ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 14, 2025 07:17 Back to list

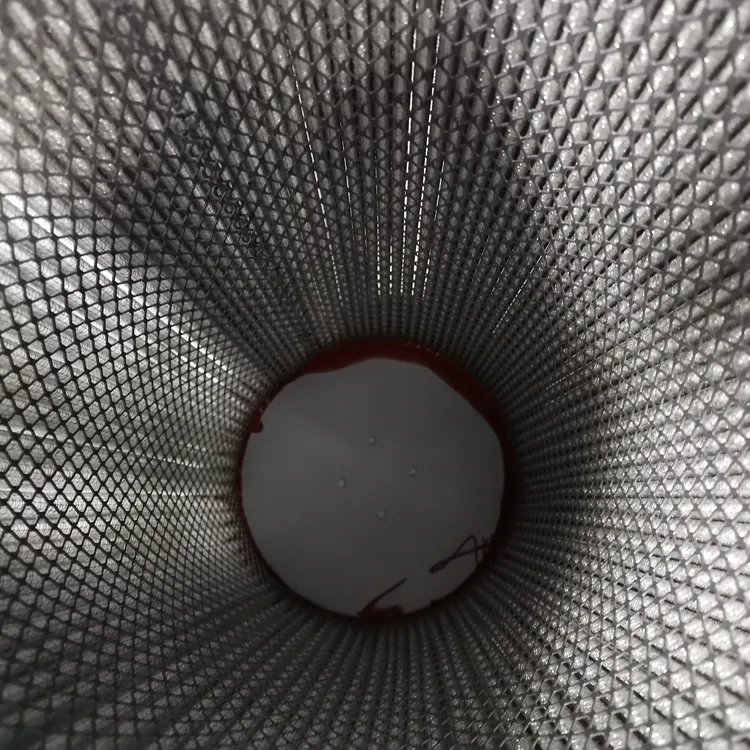

excavator air filter

Choosing the right air filter is crucial for ensuring the optimal performance and longevity of your excavator's engine. Operators often overlook the importance of this small yet vital component, but its role in machine efficiency and maintenance costs can't be overstated. This article delves into the intricate world of excavator air filters, drawing on years of industry experience and expertise to provide actionable insights and authoritative recommendations for maintaining trust in your equipment.

Proper installation and maintenance are paramount for sustaining an air filter's effectiveness. During installation, ensure a secure fit to avoid unfiltered air bypass. Routine inspections should involve checking for physical damage, saturation, or clogging. Replace the air filter at intervals recommended by the manufacturer, or more frequently in particularly harsh environments. Ignoring maintenance schedules can lead to filter breaches and subsequent engine damage. Investing in pre-cleaners can extend the life of your air filter. These devices capture large debris before it reaches the primary filter. They are particularly beneficial in dust-heavy environments and can significantly reduce maintenance efforts and costs. Enhancing Trust Through Industry Innovations Innovation in air filtration technology continues to advance. Modern filters offer features such as integrated sensors to monitor filter condition, alerting operators when replacements are necessary. This advancement not only ensures optimal engine performance but also enhances the trustworthiness of your machinery. Furthermore, embracing cutting-edge materials and designs is setting new standards in the industry. Nanofiber technology, for example, offers enhanced durability and superior filtration capabilities, proving invaluable for heavy-duty operations. By staying informed about these innovations, operators can ensure that their equipment benefits from the latest advancements in air filtration technology. Conclusion Paying close attention to your excavator's air filters is a small investment that yields significant returns in performance, reliability, and engine lifespan. By integrating the right air filter solution suited to your working conditions, alongside conscientious maintenance practices, you not only optimize the performance of your excavator but also establish a trustworthy reputation for your equipment in the competitive landscape. Through expert advice and authoritative knowledge, operators can ensure their machinery continues to deliver exceptional results in any environment.

Proper installation and maintenance are paramount for sustaining an air filter's effectiveness. During installation, ensure a secure fit to avoid unfiltered air bypass. Routine inspections should involve checking for physical damage, saturation, or clogging. Replace the air filter at intervals recommended by the manufacturer, or more frequently in particularly harsh environments. Ignoring maintenance schedules can lead to filter breaches and subsequent engine damage. Investing in pre-cleaners can extend the life of your air filter. These devices capture large debris before it reaches the primary filter. They are particularly beneficial in dust-heavy environments and can significantly reduce maintenance efforts and costs. Enhancing Trust Through Industry Innovations Innovation in air filtration technology continues to advance. Modern filters offer features such as integrated sensors to monitor filter condition, alerting operators when replacements are necessary. This advancement not only ensures optimal engine performance but also enhances the trustworthiness of your machinery. Furthermore, embracing cutting-edge materials and designs is setting new standards in the industry. Nanofiber technology, for example, offers enhanced durability and superior filtration capabilities, proving invaluable for heavy-duty operations. By staying informed about these innovations, operators can ensure that their equipment benefits from the latest advancements in air filtration technology. Conclusion Paying close attention to your excavator's air filters is a small investment that yields significant returns in performance, reliability, and engine lifespan. By integrating the right air filter solution suited to your working conditions, alongside conscientious maintenance practices, you not only optimize the performance of your excavator but also establish a trustworthy reputation for your equipment in the competitive landscape. Through expert advice and authoritative knowledge, operators can ensure their machinery continues to deliver exceptional results in any environment.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: