ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 06, 2025 01:26 Back to list

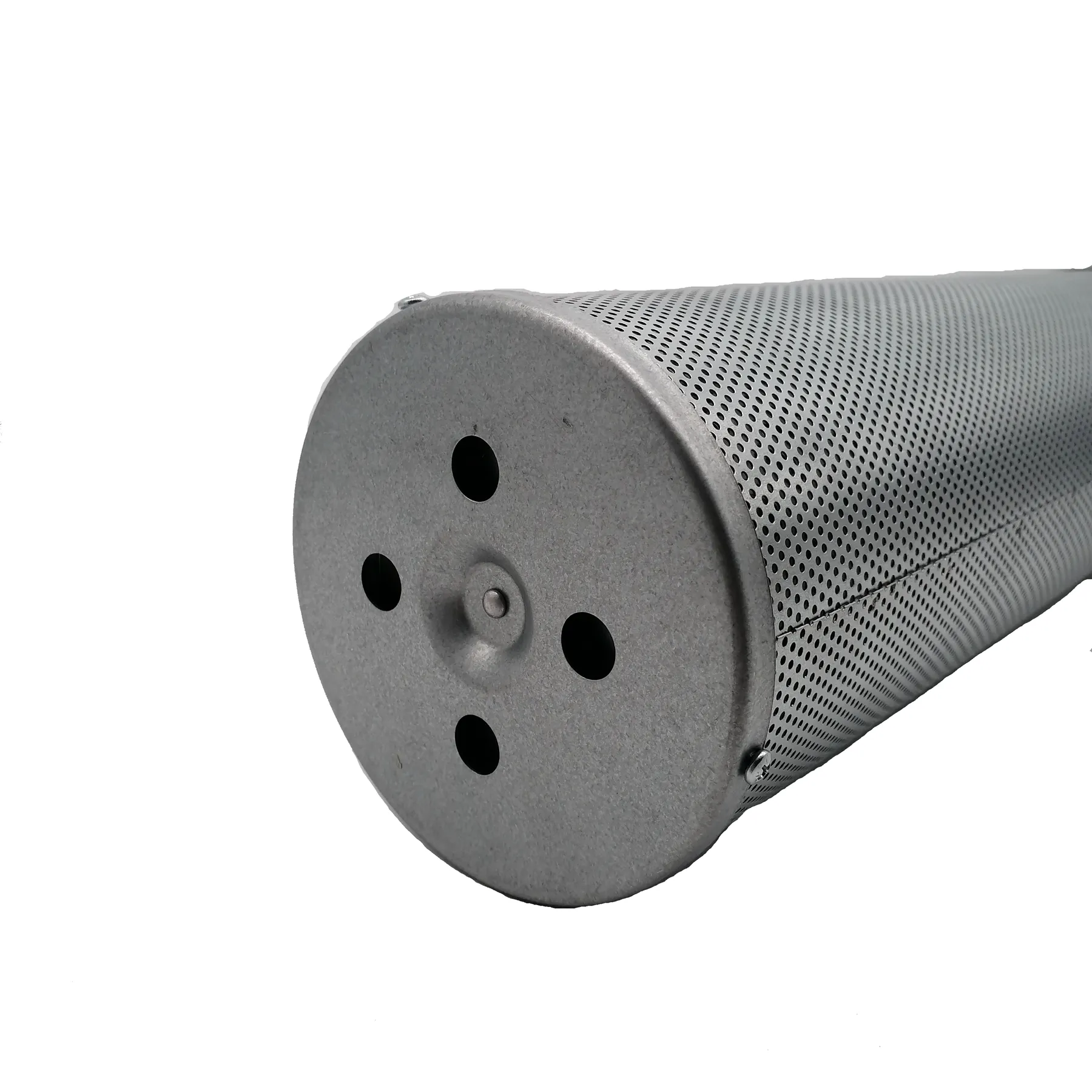

dust extractor pleated filter cartridges

Dust extractor pleated filter cartridges play a pivotal role in maintaining the efficiency and longevity of industrial dust collection systems. These components are not only engineered to enhance air quality but also crucial in safeguarding machinery and ensuring a healthy working environment. As industries evolve, the demand for highly efficient dust management solutions becomes indispensable. Leveraging both advanced technology and profound expertise, companies can significantly benefit from incorporating pleated filter cartridges into their dust extraction systems.

In terms of authoritativeness, leading manufacturers in this sector conduct rigorous testing and certification processes to validate the performance of their filter cartridges. Compliance with international standards such as ISO and ASHRAE assures customers of the product's reliability and effectiveness. Furthermore, manufacturers often collaborate with environmental agencies to develop innovative solutions that meet evolving regulatory requirements. Trust in pleated filter cartridges is established through consistent performance and longevity. End-users report significant reductions in equipment downtime and maintenance costs, which contributes to increased productivity and profitability. Testimonials and case studies from reputable sources further solidify the credibility of these products. Additionally, companies often offer comprehensive warranties and technical support, providing users with confidence in their investment. For businesses considering the integration of pleated filter cartridges, expert consultation is recommended to assess specific dust extraction needs and system compatibility. Factors such as dust particle size, temperature, humidity, and chemical composition must be carefully evaluated to select the right filter media and design. Engaging with industry experts can provide invaluable insights into optimizing system performance and achieving environmental compliance. In summary, dust extractor pleated filter cartridges are an essential component for efficient industrial dust management. Their advanced design, coupled with expert manufacturing processes, ensures superior filtration and energy efficiency. With growing awareness of environmental health and safety standards, these cartridges provide a reliable solution for diverse industries. By investing in such technology, companies not only enhance their operational efficiency but also demonstrate a commitment to sustainable and conscientious industry practices.

In terms of authoritativeness, leading manufacturers in this sector conduct rigorous testing and certification processes to validate the performance of their filter cartridges. Compliance with international standards such as ISO and ASHRAE assures customers of the product's reliability and effectiveness. Furthermore, manufacturers often collaborate with environmental agencies to develop innovative solutions that meet evolving regulatory requirements. Trust in pleated filter cartridges is established through consistent performance and longevity. End-users report significant reductions in equipment downtime and maintenance costs, which contributes to increased productivity and profitability. Testimonials and case studies from reputable sources further solidify the credibility of these products. Additionally, companies often offer comprehensive warranties and technical support, providing users with confidence in their investment. For businesses considering the integration of pleated filter cartridges, expert consultation is recommended to assess specific dust extraction needs and system compatibility. Factors such as dust particle size, temperature, humidity, and chemical composition must be carefully evaluated to select the right filter media and design. Engaging with industry experts can provide invaluable insights into optimizing system performance and achieving environmental compliance. In summary, dust extractor pleated filter cartridges are an essential component for efficient industrial dust management. Their advanced design, coupled with expert manufacturing processes, ensures superior filtration and energy efficiency. With growing awareness of environmental health and safety standards, these cartridges provide a reliable solution for diverse industries. By investing in such technology, companies not only enhance their operational efficiency but also demonstrate a commitment to sustainable and conscientious industry practices.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: