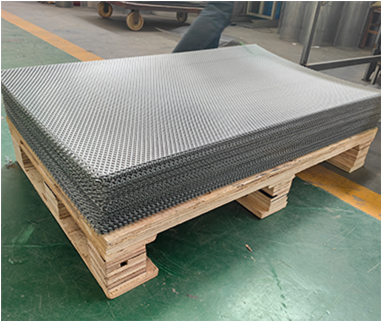

dust cartridge

The filter's design also plays a pivotal role in its dust percentage capacity. Some cartridges come equipped with advanced filtering materials or structures that are more effective at capturing finer particles. Choosing the right filter for the specific application can optimize dust retention and enhance overall system efficiency.

Tips for Managing Dust Percentage

To effectively manage dust percentages in cartridge filters, several best practices can be followed

1. Regular Monitoring Implement a schedule for checking dust levels in filters. This can include visual inspections, pressure drop measurements, and even more sophisticated monitoring systems that alert operators when filters are nearing saturation.

2. Choose Quality Filters Investing in high-quality cartridge filters that are designed for specific dust types can enhance performance and extend filter life.

3. Maintain Cleanliness Keep the surrounding area clean to minimize dust accumulation on filters. This reduces the load on the cartridges and promotes better airflow.

4. Educate Personnel Ensure that all operators involved in maintenance acknowledge the importance of maintaining optimal dust percentage levels and understand how to monitor and manage them effectively.

In conclusion, understanding dust percentage in cartridge filters is crucial for ensuring efficient operation and air quality management in various applications. By regularly monitoring this metric and implementing best practices, businesses can extend the life of their filters, reduce operational costs, and create a safer work environment.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: