ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

1 月 . 26, 2025 02:20 Back to list

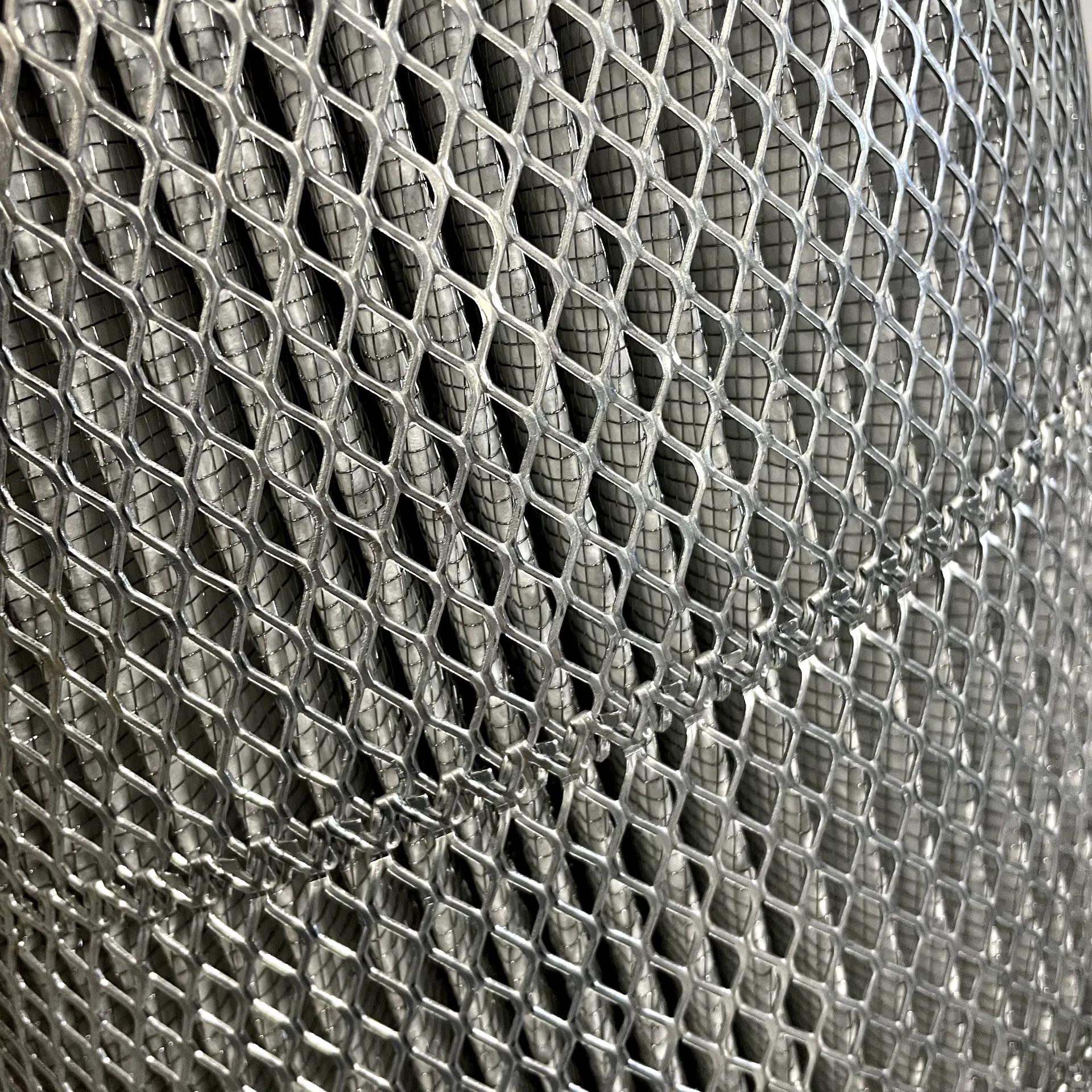

Low cost durable air filter for gas turbine

In the world of heavy machinery, particularly within the realm of excavators, the role of an air filter is both crucial and often underestimated. Overshadowed by more visible components like the boom and bucket, the air filter performs silently, ensuring that the enormous diesel engine breathes cleanly and efficiently. Before delving into specific product recommendations, let’s consider the broader significance of air filters in excavators, blending both personal experience and expert insights.

Authoritative bodies in the industry, such as the Association of Equipment Manufacturers (AEM), underscore the importance of using OEM (Original Equipment Manufacturer) air filters whenever possible. These filters are tailored to the specific make and model of the excavator, ensuring optimal fit and performance. While aftermarket alternatives are available, they can pose risks if compatibility and performance aren't thoroughly vetted. Personal experience affirms that cutting costs at the expense of quality rarely pays off, especially in scenarios where machinery downtime equals significant financial loss. Trust is another cornerstone in selecting an air filter, further amplifying the choice of sticking with reputable brands. A trusted air filter undergoes rigorous quality control processes and adheres to stringent industry standards, providing assurance against performance failures. For those managing fleets of excavators, trust extends to consistency across purchases—a consistent supply chain of reliable parts translates to smoother operations and predictable maintenance schedules. In summation, while the air filter may not share the spotlight with more recognizable components, its impact is undeniably substantial. Excavators, thriving amidst dirt and debris, depend on these devices to maintain peak operational performance. A small investment in a high-quality air filter can safeguard against unplanned repairs and extend the engine's life span. For those immersing themselves in the complexities of maintaining heavy machinery, remember that while all parts have a role, some—like the air filter—are the unsung heroes ensuring that the work continues seamlessly.

Authoritative bodies in the industry, such as the Association of Equipment Manufacturers (AEM), underscore the importance of using OEM (Original Equipment Manufacturer) air filters whenever possible. These filters are tailored to the specific make and model of the excavator, ensuring optimal fit and performance. While aftermarket alternatives are available, they can pose risks if compatibility and performance aren't thoroughly vetted. Personal experience affirms that cutting costs at the expense of quality rarely pays off, especially in scenarios where machinery downtime equals significant financial loss. Trust is another cornerstone in selecting an air filter, further amplifying the choice of sticking with reputable brands. A trusted air filter undergoes rigorous quality control processes and adheres to stringent industry standards, providing assurance against performance failures. For those managing fleets of excavators, trust extends to consistency across purchases—a consistent supply chain of reliable parts translates to smoother operations and predictable maintenance schedules. In summation, while the air filter may not share the spotlight with more recognizable components, its impact is undeniably substantial. Excavators, thriving amidst dirt and debris, depend on these devices to maintain peak operational performance. A small investment in a high-quality air filter can safeguard against unplanned repairs and extend the engine's life span. For those immersing themselves in the complexities of maintaining heavy machinery, remember that while all parts have a role, some—like the air filter—are the unsung heroes ensuring that the work continues seamlessly.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: